27

Vermont Castings Intrepid Multi-Fuel

2000970

7. For doors, replace the doors and close them on

a piece of waxed paper to keep the cement from

migrating onto the stove front, or tap other parts with

the rubber mallet (or hammer/block of wood).

8. Clean excess cement from around the channel. Let

the cement that holds the new gasket dry thoroughly.

Adjust the Door if Necessary

The door latch or damper mechanism may need adjust-

ment after you have regasketed them. Initially, it may

require loosening to accommodate the new gasket; af-

ter a few weeks, it may need tightening to compensate

for compression of the new gasket. The directions for

adjusting the latch and damper are on page 26.

Permanent Gaskets

Other gaskets seal between non-moving parts, but

these are not subject to the same wear and deteriora-

tion as gaskets on moving parts. It is unlikely that you

will ever need to replace these gaskets unless the

involved parts are disassembled and then put back

together. If this is the case, the job should be done only

by a qualified service technician. The diameter of the

gasket that seals these non-moving parts is 5/16”, and

the areas sealed are the flue collar to the stove back;

and the lower fireback to the sides. Refer to Page 26 for

information on the glass panels and their gaskets.

ST559

Remove

gasket

11/30/00 djt

ST560

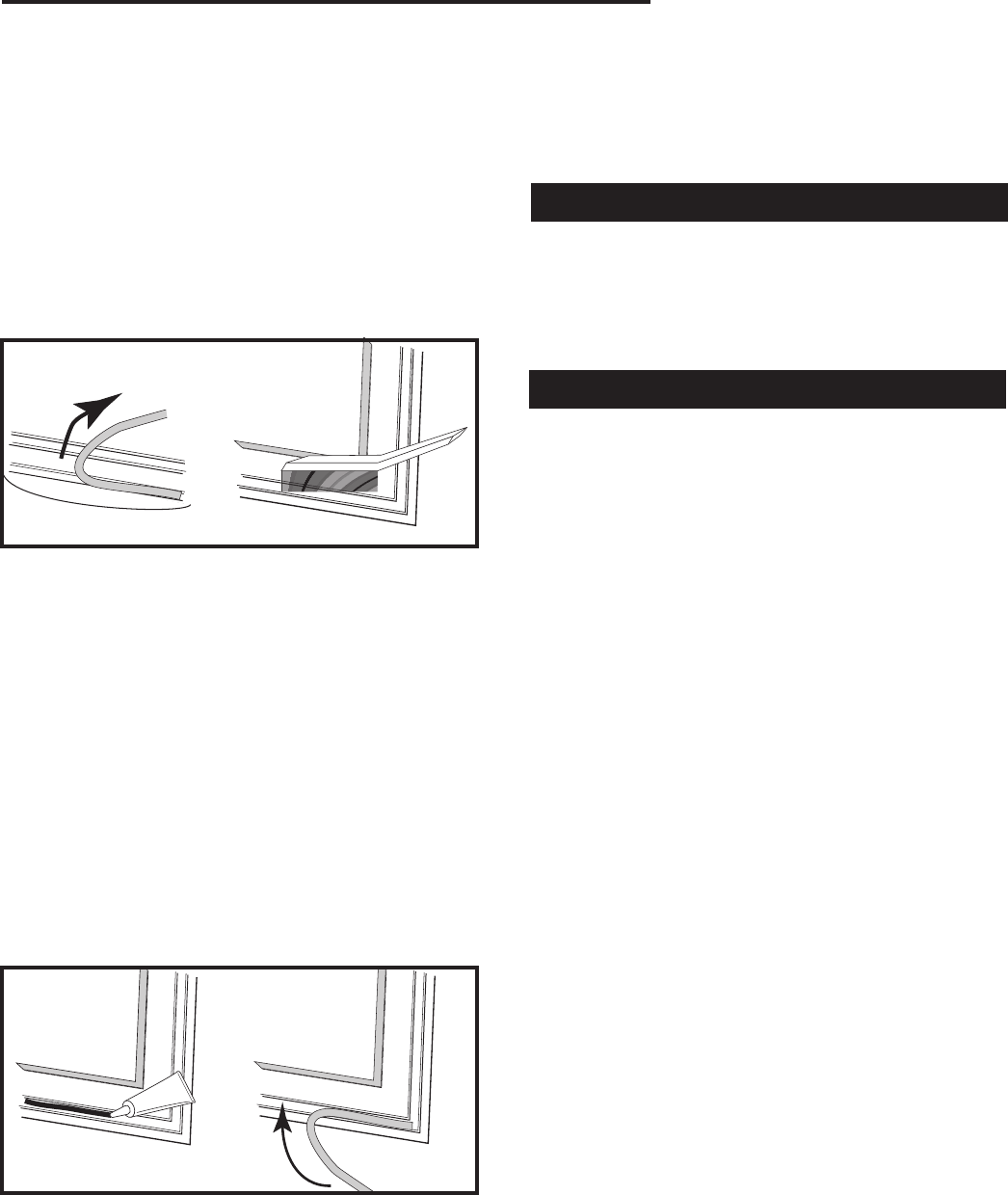

Fig. 43 Remove gasket then clean channel with wire brush.

Wait until the fire is out and the stove has cooled. Be

sure to follow the standard safety procedure for working

with dusty materials: Wear safety goggles and a dust

mask.

The procedure for replacing the gaskets is the same,

regardless of the gasket location.

1. Remove the existing gasket by grasping an end and

pulling firmly.

2. Use a wire brush or a screwdriver to clean the

channel of any remaining cement or bits of gasket.

Remove stubborn deposits of cement with a cold

chisel if necessary. (Fig. 43)

3. Determine the correct length of the appropriate-sized

gasket by laying it out in the channel. Allow an extra

1-2” (25-51 mm) and mark the spot to be cut.

4. Remove the gasket from the channel, place it on a

wood cutting surface, and cut it at the marked spot

with a utility knife. Twist the ends slightly to keep the

gasket from unraveling.

5. Lay an unbroken 1/8” (3 mm) bead of gasket cement

in the newly-cleaned channel. Starting at one end,

press the gasket into the channel. Ensure a good

joint where the gasket meets before trimming any

excess. Do not overlap the gasket ends or leave

ends with ragged edges. (Fig. 44)

6. Press the gasketed part firmly against its normal

mating surface to seat the gasket evenly in its chan-

nel.

ST559

Remove

gask

et

11/30/00 djt

Cement

Sto

ve Gasket

ST561

Fig. 44 Lay a bead of gasket cement then press new gasket

in place.