12 684025

Checking the Ratio

Note: The mix ratio must be checked at the normal

operatin

g

fluid pressure of the pump. Most mixer

manifolds provide a means for checkin

g

mix ratio

that includes needle valves for adjustin

g

the fluid

pressure during the test. The following procedure is

an example of how to properly check the mix ratio.

1. Open the mixer manifold and trigger your spray gun.

2. Set your operatin

g

pressure. After determinin

g

the

operatin

g

pressure, release the spray

g

un tri

gg

er and

engage the safety latch.

3. Close the mixer manifold inlet valves.

4. Sli

g

htly open the samplin

g

valve on the secondary

pump side. Sli

g

htly open the samplin

g

valve on the

primary pump side. This will prevent pressure from

buildin

g

up on the secondary pump, causin

g

the relief

valve to open.

5. Place a

g

rounded waste container under the samplin

g

valve.

6. Open the mixer manifold. Use the sampling valves to

adjust the pressures to your

normal operatin

g

pressures.

7. Close the mixer manifold. Put the samplin

g

containers under the sampling valves.

8. Open the mixer manifold. Check the ratio; make sure

the pressure is within 20% of your normal operatin

g

pressure. Close the mixer manifold when enou

g

h

fluid has been dispensed into the samplin

g

containers.

NOTE: If the pressure readings are not within 20% of

your normal operatin

g

pressure, follow the

flushin

g

procedure on pa

g

e 11, then take a

sample a

g

ain. If your sample ratio is incorrect,

there is a problem with the sampling valves, ratio

settin

g

, or pump operation. Check the ratio

setting or service the sampling valves or pump.

Maintenance

Pump Lubrication

Wet Cups

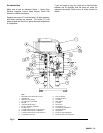

Each of the fluid cylinders has a wet cup (18) at the top

that must be kept lubricated. See figure 6. The wet cups

should be inspected and filled on a weekly basis, or

more frequently if found to be dry. To inspect the wet

cups, follow the pressure relief procedure on page 11.

Bearings

Many of the bearin

g

surfaces on the proportioner are

permanently lubricated or are self lubricating. There are

four main bearings (21) on the lever arm

that must be

lubricated

on a regular interval. The lubrication interval

is every six months in single shift operation. To lubricate

the bearin

g

s, follow the pressure relief procedure on

page 11.

WARNING WARNING

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the Pressure

Relief Procedure on page 11.

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the Pressure

Relief Procedure on page 11.

With the bleeder type main air valve (1) turned off,

remove the thumb screws (14) and the two guards (15)

from the sides of the proportioner. The wet cups (18)

should be filled to 1/3 full with Graco Throat Seal Liquid

(TSL) or compatible solvent.

The packing nuts (19) are torqued at the factory and are

ready for operation. If one becomes loose and there is

leaking from the throat packings, relieve the pressure,

then torque the nut to 136–149 N.m (100–110 ft-lb)

usin

g

the supplied wrench (20). Do this whenever

necessary. Do not over tighten the packing nut.

With the bleeder type main air valve turned off, remove

the twenty hex bolts (16) with a 13mm wrench or socket

and then remove the four sheet metal covers (17) from

the front and back of the proportioner.

The left rear cover may contain a sensor attached to a

cable. Do not remove the sensor, but carefully set the

cover to the side without strainin

g

or dama

g

in

g

the

sensor or cable. The four main bearin

g

s (21) are now

exposed. Use the adapter (205532) provided to grease all

four bearin

g

s. One or two squirts (2-3 cc) will be

sufficient.