6

CAUTION:

Under no circumstance should all condenser motors be allowed to cycle o on one control. At least one motor shall be wired to operate at all times.

Under most circumstances, the condenser motor nearest the inlet header should remain on whenever the compressor is operating.

CAUTION:

Fans closest to the headers should not be cycled on standard temperature or pressure controls. Dramatic temperature and pressure changes at the

headers as a result of fan action can result in possible tube failure. Fan motors are designed for continuous duty operation.

Fan cycling controls should be adjusted to maintain a minimum of (5) minutes on and (5) minutes o. Short cycling of fans may result in a

premature failure of motor and/or fan blade.

Compressors operating below +10°F SST must have air owing over the compressor at all times when the compressor is running.

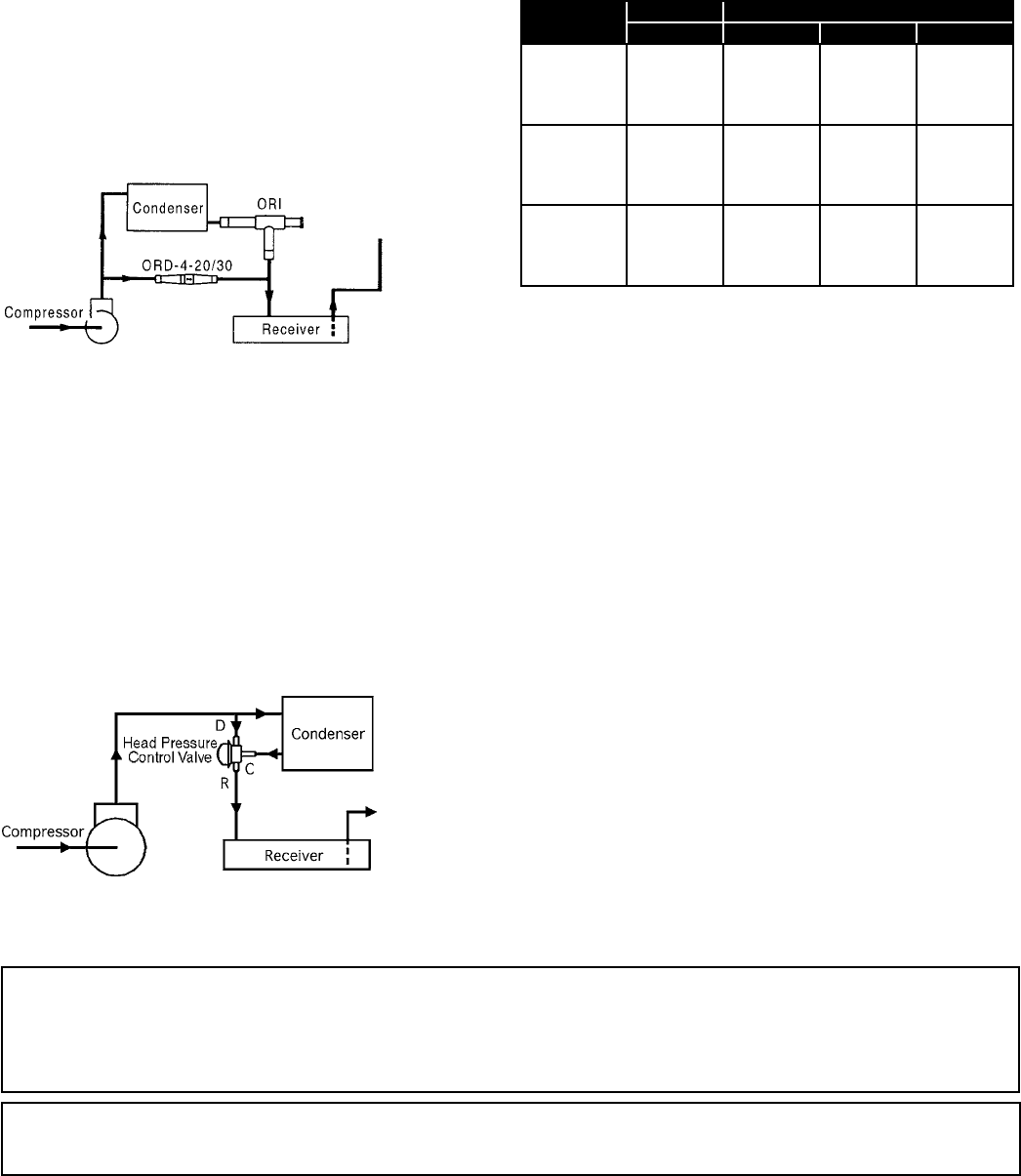

Figure 6. Dual Valve Piping Arrangement

Figure 7. Single Valve Flooding Valve Piping Arrangement

Head Pressure Control

Several types of head pressure control systems are available on

condensing units:

Dual Valve System. (See section on operation and adjustment.)

Single Valve system. No adjustments are necessary.

(See section on operation.)

Ambient Fan Cycle Control. (See section on operation

and adjustment.)

A. Dual Valve System

The system employs an ORI (open on rise of inlet pressure) valve and an ORD

( open on rise of dierential pressure) valve. The high pressure discharge gas

is introduced above the liquid in the receiver tank. The receiver discharge is

regulated by the ORI valve.

The discharge pressure of the ORI valve must be adjusted to regulate the unit

for proper operating conditions. Adjust the ORI valve shown on the following

diagram to maintain a discharge pressure of 160 to 180 PSIG.

A.

B.

C.

Table 1. Ambient Fan Cycle Thermostat Settings

Models

Design Thermostat Settings

T.D. T1 T2 T3

30 60

2-fan units: 25 65

20 70

4-fan units: 15 75

30 60 40

3-fan units: 25 65 55

20 70 60

6-fan units: 15 75 65

30 60 50 30

8-fan units: 25 65 55 40

20 70 65 50

15 75 70 60

