23

CLEAN OUTSIDE COIL (QUALIFIED SERVICER ONLY)

The coil with the outside air flowing over it should be inspected

annually and cleaned as frequently as necessary to keep the

finned areas free of lint, hair and debris.

CONDENSER, EVAPORATOR, AND INDUCED DRAFT MOTORS

Bearings on the air circulating blower motor, condenser mo-

tor and the combustion fan motor are permanently lubricated.

No additional oiling is required.

FLAME SENSOR (QUALIFIED SERVICER ONLY)

A drop in the flame current can be caused by a nearly invis-

ible coating on the flame sensor. This coating, created by the

fuel or combustion air supply, can be removed by carefully

cleaning the flame sensor with steel wool.

NOTE: After cleaning, the microamp signal should be stable

and in the range of 4 - 6 microamps DC.

FLUE PASSAGES (QUALIFIED SERVICER ONLY)

At the start of each heating season, inspect and, if neces-

sary, clean the unit flue passage.

LUBRICATION

The fan shaft bearings, the 1 to 2 HP supply fan motors the

condenser fan motors and compressors are permanently lu-

bricated.

INSPECTION & CLEANING

All flue product carrying areas of the furnace, its vent sys-

tem, and main burners should be examined by a qualified

service agency before the start of each heating season. This

examination is necessary for continued safe operation. Par-

ticular attention should be given to deterioration from corro-

sion or other sources. This examination is accomplished in

the following manner.

1. Disconnect power to the unit and remove furnace

section access panel.

2. Remove burner assembly:

a. Disconnect the three wires from the gas valve after

noting which wires are connected to each terminal.

b. Disconnect wires from the flame rod and ignition

electrode.

c. Disconnect the gas piping at the union.

d. The entire burner assembly can now be removed

from the unit.

NOTE: Use all screws that were removed; they are

necessary for safe and proper operation of the unit.

3. Inspect and periodically clean the vent outlet (bird

screen) on the access panel.

NOTE: Periodic observation of the flame and a log of C0

2

measurements are recommended. This will aid in determining

whether the furnace is operating efficiently or if the furnace

requires cleaning.

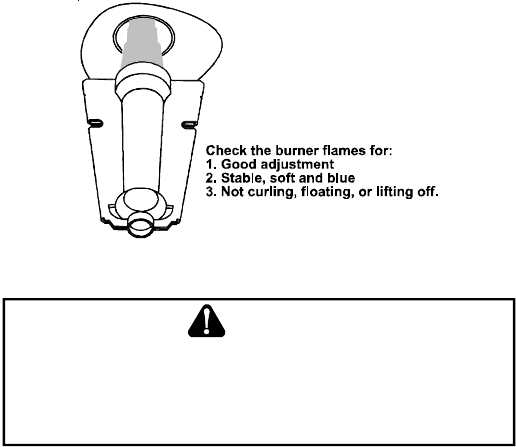

Flames should be stable, soft and blue (dust may cause or-

ange tips but must not be yellow). The flames must extend

directly outward from the burner without curling, floating or

lifting off.

BURNER FLAME

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRIC

SHOCK

,

DO

NOT

REMOVE

ANY

INTERNAL

COMPARTMENT

COVERS

OR

ATTEMPT

ANY

ADJUSTMENT

.C

ONTACT

A

QUALIFIED

SERVICER

AT

ONCE

IF

AN

ABNORM AL

FLAME

SHOULD

DEVELOP

.

WARNING

At least once a year, prior to or during the heating season,

make a visual check of the burner flames.

NOTE: This will involve removing and reinstalling the heat

exchanger door on the unit, which is held by two screws. If

you are uncertain about your ability to do this, contact a

qualified servicer.

If a strong wind is blowing, it may alter the airflow pattern

within the unit enough that an inspection of the burner flames

is not possible.

FUNCTIONAL PARTS

Refer to the unit Parts Catalog for a list of functional parts.

Parts are available from your distributor.