11 D04-991-2400 5/1/04

D/G-04 Service (Fluid End)

NOTE: The number in parentheses are the Reference

numbers on the illustration at right and in the Parts Manual.

This section explains how to disassemble and inspect all easily

serviceable parts of the pump. Repair procedures for the

hydraulic end (oil reservoir) of the pump are included in a later

section of the manual.

CAUTION: Do not disassemble the hydraulic end unless you

are a skilled mechanic. For assistance, contact Wanner

Engineering (TEL 612-332-5681 or FAX 612-332-6937) or the

distributor in your area.

CAUTION: The two capscrews (16) that screw through the

diaphragm plate in the pump housing hold the diaphragm plate

over the hydraulic end of the pump. Do not remove them except

when repairing the hydraulic end.

Tools and Supplies

• Straightedge (at least 6 in. long)

• Grease or petroleum jelly

• Torque wrench, rated to at least 50 ft-lbs (70 N-m)

• Emery cloth

• 1/2-in. drive socket wrench

• 5/16-in. (8-mm) open-end wrench

• 5-mm hex Allen wrench

• 8-mm hex bit socket (1/2 inch drive)

• Wanner D-04/G-04 Tool Kit, which includes the following:

• Seat puller

• Plunger holder

• Plunger guide lifter

• Shaft rotator

Service Procedures

1. Remove Manifold (3) and Valve

Plate (12)

a. Remove all eight capscrews (1) around the manifold.

Use an 8-mm hex Allen wrench.

b. Remove the manifold (3).

c. Inspect the manifold for warping or wear around the inlet

and outlet ports. If wear is excessive, replace the

manifold.

To check if the manifold is warped, place a straightedge

across it. A warped manifold should be replaced.

d. Remove the two socket-head capscrews (14) that hold

the valve plate to the pump housing. Use a 5-mm hex

Allen wrench.

e. Inspect the valve plate in the same manner as the

manifold, for excessive wear and/or warping. Replace if

necessary.

2. Inspect Valves (5-11)

The three inlet and three outlet valve assemblies are identical

(but face in opposite directions). Inspect each valve as

follows:

a. Check the spring retainer (10), and replace if worn.

b. Check the valve spring (8). If shorter than a new spring,

replace it (do not stretch a used spring).

c. Check the valve (7). If worn excessively, replace it.

d. Remove the valve seat (6), O-ring (5), and dampening

washer (11) (See note below). A seat puller is included

in the Wanner Tool Kit. Inspect all parts for wear. In all

instances, O-ring (5) should be replaced. Replace the

valve seat and/or dampening washer if necessary.

NOTE: On newer pump models, the dampening

washer (11) is not used because the valve seat (6) is

thicker. When replacing the valve seat on an older

pump model which has dampening washers, do

not

reinstall the dampening washers as the new valve

seat is thicker than the original.

e. Reinstall the valve assemblies:

• Clean the valve ports and shoulders with emery cloth,

and lubricate them with lubricating gel or petroleum jelly.

• Install the O-ring (5) on the valve seat (6).

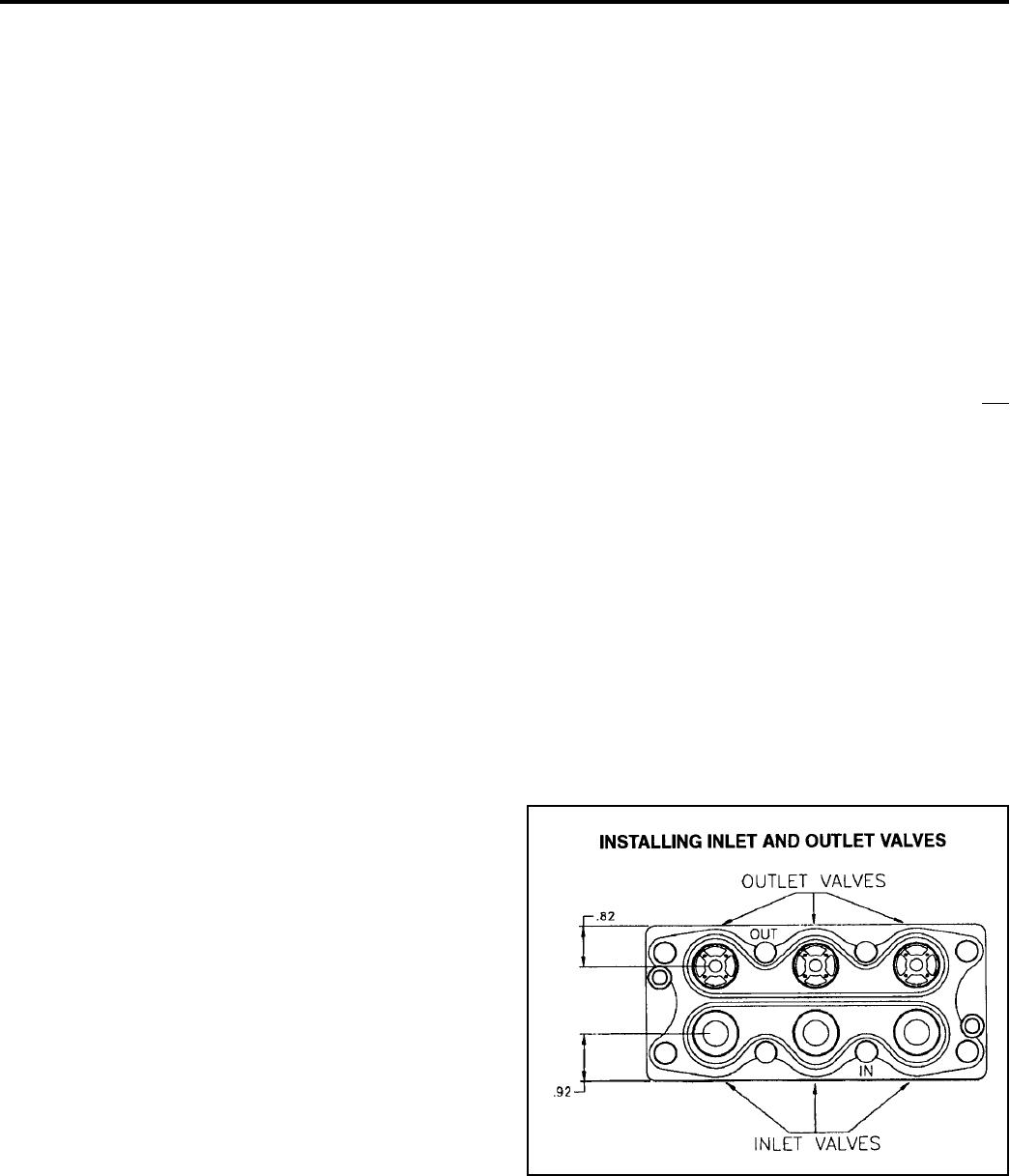

• Inlet (3 lower valves in the illustration below). Insert

the spring retainer (10) into the valve plate, then insert

the spring, valve, Tetra seal, valve seat, and dampening

washer (8,7,9,6,11). A flat O-ring (Tetra seal, 9) goes

between the retainer and seat.

• Outlet (3 upper valves in the illustration below).

Insert the dampening washer, valve seat, Tetra seal,

valve, and spring, then the retainer. Install the flat O-ring

(Tetra seal, 9) between the retainer and seat.