10

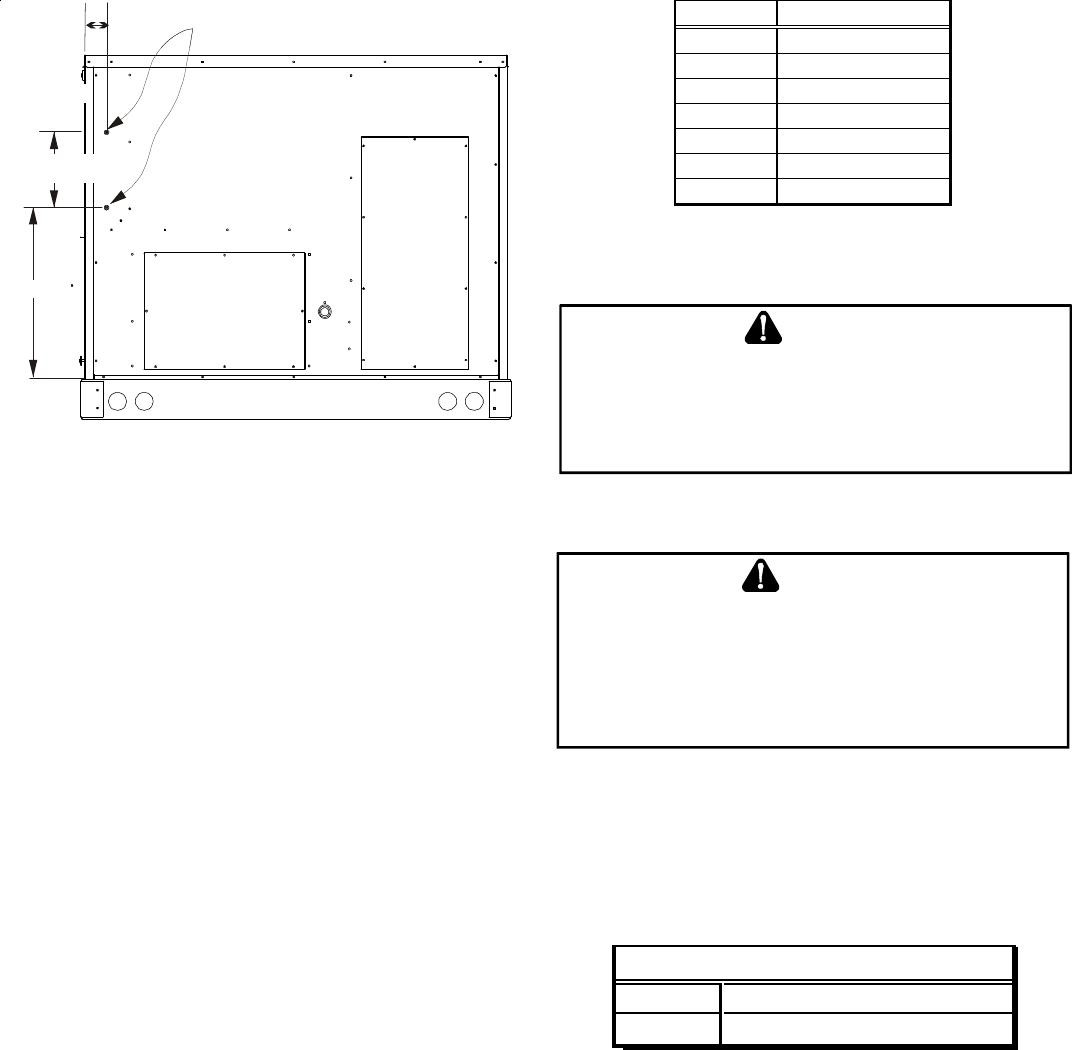

LOW VOLTAGE ENTRANCE

DIMPLES MARK DRILL LOCATIONS

HIGH VOLTAGE ENTRANCE

10 3/16”

3 3/4”

26 ½”

ELECTRICAL ENTRANCE LOCATIONS

Unit is equipped with a Low Voltage Terminal Block and has

Single Point wiring to the contactor.