NOTE: Cycle pairs of fans on double wide units.

Operation and Adjustment

Condensing units with dual valves require sucient charge to partially ood

the condenser during low ambient conditions.

Valve adjustment should be made with gauges connected to the discharge

port of the compressor. Adjustments should be made during mild or

low ambient conditions. Turning the valve stem “clockwise” on the ORI

valve will increase the discharge pressure, while turning the valve stem

“counterclockwise” will decrease the discharge pressure.

If adjustments are made during warm ambient conditions, it may not be

possible to adjust the regulator valve as low as desired. Readjustment may

be necessary once cooler conditions prevail.

B. Single Valve System

The standard valve used on high pressure refrigerant systems controls

the head pressure at approximately 180 PSIG. There is no adjustment for

this valve. On low pressure refrigerant systems the valve controls pressure

at approximately 100 PSIG. For energy eciency, the 100 PSIG valve is

sometimes used on high pressure refrigerant systems.

At condensing pressures above the valve setting, ow enters Port C and

leaves Port R. When the condensing pressure falls below the valve setting,

the valve modulates to permit discharge gas to enter Port D. Metering

discharge gas into the refrigerant ow leaving the condenser produces a

higher pressure at the condenser outlet, reduces the ow, and causes the

level of liquid refrigerant to rise in the condenser. This “ooding” of the

condenser with liquid refrigerant reduces the available condensing surface,

holding the condensing pressure at the valve setting.

C. Ambient Fan Cycle Control

This is an automatic winter control method which will maintain a condensing

pressure within reasonable limits by cycling fan motors in response to

outside air temperature. The thermostat(s) should be eld adjusted to shut

o the fan when the condensing temperature is reduced to approximately

90

˚

F. Table 1 lists approximate settings for several system T.D.’s. These settings

are approximate as they do not take into account variations in load.