Page 18 Installer’s Information Manual

SECTION 9. INSTALLING DUCT

SYSTEM

Properly size duct system based on heat loss and heat gain

calculations to ensure good heating and cooling

installations, potentially fewer call-backs, and delivery of

required circulating air. Install duct system to meet current

Standard for Installations of Warm Air Heating and Air

Systems ASHRAE/NFPA 90 and local codes.

CAUTION: Failure to follow these standards could reduce

airflow or increase air leakage, resulting in reduced system

performance or furnace damage.

Design duct system so furnace will operate at a static

pressure of 0.50 inches W.C. or less. This static pressure

limitation includes the total pressure losses on both supply

air side and return air side of system. Supply side pressure

loss includes cooling coil, ducts and room registers. Return

side pressure loss includes return grilles and ducts.

Pressure losses are calculated based on 400 CFM per ton

of cooling.

SUPPLY AIR DUCT WORK

Supply air duct (plenum) connections must be at least as

big as furnace supply opening. Seal supply-air ductwork to

furnace casing, walls, ceilings or floors it passes through.

End ductwork outside furnace space.

On furnaces not equipped with a cooling coil, a removable

access panel that is large enough to allow viewing of the

heat exchanger should be provided in the supply duct. The

access panel should be accessible when the furnace is

installed. Seal access-panel cover to prevent leaks.

RETURN AIR DUCT WORK

When furnace is installed so that supply air ducts carry air

to areas outside the space containing the furnace, return air

must be handled by a duct(s) sealed to furnace casing and

terminating outside the space containing furnace.

WARNING: Failure to seal return-air ductwork

could allow combustion products to enter circulating air

stream resulting in injury or death by asphyxiation.

Air delivery above 1800 CFM requires that both sides of

furnace be used for return air, or a combination of one side

and bottom or bottom only.

If bottom return air is not used, you must attach a solid

bottom-closure panel to bottom return-air opening. Bottom

closure panel is available from manufacturer. See Table 5

for bottom closure part numbers.

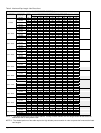

Table 5. Bottom Closure Part Numbers.

GAS

INPUT*

(Btu/hr)

MOTOR*

HORSE-

POWER

BOTTOM CLOSURE

PART NUMBER

54,000 1/3 4045901

72,000

90,000

1/2

4045901

72,000

90,000

3/4 4045902

108,000

126,000

3/4 4045903

* GAS INPUT and MOTOR HP can be found on furnace

rating plate.

WARNING: Failure to install bottom closure panel

could allow combustion products to enter circulating air

stream, resulting in injury or death by asphyxiation.

DUCT DAMPERS

You may balance airflow with dampers installed in each

branch run duct and adjust for even temperature throughout

the heated space. For proper furnace operation, make sure

of the following:

?? Supply air registers and return air grilles are open;

?? Rugs, carpets, drapes or furniture are clear of registers

and grilles;

?? Size and shape of supply air plenum is correct;

?? Number of supply air ducts is correct.

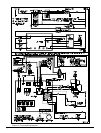

LOCATION OF COOLING COIL

If furnace will share common duct system with a separate

cooling unit, install furnace parallel to or upstream of

cooling unit. This avoids condensation in heating element.

Do not install cooling coil in return-air ductwork. With

parallel flow, dampers must be installed to prevent chilled

air from entering furnace. If dampers are not in full heat or

full cool position, furnace or cooling unit must not operate.

SECTION 10. SELECTING AND

INSTALLING FILTER CABINETS

Properly installed air filters keep blower motor, blower

wheel and cooling coil (if installed) clean. Filters and filter

cabinets are not supplied with this furnace. Filters and filter

cabinets must be field supplied or obtained from the

manufacturer. The manufacturer has bottom and side filter

cabinets available. This furnace was designed for an

external filter(s). Do not install air filters inside furnace

casing. Obtain and install proper filter frames and correctly

sized filters. To inspect, clean or replace air filters, follow

the instructions in the User’s Information Manual.

CAUTION: You must install air filters to keep blower motor,

blower wheel and cooling coil (if installed) clean. Dirty

equipment may reduce system efficiency or cause erratic

control performance and can result in damage to blower

motor, heat exchanger or air conditioner (if installed).