S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

69-2076—01 12

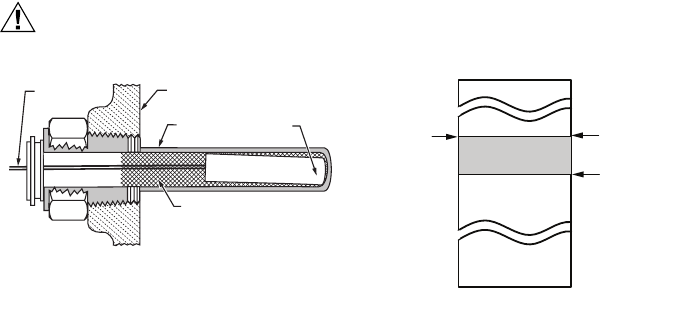

Mounting Sensor and Thermowell

The remote upper temperature sensor is installed in an

immersion well (Fig. 8) that extends into the supply water

side of the boiler.

Immersion Well Fitting

The immersion well must snugly fit the sensing bulb for

good thermal response. Install as follows:

1. Use tapping provided by tank manufacturer, if pos-

sible, or select an area where typical water temper-

ature is best measured.

2. If tank is filled, drain to below point where bulb will

be installed.

3. Screw well into tank.

4. Insert bulb into well, pushing wires until bulb bot-

toms in well.

5. Attach mounting clamp end of well spud.

6. With mounting clamp attached to well spud (make

sure jaws of clamp hook over ridge at end of spud,

as shown at points A in Fig. 8), adjust sensing lead-

wire to fit through mounting clamp groove, as

shown at point B in Fig. 8.

7. Tighten draw nut until mounting clamp is firmly

attached to well spud and wires are held securely in

place.

CAUTION

Do not secure draw nut so tightly that

mounting clamp collapses tubing.

Fig. 8. Immersion well fitting for sensor.

Wiring

Disconnect power supply before installation to prevent

electrical shock or equipment damage. All wiring must

comply with local codes and ordinances regarding wire

size, type of insulation, enclosure, etc.

OPERATION AND CHECKOUT

Operation

The S9360A, S9361A, S9370A and S9371A continuously

monitor the temperature of the boiler water and enable or

disable the burner based on this temperature data. In

general, when a “Call for Heat” occurs, the ignition portion

of the control module proceeds through the steps

necessary to start the burner and heats the water in the

boiler until the setpoint temperature is achieved. At this

point the burner is de-activated, the ignition module

completes the heating cycle, returns to idle and waits for

the temperature to drop again. The circulator is turned on

throughout the “Call for Heat.”

See Fig. 9 for a graphical representation of a simple

control cycle. Note that the setpoint differential may vary

based on OS number.

High Limit Controller

All models include a 3-wire temperature sensor interface,

“Sensor 1,” which is utilized for High Limit functionality in

addition to the thermostatic control of the water heater

burner. If the temperature sensor ever indicates a

temperature above the maximum limit then the control

enters over temperature mode. In over temperature mode

no heating will occur.

Fig. 9. Basic control algorithm example.

SENSOR WIRES

M23086A

HEAT-CONDUCTIVE COMPOUND

(OPTIONAL)

BOILER

IMMERSION

WELL

SENSOR

M27000

SETPOINT

GAS VALVE OFF

GAS VALVE ON

70°F (21°C)

200°F (93.3°C)

15°F (8°C)

DIFFERENTIAL