C7015A

INSTALLATION

l

ADUSTMENTS AND CHECKOUT

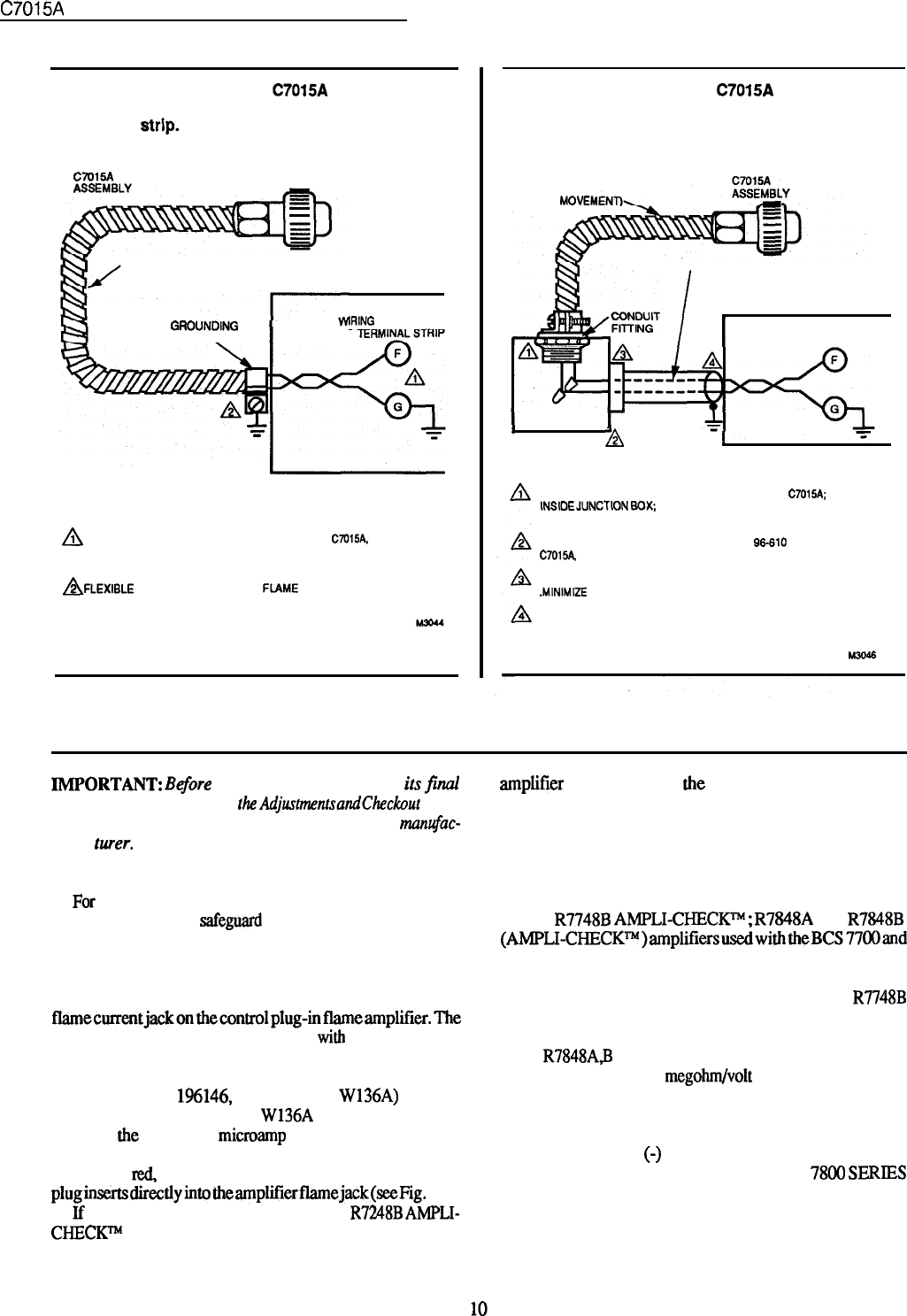

Fig. 1 O-Typical wiring of

C7015A

Infrared

Fig. 1 l-Typical wiring of

C7015A

Infrared

Flame Detector to nearby wiring subbase or Flame Detector to distant wiring subbase or

terminal

strip.

terminal strip.

cmi5A

FLEXIBLE CABLE

(MECHANICALLY

SUPPORT TO

MINIMIZE

MOVEh

FLEXIBLE CABLE (MECHANICALLY

SUPPORT TO MINIMIZE MOVEMENT)

BX CABLE, SHIELDED

CABLE, OR TWISTED

PAIR; MUST BE ALONE

I

I

IN CONDUIT.

