14 684025

Troubleshooting

Troubleshooting Techniques

Because the pumps are mechanically linked, the action of

one pump can affect the readin

g

s of the second pump.

Therefore, the key to successful troubleshooting is to be

sure to isolate the problem.

For example, if the secondary pump pressure, as read on

the

g

au

g

e, is low and slu

gg

ish durin

g

the pump

chan

g

eover. The most likely problem is a bindin

g

primary

pump. To isolate the problem:

1. Relieve the pressure.

2. With the sampling valves still open, set the air supply

regulator to the lowest setting and open the bleed-

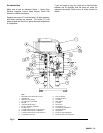

type main air valve (1). Refer to fi

g

ure 6. Increase

the re

g

ulator settin

g

until the pump just be

g

ins to

move. Notice the position of the secondary pump

(11). Turn off the bleeder-type main air valve (1) so

that the secondary pump rod is at its lowest position

when the pump stops.

8. With the main bleed-type air valve (1) off, remove

the thumb screws (14) and

g

uards (15) from each

side of the proportioner.

9. Unscrew the connectin

g

rod nut (10) from the

primary pump. Now you can verify the operation of

the secondary pump alone.

Reinstall the

g

uards (15) on both sides of the

proportioner. Turn the main air valve (1) back on

and carefully increase the air pressure.

10. Using the sampling valves at the mixer manifold:

A. Open and close the samplin

g

valves and check

for pump stallin

g

on both the up and down

strokes.

B. Check for rapid

g

au

g

e response durin

g

the

pump changeover

11. When the operation of the secondary side has been

verified, reconnect the connectin

g

rod (10) of the

primary pump.

WARNING WARNING

To reduce the risk of a serious injury, always follow the

Pressure Relief Procedure on page 11 whenever you

are instructed to relieve the pressure.

Use very low air pressure to the air motor when

troubleshootin

g

the system. This system can produce

very high fluid pressure, which can cause serious injury,

3. With the main bleed-type air valve (1) off, remove

the thumb screws (14) and

g

uards (15) from each

side of the proportioner.

4. Unscrew the connectin

g

rod nut (11) from the

secondary pump. Now you can verify the operation

of the primary pump alone.

includin

g

injection, splashin

g

in the eyes or on the skin,

and injury from moving parts.

To reduce the risk of a serious injury, always follow the

Pressure Relief Procedure on page 11 if the problem

you are checking does not require air.

Reinstall the

g

uards (15) on both sides of the

proportioner. Turn the main air valve (1) back on

and carefully increase the air pressure.

5. Using the sampling valves at the mixer manifold:

WARNING

A. Open and close the samplin

g

valves and check

for pump stallin

g

on both the up and down

strokes.

B. Check for rapid

g

au

g

e response durin

g

the

pump changeover

To reduce the risk of injurin

g

or amputatin

g

your hands,

fin

g

ers, or other body parts, never place your hands,

body or tools inside the safety panels for any reason

while the unit is operating.

6. When the operation of the primary side has been

verified, reconnect the connectin

g

rod (11) of the

secondary.

7. With the sampling valves still open, set the air supply

regulator to the lowest setting and open the bleed-

type main air valve (1). Increase the regulator setting

until the pump just be

g

ins to move. Notice the

position of the primary pump. Turn off the bleeder-

type main air valve (1) so that the primary pump rod

(10) is at its lowest position when the pump stops.