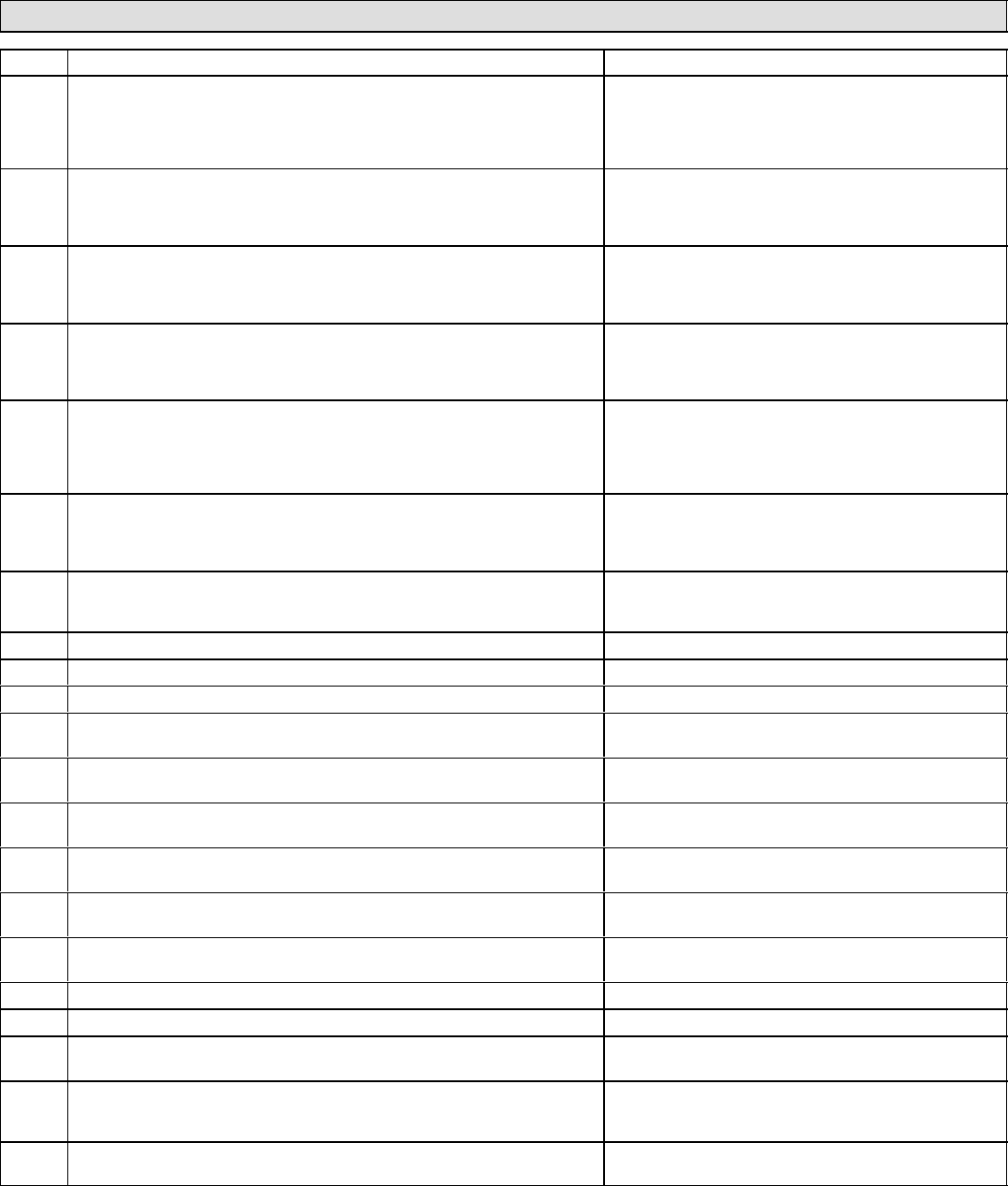

Page 54

Integrated Control Diagnostic Codes (continued)

Code Diagnostic Codes/Status of Equipment Action Required to Clear and Recover

E 223

Low pressure switch failed open − Refer to troubleshooting in installation

instruction.

Check inches of water column pressure during operation

of low pressure switch on heat call, measure inches of

water column of operating pressure, inspect vent and

combustion air inducer for correct operation and restric-

tion.

E 224

Low pressure switch failed closed − Refer to troubleshooting in installation

instruction.

Check low pressure switch for closed contacts, measure

inches of water column of operating pressure, inspect vent

and combustion air inducer for correct operation and re-

striction.

E 225

High pressure switch failed open − Refer to troubleshooting in installation

instruction.

Check inches of water column pressure of high pressure

switch on heat call, measure inches of water column of

operating pressure, inspect vent and combustion air

inducer for correct operation and restriction.

E 226

High pressure switch failed closed − Refer to troubleshooting in installation

instruction.

Check high pressure switch for closed contacts, measure

inches of water column of operating pressure, inspect vent

and combustion air inducer for correct operation and

restriction.

E 227

Low pressure switch open during trial for ignition or run mode. Refer to trouble-

shooting in installation instruction.

Check inches of water column pressure during operation

of low pressure switch on heat call, measure inches of

water column of operating pressure, inspect vent and

combustion air inducer for correct operation and restric-

tion.

E 228

Unable to perform successful pressure switch calibration. Retry after 300 seconds. Error counter cleared when exit-

ing lockout, unable to perform pressure switch calibration.

Check vent system and pressure switch wiring

connections.

E 240

Low flame current − Run mode − Refer to troubleshooting in

installation instruction.

Check micro amperes of flame sensor, clean or replace

sensor. Measure voltage of neutral to ground for good unit

ground.

E 241

Flame sensed out of sequence − Flame still present. Shut off gas, check for gas valve leak.

E 250

Limit switch circuit open − Refer to troubleshooting in installation instruction. Check why limit is tripping, overfired, low air flow.

E 252

Discharge air temperature too high (gas heat only). Check temperature rise, air flow and input rate.

E 270

Soft lockout − Exceeded maximum number of retries. No flame current sensed. Check for gas flow, ignitor lighting burner, flame sensor

current.

E 271

Soft lockout − Exceeded maximum number of retries. Last retry failed due to

the pressure switch opening.

See E 223.

E 272

Soft lockout − Exceeded maximum number of recycles. Last recycle due to the

pressure switch opening.

See E 223 and E 225.

E 273

Soft lockout − Exceeded maximum number of recycles. Last recycle due to

flame failure.

See E 240.

E 274

Soft lockout − Exceeded maximum number of recycles. Last recycle failed due

to the limit circuit opening or limit remained open longer than 3 minutes.

See E 250.

E 275

Soft lockout − Flame sensed out of sequence from code 241 fault. Flame signal

is gone.

See E 241.

E 276

Soft lockout − Exceeded maximum number of calibration retries. See E 228.

E 290

Ignitor circuit fault − Failed ignitor or triggering circuitry. See E 207.

E 291

Restricted air flow − Cubic feet per minute is lower than what is needed for

minimum firing rate.

Check for dirty filter, unit air flow restriction, blower

performance.

E 292

Indoor blower motor unable to start − Seized bearings, stuck wheel, etc. Indoor blower motor unable to start (seized

bearing, stuck wheel, etc), replace motor or wheel if

assembly does not operate or meet performance.

E 294

Combustion air inducer motor amp draw is too high. Check combustion blower bearings, wiring , amperes,

replace if it does not operate or meet performance.