8

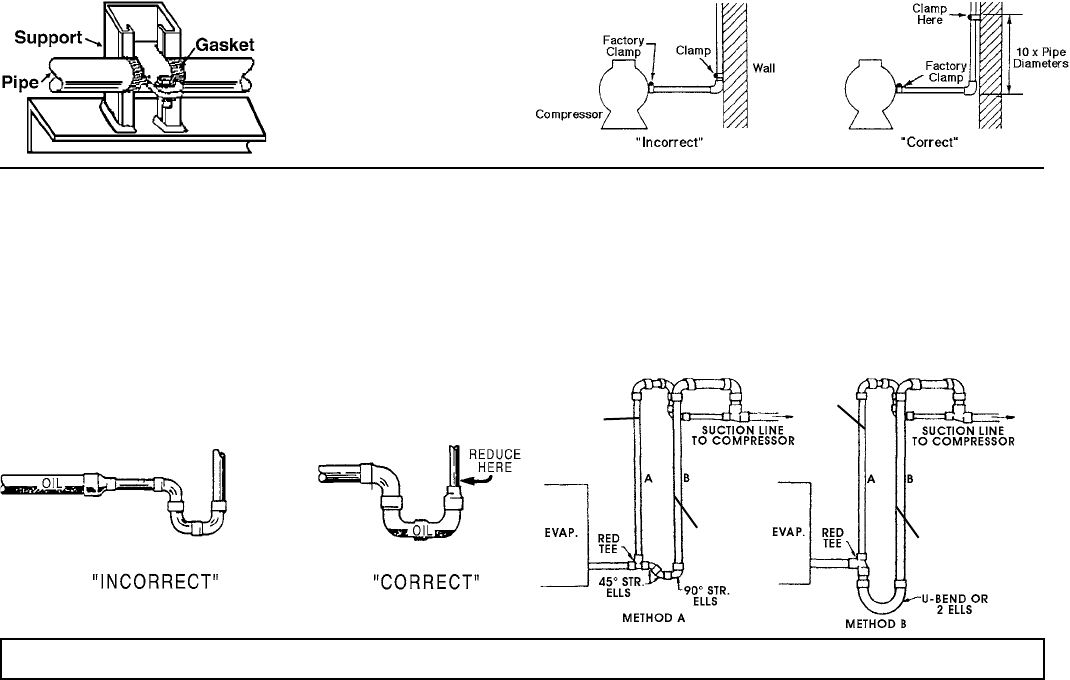

Figure 9. Example of Pipe Support Figure 10. Condensing Unit / Compressor to Wall Support

Suction Lines

Horizontal suction lines should slope away from the evaporator toward

the compressor at the rate of 1/4 inch per 10 feet for good oil return. When

multiple evaporators are connected in series using a common suction line,

the branch suction lines must enter the top of the common suction line.

For dual or multiple evaporator systems, the branch lines to each evaporator

should be sized for the evaporator capacity. The main common line should

be sized for the total system capacity.

Suction lines that are outside of refrigerated space must be insulated. See

the Line Insulation section on page 14 for more information.

Phase Loss Monitor

The combination phase sequence and loss monitor relay protects the system

against phase loss (single phasing), phase reversal (improper sequence) and

low voltage (brownout). When phase sequence is correct and full line voltage

is present on all three phases, the relay is energized as the normal condition

indicator light glows.

Note: If compressor fails to operate and the normal condition indicator light

on the phase monitor does not glow, then the supplied electrical current

is not in phase with the monitor. This problem is easily corrected by the

following steps:

Turn power o at disconnect switch.

Swap any two of the three power input wires.

Turn power on. Indicator light should glow and compressor

should start.

Observe motors for correct rotation.

Recommended Refrigerant Piping Practices

The system as supplied by Heatcraft Refrigeration Products, was

thoroughly cleaned and dehydrated at the factory. Foreign matter may enter

the system by way of the evaporator to condensing unit piping. Therefore,

care must be used during installation of the piping to prevent entrance of

foreign matter.

Install all refrigeration system components in accordance with applicable

local and national codes and in conformance with good practice required for

the proper operation of the system.

The refrigerant pipe size should be selected from the Line Sizing Tables. The

interconnecting pipe size is not necessarily the same size as the stub-out on

the condensing unit or the evaporator.

The following procedures should be followed:

Do not leave dehydrated compressors or lter-driers on

condensing units open to the atmosphere any longer than is

absolutely necessary.

Use only refrigeration grade copper tubing, properly sealed

against contamination.

Suction lines should slope 1/4" per 10 feet towards

the compressor.

1.

2.

3.

4.

a)

b)

c)

Suitable P-type oil traps should be located at the base of each

suction riser to enhance oil return to the compressor.

For desired method of superheat measurement, a pressure tap

should be installed in each evaporator suction line in

the proximity of the expansion valve bulb.

When brazing refrigerant lines, an inert gas should be passed

through the line at low pressure to prevent scaling and

oxidation inside the tubing. Dry nitrogen is preferred.

Use only a suitable silver solder alloy on suction and liquid lines.

Limit the soldering paste or ux to the minimum required to

prevent contamination of the solder joint internally. Flux only the

male portion of the connection, never the female. After brazing,

remove excess ux.

See Table 6 for discharge and liquid drain line sizes for remote

condenser connections.

If isolation valves are installed at the evaporator, full port ball

valves should be used.

Refrigerant Pipe Support

Normally, any straight run of tubing must be supported in at least two

locations near each end of the run. Long runs require additional

supports. The refrigerant lines should be supported and fastened

properly. As a guide, 3/8 to 7/8 should be supported every 5 feet; 1-1/8

and 1-3/8 every 7 feet; and 1-5/8 and 2-1/8 every 9 to 10 feet.

When changing directions in a run of tubing, no corner should be left

unsupported. Supports should be placed a maximum of 2 feet in each

direction from the corner.

Piping attached to a vibrating object (such as a compressor or

compressor base) must be supported in such a manner that will not

restrict the movement of the vibrating object. Rigid mounting will

fatigue the copper tubing.

Do not use short radius ells. Short radius elbows have points of excessive

stress concentration and are subject to breakage at these points.

Thoroughly inspect all piping after the equipment is in operation and

add supports wherever line vibration is signicantly greater than most

of the other piping. Extra supports are relatively inexpensive as

compared to refrigerant loss.

d)

e)

f)

g)

h)

i)

j)

1.

2.

3.

4.

5.

Figure 11. Suction P-Traps

Slope 1/4"

per 10 ft.

toward

compressor

Figure 12. Double Suction Riser Construction

Sized for

Minimum

Load

Sized

for Full

Load

Sized for

Minimum

Load

Sized

for Full

Load

Suction Line Risers

Prefabricated wrought copper traps are available, or a trap can be made

by using two street ells and one regular ell. The suction trap must be the

same size as the suction line. For long vertical risers, additional traps may

be necessary. Generally, one trap is recommended for each length of pipe

(approximately 20 feet) to insure proper oil movement. See Figure 11 for

methods of constructing proper suction line P-traps.

NOTE:

A suction line trap must be installed at the point where piping changes the direction of refrigerant ow from any horizontal run to an upward vertical run.