Page 18 For technical questions, please call 1-800-444-3353. SKU 3914

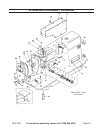

Feed Lifting

Shaft Crank (1e)

Feed Bar Body

Subassembly (4e)

Bolt (2e)

Figure 32

0.03”~0.033” ( )

0.028”~0.031” ( )

0.037”~0.041” ( )

1. Loosen the Bolt (2e) of the Feed Lifting

Shaft Crank (1e).

Move the Feed Bar Body Subassembly 2.

(4e) up or down to make the adjustment.

Tighten the Bolt (2e), being careful not to 3.

overtighten.

Adjusting Needle-to-hook Timing

Figure 33

Rubber Plug (46a)

&

Bolt (28c)

Needle Bar

(31c)

Needle

Bar

(31c)

Needle

Bar Lower

Bushing

(27c)

Hook

Blade

Point

Rotating

Hook (20c)

1. Turn the Hand Wheel (7b) to bring the

Needle Bar down to the lowest point of

its stroke.

Remove and set aside the Rubber Plug 2.

(46a). Loosen the Bolt (28c).

When using a DBX1 needle, align to 3.

marker line “A” on the Needle Bar (31c)

with the bottom end of the Needle Bar

Lower Bushing (27c), then tighten Bolt

(28c).

When using a DAX1 needle, align to

marker line “B” on the Needle Bar (31c)

with the bottom end of the Needle Bar

Lower Bushing (27c), then tighten the

Bolt (28c).

When using a DBX1 needle, loosen 4.

Rotating Hook (20c) Set Screws, turn

the Hand Wheel, and align the marker

line “B” on the Needle Bar (31c) with

the bottom end of the Needle Bar Lower

Bushing (27c).

When using a DAX1 needle, align the

marker line “D” on the Needle Bar (31c)

with the bottom end of the Needle Bar

Lower Bushing (27c).

After making the adjustments in steps 3 5.

and 4, align the Hook Blade Point on the

Rotating Hook (20c) with the center of

the Needle.

Provide a clearance of .001” to .004”

(0.04 to 0.1 mm) between the Needle

and the Hook Blade Point. This

clearance is less than 1/64” (almost

touching). Securely tighten the Set

Screws on the Rotating Hook. If the

clearance is too small, the tip of the

Hook Blade Point will be abraded. If it is

too large, it will lead to skipped stitches.

REV 10b