8

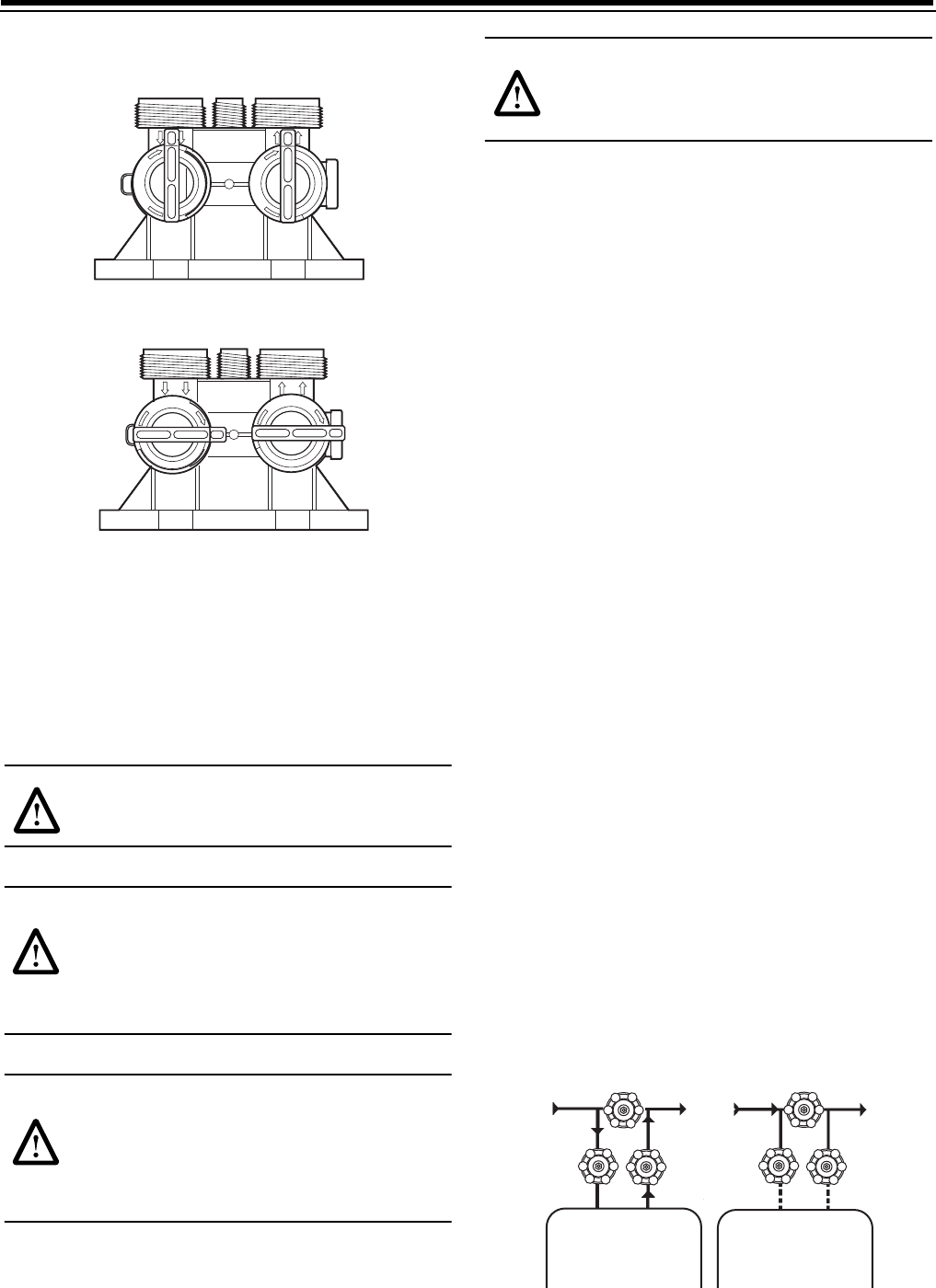

Figure 7

Installation

All plumbing must conform to local codes. The two tanks

should be plumbed to an interconnecting manifold,

Figure 6. It is highly recommended that separate brine

lines be used for each tank. It is critical for the resin, resin

volume, inlet piping, etc. to be identical for both tanks.

WARNING:

Do not use tools to tighten plastic

fittings. Over time, stress may break the

connections. Hand tighten the nuts.

WARNING:

Do not use petroleum grease on

gaskets when connecting bypass plumbing. Use

only 100% silicone grease products when

installing any Autotrol brand valve. Non-silicone

grease may cause plastic components to fail

over time.

WARNING:

The inlet water must be connected

to the inlet port of the valve. When replacing non-

Autotrol valves, the inlet and outlet may be

reversed. Ensure that the plumbing is not

installed in the oppposite order. Tank media may

be pushed into the valve.

WARNING:

Filter media may need to be

properly conditioned before the filter is placed

into full operation. Consult the original equipment

manufacturer for proper procedure.

Location Selection

The following considerations must be taken into account

when selecting the location for the water conditioning

system.

• Locate the system as close to a drain as possible.

• If supplementary water treating equipment is

required, make sure that adequate additional space

is available. Locate the brine tank in an accessible

place so that salt can be easily added.

• Do not install any system with less than 10 feet

(3 m) of piping between the outlet of the conditioners

and the inlet of the water heater. Water heaters can

transfer heat down the cold water pipe into the

control valve. Hot water can severely damage the

conditioners.

A ten-foot (3-m) total pipe run (including bends, elbows,

etc.) is a reasonable distance to prevent hot water

damage. A positive way to prevent hot water from flowing

from a heat source to the conditioners is to install an

expandable accumulator tank before the hot water heater.

Always conform to local codes.

• Do not locate the unit in an area where the ambient

temperature is ever below 34

o

F (1

o

C) or over

120

o

F (49

o

C).

• Maximum allowable water temperature is

100

o

F (38

o

C).

• Do not install the unit near acid or acid fumes.

• Do not expose the unit to petroleum products.

Water Line Connection

A bypass valve system must be installed to accommodate

occasions when the water conditioning system must be

bypassed for supplying hard water or servicing. See

Figures 7 and 8.

Figure 8

Unit in Bypass

Unit in Service

B

Y

P

A

S

S

B

Y

P

A

S

S

B

Y

P

A

S

S

B

Y

P

A

S

S

Wt

Wt

Conditioning

Conditioning

System

System

Not in Bypass

In Bypass