20 308550

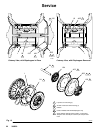

Service

4. Unscrew one outer plate (105) from the diaphragm

shaft (24). Remove one diaphragm (401), and the

inner plate (104). See Fig. 13.

For overmolded diaphragms: Grip both dia-

phragms securely around the outer edge and

rotate counterclockwise. One diaphragm assembly

will come free and the other will remain attached to

the shaft. Remove the freed diaphragm and air

side plate.

NOTE: PTFE models include a PTFE diaphragm (403)

in addition to the backup diaphragm (401).

5. Pull the other diaphragm assembly and the dia-

phragm shaft (24) out of the center housing (1).

Hold the shaft flats with a 19 mm open–end

wrench, and remove the outer plate (105) from the

shaft. Disassemble the remaining diaphragm

assembly.

For overmolded diaphragms: Pull the other dia-

phragm assembly and the diaphragm shaft (24)

out of the center housing (1). Hold the shaft flats

with a 19 mm open–end wrench and remove the

diaphragm and air side plate from the shaft.

6. Inspect the diaphragm shaft (24) for wear or

scratches. If it is damaged, inspect the bearings

(19) in place. If the bearings are damaged, refer to

page 23.

7. Reach into the center housing (1) with an o-ring

pick and hook the u-cup packings (402), then pull

them out of the housing. This can be done with the

bearings (19) in place.

8. Clean all parts and inspect for wear or damage.

Replace parts as needed.

Reassembly – Standard Diaphragms

1. Grease the shaft u-cup packings (402*) and install

them so the lips face out of the housing (1). See

Fig. 13.

2. Grease the length and ends of the diaphragm shaft

(24) and slide it through the housing (1).

3. Assemble the inner diaphragm plates (104), dia-

phragms (401*), PTFE diaphragms (403*, if pres-

ent), and outer diaphragm plates (105) exactly as

shown in Fig. 13. These parts must be assembled

correctly.

4. Apply medium-strength (blue) LoctiteR or equiva-

lent to the threads of the fluid-side plates (105).

Hold one of the outer plates (105) with a wrench,

and torque the other outer plate to 20 to 25 ft-lb

(27 to 34 NSm) at 100 rpm maximum. Do not

over-torque.

5. Align the fluid covers (101) and the center housing

(1) so the arrows (A) on the covers face the same

direction as the air valve (B). Secure the covers

with the screws (107 and 108), handtight. Install

the longer screws (108) in the top and bottom

holes of the covers. See Fig. 12.

6. First, torque the longer screws (108) oppositely

and evenly to 190–220 in-lb (21–25 NSm), using a

13 mm socket wrench. Then torque the shorter

screws (107). See Torque Sequence, page 32.

7. Reassemble the ball check valves and manifolds

as explained on page 18.