FLAME SAFEGUARD

CONTROLS SUBBASE

RING

SUBBASE

GROUNDlNG

STRAP,

OR

TERh

n

1

1 BROWN WIRE AND 1 WHITE WIRE FROM THE

C7015A.

CONNECT TO

FLAME SAFEGUARD CONTROL’S SUBBASE, COLOR NOT IMPORTANT,

KEEP WIRES AS SHORT AS POSSIBLE. AND TWIST THEM.

AFLEXIBLE

CABLE MUST BE RUN To

FLAME

SAFEGUARD CONTROL’S

SUBBASE AND GROUNDED WHERE THE EXPOSED WIRES BEGIN.

I

I

JUNCTION BOX

A

1 BROWN WIRE AND 1 WHITE WIRE FROM THE

C7015A;

CONNECT

lNSlDE

JUNCTlON

Box;

COLOR NOT IMPORTANT; LEADWIRES

FROM JUNCTION BOX NEED NOT BE PHASED OR POLARIZED.

APPLY CAUTION STICKER, FORM NO.

96-610

SUPPLIED WITH

Ci’O15A.

TO THIS JUNCTION BOX. BOX MUST BE GROUNDED.

USE RIGID CONDUIT. OR SUPPORT FLEXIBLE CONDUIT TO

.MINIMIZE

MOVEMENT.

CONDUIT MUST BE RUN TO FLAME SAFEGUARD CONTROL’S

SUBBASE AND GROUNDED THERE. KEEP EXPOSED WIRES AS

SHORT AS POSSIBLE AND TWIST THEM.

IA3046

Adjustments and Checkout

IMPORTANT:

Before

welding the sight pipe in its

final

amplifEr

should blink at

the

same rate that the flame is

location,

complete

the

AdjustmentsandCheckout

Tests

flickering (may be as high as 20 times a second). If the lamp

below and any tests required by the burner

man@ac-

is ON (bright) continuously or not blinking while measuring

turer.

the flame current, replace the amplifier.

ADJUST DETECTOR SIGHTING POSITION

For

initial burner lightoff, consult the burner manufacturer

instructions or flame

safeguatd

control instructions.

Refer to Table 6 for the minimum acceptable flame

currents for the amplifiers and associated flame safeguard

controls.

With the flame detector installed and the burner running,

adjust the sighting position of the detector

for

optimum flame

signal.

The

R7748B

AMRLI-CHECKTM

;

R7848A

and

R7848B

(AMPLI-CHECKTM)amplifiersusedwiththeBCS7700and

7800 SERIES flame safeguard controls respectively, have a

dc voltage flame signal output.

Most existing Honeywell flame safeguard controls have a

flamecurrentjackonthecontrolplug-inflameamplifier.The

flame signal (current) can be measured

with

a volt-ohmmeter

such as the Honeywell W 136A with a zero to 25 microampdc

scale. To measure the flame current (signal), a Cable Connec-

tor (part number

1%146,

included with

W136A)

must be

used with the meter. With the

W136A

(or equivalent) posi-

tioned to the zero to 25

microamp

scale, make connections

from the meter probes to the two ends of the cable connector

plug, red to

ted,

black to black The plug end of the connector

pluginsertsdirectlyintotheamplifierflamejack(seeFig. 12).

If

the

flame safeguard control is using a

R7248B

AMRLI-

CHECP

amplifier, the red flame-indicating lamp on the

To measure flame signal voltages when using a

R7748B

amplifier, a 20,000 ohm/voltmeter with a zero to 5 or 10 Vdc

scale is suggested To measure the flame signal voltage when

using

R7848A,B

amplifiers, a volt-ohm meter with a mini-

mum sensitivity of one

megohm/volt

is recommended. The

flame signal (voltage) measurements are made as shown in

Figs. 13 and 14. The positive (red) meter lead is

connected to

the

positive (+) control jack and the negative (black) meter

lead to the negative

(-)

control jack (Corn jack with 7800

SERIES controls). If the BCS 7700 and

7800

SERIES

controls have the Keyboard Display Module, a zero to five

Vdc voltage is displayed on the module. Refer to Table 6 for

minimum and maximum flame voltages for the amplifiers