308550 21

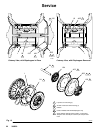

Reassembly – Overmolded Diaphragms

WARNING

To reduce the risk of serious injury, including

amputation, do not put your fingers or hand be-

tween the air cover and the diaphragm.

1. Lubricate and install the shaft u–cup packings

(402*) so the lips face out of the housing (1). See

Fig. 13.

2. Assemble the air side plate (104) onto the dia-

phragm (403). The wide, radiused side of the plate

must face the diaphragm. Apply medium–strength

(blue) Loctite or equivalent to the threads of the

diaphragm assembly. Screw the assembly into the

shaft (24) hand–tight.

3. Grease the length and ends of the diaphragm shaft

(24). Insert the shaft/diaphragm assembly into one

side of the pump. Align the fluid cover (101) and

the center housing (1) so the arrow (A) faces the

same direction as the air valve. Secure the cover

with the screws (107 and 108), handtight.

4. Torque the longer screws (108) oppositely and

evenly to 190–220 in–lb (21–25 NSm), using a

13mm socket wrench. Then torque the shorter

screws (107). See Torque Sequence, page 32.

5. Assemble the other diaphragm assembly to the

shaft as explained in step 2. This diaphragm will

be lifted off the air cover at this point.

6. Supply the pump with low pressure air (less than 7

psi [0.05 MPa, 0.5 bar]). The diaphragm will very

slowly pull onto the air cover. Find the pressure

that keeps the diaphragm close enough to secure

with the screws, but does not let it contact the pilot

pin.

NOTE: Do not deform the diaphragm manually. The

diaphragm needs uniform pressure to deform properly

for maximum life.

7. Align the fluid cover (101) and the center housing

(1) so the arrow (A) faces the same direction as

the air valve. Secure the cover with two of the

longer screws (108), handtight.

NOTE: If the diaphragm contacts the pilot pin and is

forced away from the air cover, try Step 5 again. If

necessary, return to Step 3.

8. Torque the longer screws (108) oppositely and

evenly to 190–220 in–lb (21–25 NSm), using a

13mm socket wrench. Then torque the shorter

screws (107). See Torque Sequence, page 32.

9. Reassemble the ball check valves and manifolds

as explained on page 18.