10009459 7

Brookhaven Direct Vent Gas Fireplace

FP297A

INSTA VENT FREE

UVHB26 GAS SUPPLY

7/1/98

FP297A

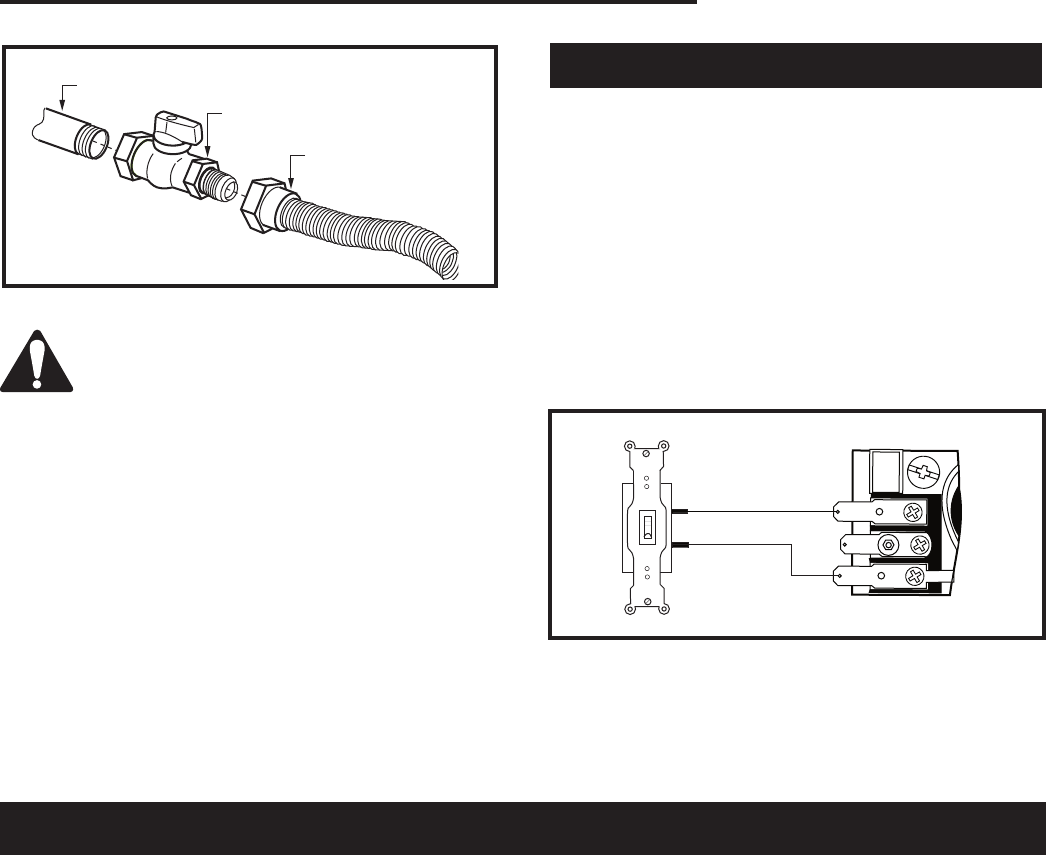

1/2” Gas Supply

1/2” NPT x 1/2” Flare Shut-

off Valve

3/8” Flex Line

(From Valve)

Fig. 5 Typical gas supply installation.

The fireplace valve must not be subjected

to any test pressures exceeding 1/2 psi.

Isolate or disconnect this or any other gas

appliance control form the gas line when

pressure testing.

The gas control is equipped with a captured screw type

pressure test point, therefore it is not necessary to pro-

vide a 1/8” test point up stream of the control.

When using copper or flex connector use only approved

fittings. Always provide a union when using black iron

pipe so the gas line can be easily disconnected for

burner or fan servicing. See gas specification for pres-

sure details and ratings.

The fireplace valve must not be subjected to any test

pressures exceeding 1/2 psi. Isolate or disconnect this

and any other gas appliance control from the gas line

when pressure testing.

Remote ON/OFF Switch

Do not wire the remote ON/OFF wall switch for this gas

appliance into a 120v power supply.

1. Thread wire through the electrical knockout located

on either side of the unit. Take care not to cut the

wire or insulation on metal edges. Ensure the wire is

secured and protected form possible damage. Run

one end of the gas control valve and the other end to

the conveniently located wall switch.

2. Attach the wire to the ON/OFF switch and install

switch into receptacle box. Attach cover plate to

switch.

3. Connect wiring to gas valve. (Fig. 6)

TPTH

TH

TP

FP1218

Remote switch

wiring

8/02

Remote ON/OFF Switch

FP1218

Fig. 6 Remote switch wiring diagram for R models.

Your fireplace is approved to be vented either through

the side wall, or vertically through the roof.

• Only CFM Corporation venting components specifi-

cally approved and labelled for this fireplace may be

used.

• If vent termination is installed in an accessible loca-

tion, Vent Termination Guard #53525 shall be in-

stalled.

• Vent terminations shall not be recessed into a wall or

siding.

• Horizontal venting which incorporates the twist lock

pipe must be installed on a level plane without an

inclining or declining slope.

• Horizontal venting which incorporates the use of flex

venting shall have an inclining slope from the unit of

1/2” (13 mm) per 12” (305 mm).

General Venting

There must not be any obstruction such as bushes,

garden sheds, fences, decks or utility buildings within

24” (610 mm) from the front of the termination hood.

Do not locate termination hood where excessive snow

or ice build up may occur. Be sure to check vent termi-

nation area after snow falls, and clear to prevent ac-

cidental blockage of venting system. When using snow

blowers, make sure snow is not directed towards vent

termination area.

Location of Vent Termination

It is imperative the vent termination be located observ-

ing the minimum clearances as shown on the next

page.

*Check with local codes or in absence of same with

CSA B149.1 Installation Codes (1991) for Canada

or follow the current National Fuel Gas Code, ANSI

Z223.1/NFPA 54 for installations in the USA.