68-0173—3 34

Table 10. Heat Pump System Checkout.

a

a

The polarity configuration of the reversing valve relay (O/B) determines if the O/B is always energized on first call for heat or

cool. If the reversing valve energizes with heat, then it de-energizes with cooling. Factory setting is for O/B to energize with a

call for heat.

b

O/B is energized based on installer setup or configuration.

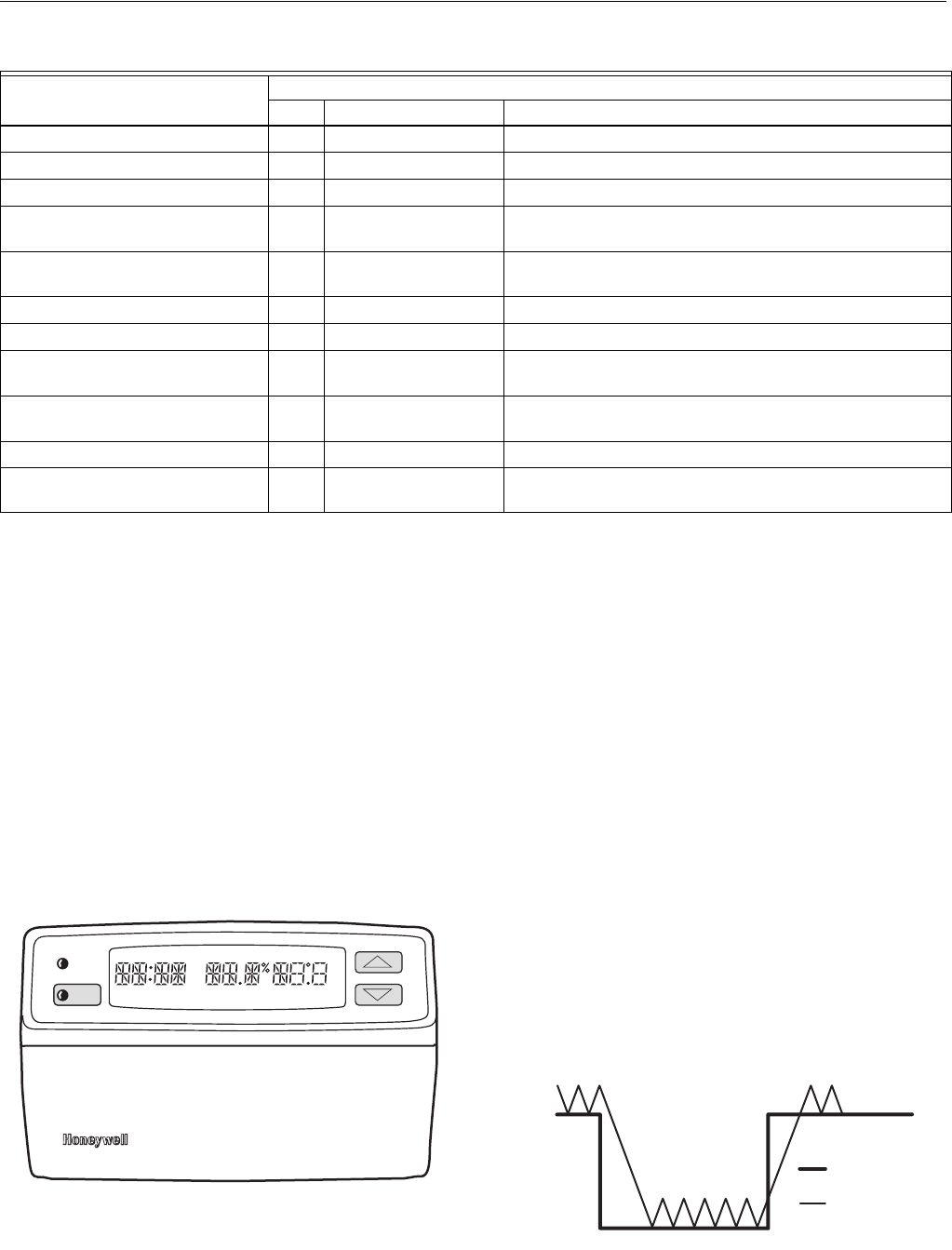

Installer Display of all Segments and Product Codes

(Optional)

1. Press and hold CHECK key until all segments of the dis-

play are lighted. See Fig. 31.

2. Press the CHECK key four more times to view each of

the following items:

— Order specification number of the Comfort Center™

control system.

— Manufacturing date code and software revision

numbers of the Comfort Center™ control system.

— Order specification number of the remote module.

— Manufacturing date code and software revision

numbers of the remote module.

3. Press the CHECK key to return to normal operation.

Fig. 31. All segments on display.

OPERATION

The PC8900A, C7089A, C7189A, C7100A and CO

2

monitor

sense the temperature, humidity and CO

2

conditions in the

living space. This information is then transferred to the

W8900A-C Remote Module, which activates the proper

equipment based on the programmed settings.

Conventional vs. Adaptive Intelligent

Recovery™ Operation

Conventional Recovery

Conventional temperature recovery starts the heating or

cooling system at the programmed set time. See Fig. 32.

Using conventional recovery requires setting the program

period times earlier than the area is occupied so the area will

be comfortable. The program may need to be adjusted

periodically to accommodate for weather and seasonal

changes. The conventional recovery method is used when

Adaptive Intelligent Recovery™ operation is disabled.

Fig. 32. Conventional recovery ramp.

Step

Result

LED Terminals Energized Equipment Operation

Remove jumper from T terminal. Off G Fan relay is energized.

Reconnect jumper to T terminal. On

G, W1/Y1, O/B

b

Fan and first-stage heat are energized.

Remove jumper from T terminal. Off

G, W1/Y1, W2, O/B

b

Fan, first- and second-stage heat are energized.

Reconnect jumper to T terminal. On G, W1/Y1, W2, AUX,

O/B

b

Fan, first-, second- and auxiliary-stage heat are energized.

Remove jumper from T terminal. Off

G, E, O/B

b

First- and second-stage heat are de-energized. Fan and

emergency heat are energized.

Reconnect jumper to T terminal. On

G, W1/Y1, O/B

b

Fan and first-stage cooling are energized.

Remove jumper from T terminal. Off

G, W1/Y1, Y2, O/B

b

Fan, first- and second-stage cooling are energized.

Reconnect jumper to T terminal. On

G, W1/Y1, Y2, O/B

b

,

HUM

Fan, first- and second-stage cooling with the humidifier are

energized.

Remove jumper from T terminal. Off

G, W1/Y1, Y2, O/B

b

,

HUM, VNT

Fan, first- and second-stage cooling with the humidifier and

VNT are energized.

Reconnect jumper to T terminal. On None All equipment is de-energized.

Remove jumper from T1, S and S1

terminals.

On None Returns PC8900A to normal operation.

SYSTEM OFF AUTO

SUN MON TUE WED THU FRI SAT WAKELEAVERETURNSLEEP TEMPORARY VENT

AM

PM

AUTO

ON

CIRC

FAN

AUX HEAT SET PT COOL SET PT

M6400

SYSTEM

CHECK

70 F

60 F

SLEEP

WAKE

SETPOINT

TEMPERATURE

ACTUAL

TEMPERATURE

M6404