5

GROUND LEVEL INSTALLATIONS ONLY:

• When the unit is installed on the ground adjacent to

the building, a level concrete (or equal) base is

recommended. Prepare a base that is 3” larger than

the package unit footprint and a minimum of 3” thick.

• The base should also be located where no runoff of

water from higher ground can collect in the unit.

ROOF TOP INSTALLATIONS ONLY:

• To avoid possible property damage or personal injury,

the roof must have sufficient structural strength to carry

the weight of the unit(s) and snow or water loads as

required by local codes. Consult a structural engineer

to determine the weight capabilities of the roof.

• The unit may be installed directly on wood floors or

on Class A, Class B, or Class C roof covering material.

• To avoid possible personal injury, a safe, flat surface

for service personnel should be provided.

• As indicated on the unit data plate, a minimum

clearance of 36” to any combustible material is

required on the furnace access side of the unit. All

combustible materials must be kept out of this area.

• This 36” clearance must also be maintained to insure

proper combustion air and flue gas flow. The

combustion air intake and furnace flue discharge must

not be blocked for any reason, including blockage by

snow.

• Adequate clearances from the furnace flue discharge

to any adjacent public walkways, adjacent buildings,

building openings or openable windows must be

maintained in accordance with the latest edition of

the National Fuel Gas Code (ANSI Z223.1)

• Minimum horizontal clearance of 48” from the furnace

flue discharge to any electric meters, gas meters,

regulators and relief equipment is required.

UNIT PRECAUTIONS

• Do not stand or walk on the unit.

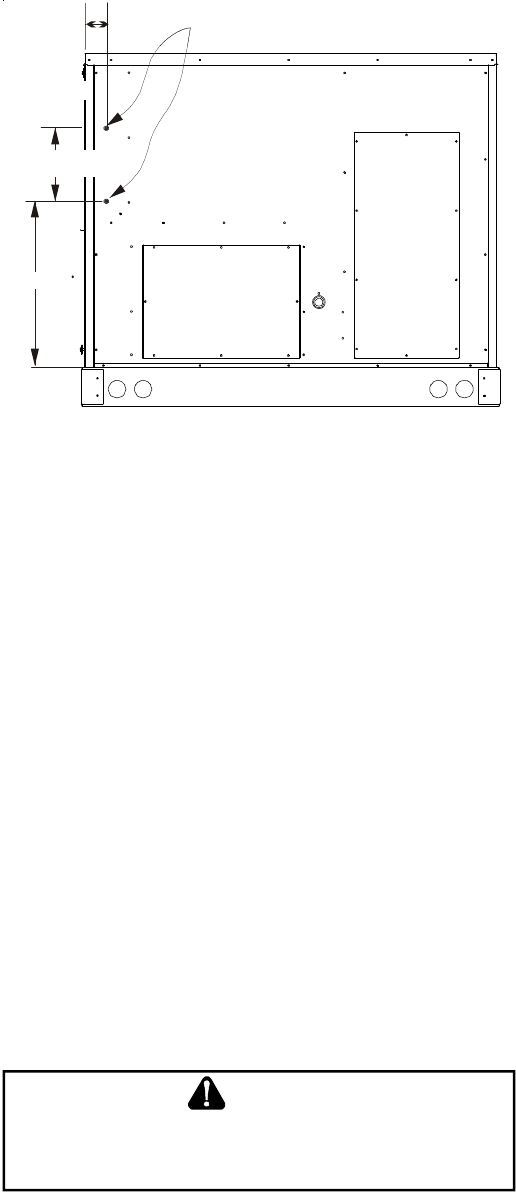

• Except for holes in the wiring entrances (see Figure

below), do not drill holes anywhere in panels or in

the base frame of the unit. Unit access panels

provide structural support.

LOW VOLTAGE ENTRANCE

DIMPLES MARK DRILL LOCATIONS

HIGH VOLTAGE ENTRANCE

10 3/16”

3 3/4”

26 ½”

ELECTRICAL ENTRANCE LOCATIONS

• Do not remove any access panels until unit has been

installed on roof curb or field supplied structure.

• Do not roll unit across finished roof without prior

approval of owner or architect.

• Do not skid or slide on any surface as this may

damage unit base. The unit must be stored on a

flat, level surface. Protect the condenser coil

because it is easily damaged.

ROOF CURB INSTALLATIONS ONLY:

Curb installations must comply with local codes and should

be done in accordance with the established guidelines of the

National Roofing Contractors Association.

Proper unit installation requires that the roof curb be firmly

and permanently attached to the roof structure. Check for

adequate fastening method prior to setting the unit on the

curb.

Full perimeter roof curbs are available from the factory and

are shipped unassembled. Field assembly, squaring, level-

ing and mounting on the roof structure are the responsibility

of the installing contractor. All required hardware necessary

for the assembly of the sheet metal curb is included in the

curb accessory.

T

O

PREVENT

POSSIBLE

EQUIPMENT

DAMAGE

,

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

,

THE

FOLLOWING

BULLET

POINTS

MUST

BE

OBSERVED

WHEN

INSTA LLING

THE

UNIT

.

WARNING

• Sufficient structural support must be determined prior

to locating and mounting the curb and package unit.

• Ductwork must be constructed using industry

guidelines. The duct work must be placed into the

roof curb before mounting the package unit. Our full

perimeter curbs include duct connection frames to be

assembled with the curb. Cantilevered type curbs

are not available from the factory.