9

Drain Line Connection

Note:

Standard commercial practices are expressed

here. Local codes may require changes to the following

suggestions. Check with local authorities before installing

a water conditioning system.

The system should be above, and not more than 20 feet

(6.1 m) from a drain. Connect an appropriate fitting and

1/2-inch (1.3-cm) plastic tubing to the drain line

connection on the rear of the control valve.

If the backwash flow is more than 5 gpm or if the unit is

located more than 20 feet (6.1 m) from the drain, use 3/4-

inch (1.9-cm) tubing for runs up to 40 feet (12.2 m). Also,

purchase appropriate fitting to connect the 3/4-inch

tubing to the 1/2-inch NPT drain connection.

If unit is located where the drain line must be elevated, you

may elevate the line up to 5 feet (1.5 m) providing the run

does not exceed 15 feet (4.6 m) and water pressure at the

conditioners is not less than 40 psi (2.8 bar).

Where drain line is elevated but empties into a drain below

the level of the control valve, form a 7-inch (18-cm) loop at

the far end of the line so that the bottom of the loop is level

with the drain line connection. This will provide an

adequate siphon trap.Where a drain empties into an

overhead sewer line, a sink-type trap must be used. Secure

the end of the drain line to prevent it from moving

(Figure 11).

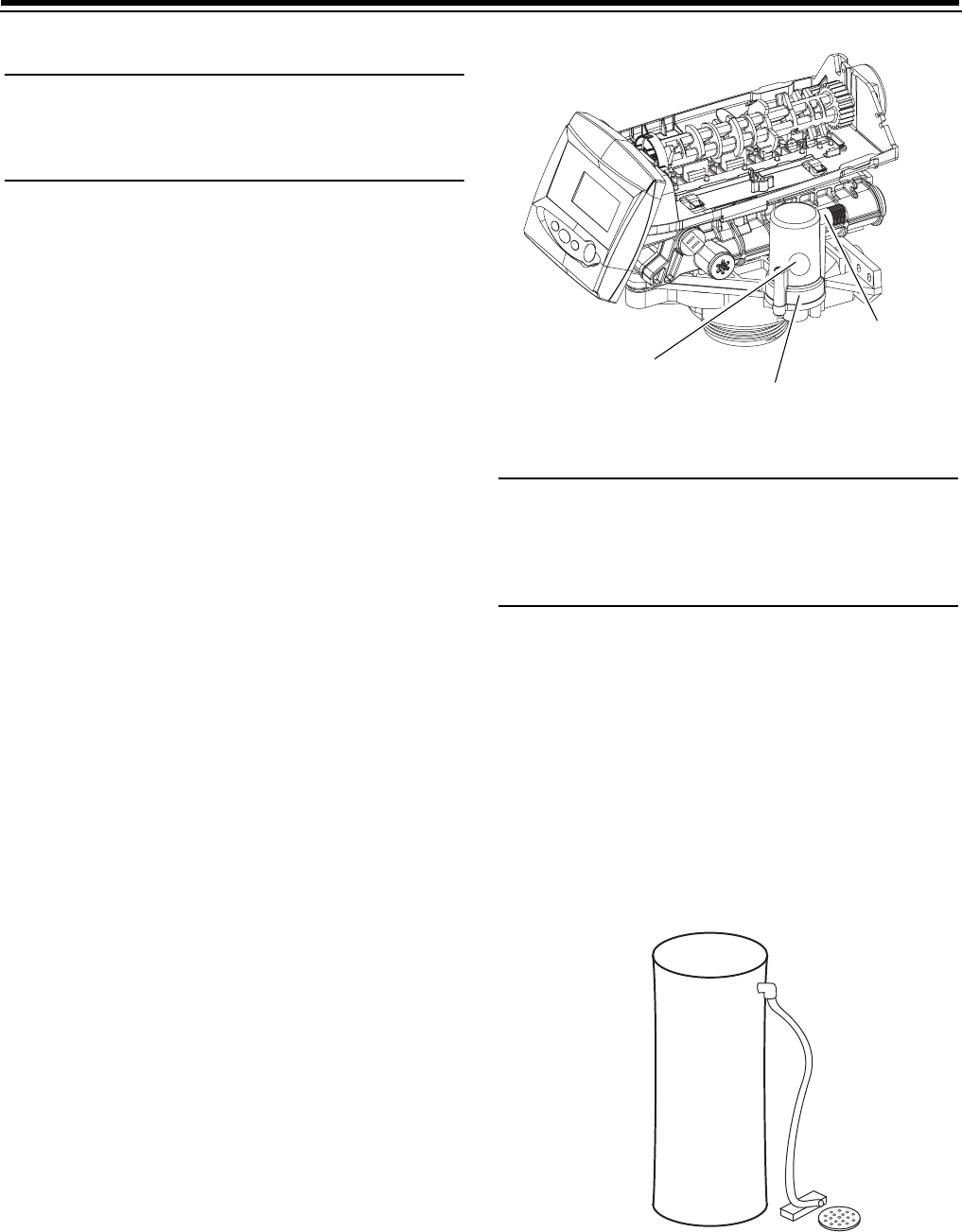

Brine Line Connection

It is recommended that separate brine lines be used for

each tank.

A regenerant tank aircheck is not required when using a

255 valve with the built-in aircheck. Doing so will cause

premature checking and may result in hard water or

regenerant tank overflow. The 255 aircheck is available

standard with a 1/4" NPT tube compression fitting. The

use of Teflon tape is required on the 1/4" NPT connection.

Install an appropriate fitting onto the 1/4-inch male NPT

connection on the air check (Figure 9), and install a length

of 3/8-inch polyethylene tubing between the air check

fitting and the brine pick-up tube at the brine tank. If you

are using a brine valve remove the ball in the air check to

avoid possible premature checking.

Figure 9

Note:

Make sure that all fittings and connections are

vacuum tight so that premature checking does not take

place. Premature checking occurs when the ball in the air

check falls to the bottom before all brine is drawn out of

the brine tank.

Brine Tank Overflow Line Connection

In the event of a malfunction, the brine tank overflow

connection directs overflow to the drain instead of spilling

it on the floor where it could cause water damage.

Complete the following steps to connect the overflow

fitting to the brine tank:

1. Locate the fitting hole on the side of the brine tank.

2. Insert the overflow fitting (not supplied) into the tank

and tighten with the plastic thumb nut and gasket as

illustrated in Figure 10.

Figure 10 Brine Tank Drain

3. Attach a length of 1/2-inch (1.3-cm) tubing (not

supplied) to the fitting and run to the drain.

Check Ball

Air Check

Regenerant Tank

Tube Connection