LOW VOLTAGE CONTROL WIRING

1. A 24V thermostat must be installed for unit operation.

It may be purchased with the unit or field -supplied.

Thermostats may be programmable or

electromechanical as required.

2. Locate thermostat or remote sensor in the conditioned

space where it will sense average temperature. Do

not locate the device where it may be directly exposed

to supply air, sunlight or other sources of heat. Follow

installation instructions packaged with the thermostat.

3. Use #18 AWG wire for 24V control wiring runs not

exceeding 75 feet. Use #16 AWG wire for 24V control

wiring runs not exceeding 125 feet. Use #14 AWG

wire for 24V control wiring runs not exceeding 200

feet. Low voltage wiring may be National Electrical

Code (NEC) Class 2 where permitted by local codes.

4. Route thermostat wires from sub-base terminals to

the unit. Control wiring should enter through the duct

panel (dimple marks entrance location). Connect

thermostat and any accessory wiring to low voltage

terminal block TB1 in the main control box.

NOTE: Field-supplied conduit may need to be installed

depending on unit/curb configuration. Use #18 AWG solid

conductor wire whenever connecting thermostat wires to

terminals on sub-base. DO NOT use larger than #18 AWG

wire. A transition to #18 AWG wire may be required before

entering thermostat sub-base.

LEAD THERMOSTAT

Red R (24V)

Green G (Fan)

Yellow Y1 (High Cool)

Purple Y2 (Low Cool)

Blue Common (if req'd)

White W1 (Heat)

Brown W2 (High Heat)

CPG 090 THROUGH 300 (GAS HEAT)

GAS SUPPLY PIPING

T

O

PREVENT

PERSONAL

INJURY

OR

DEATH

DUE

TO

IMPROPER

INSTALLATION

,

ADJUSTMENT

,

ALTERATION

,

SERVICE

OR

MAINTENANCE

,

REFER

TO

THIS

MANUAL

.F

OR

ADDITIONAL

ASSISTANCE

OR

INFOR MATIO N

,

CONSULT

A

QUALIFIED

INSTALLER

,

SERVICE

AGENCY

OR

THE

GAS

SUPPLIER

.

WARNING

IMPORTANT NOTE: This unit is factory set to operate on

natural gas at the altitudes shown on the rating plate.

T

O

PREVEN T

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

WHEN

EITHER

USING

PROPANE

GAS

ALONE

OR

AT

HIGHER

ALTITUDES

,

OBTAIN

AND

INSTALL

THE

PROPER

CONVERSION

KIT

(

S

).F

AILURE

TO

DO

SO

CAN

RESULT

IN

UNSATISFACTORY

OPERATION

AND

/

OR

EQU IPMENT

DAMAGE

.

H

IGH

ALTITUD E

KITS

ARE

FOR

U.S.I

NSTALLATIONS

ONLY

AND

ARE

NOT

APPROVED

FOR

USE

IN

C

ANADA

.

WARNING

The rating plate is stamped with the model number, type of

gas and gas input rating. Make sure the unit is equipped to

operate on the type of gas available. Conversion to propane

(LP) gas is permitted with the use of the factory authorized

conversion kit (see the unit Technical Manual for the appro-

priate kit). For High Altitude derates, refer to the latest edition

of the National Fuel Gas Code NFPA 54/ANSI Z223.1.

NATURAL

Min. 5.0" W.C., Max. 10.0" W.C.

PROPANE

Min. 11.0" W.C., Max. 14.0" W.C.

INLET GAS PRESSURE

Inlet Gas Pressure Must Not Exceed the Maximum Value Shown in Table

Above.

The minimum supply pressure should not vary from that

shown in the table above because this could prevent the unit

from having dependable ignition. In addition, gas input to the

burners must not exceed the rated input shown on the rating

plate. Overfiring of the unit could result in premature heat

exchanger failure.

PIPING

IMPORTANT NOTE: To avoid possible unsatisfactory opera-

tion or equipment damage due to under firing of equipment,

do not undersize the natural/propane gas piping from the

meter/tank to the unit. When sizing a trunk line, include all

appliances on that line that could be operated simultaneously.