12

Vermont Castings Intrepid Multi-Fuel

2000970

ST503

Alcove side view

11/10/00 djt

Metal

Stud

Combustible

facing may

overlap metal

studs by only

1”

1” air gap top

and bottom,

on both

sides and

back wall

7/16” Durock® (or

equivalent)

Joist Shield (Sup-

plied by Chimney

Manufacturer)

ST503

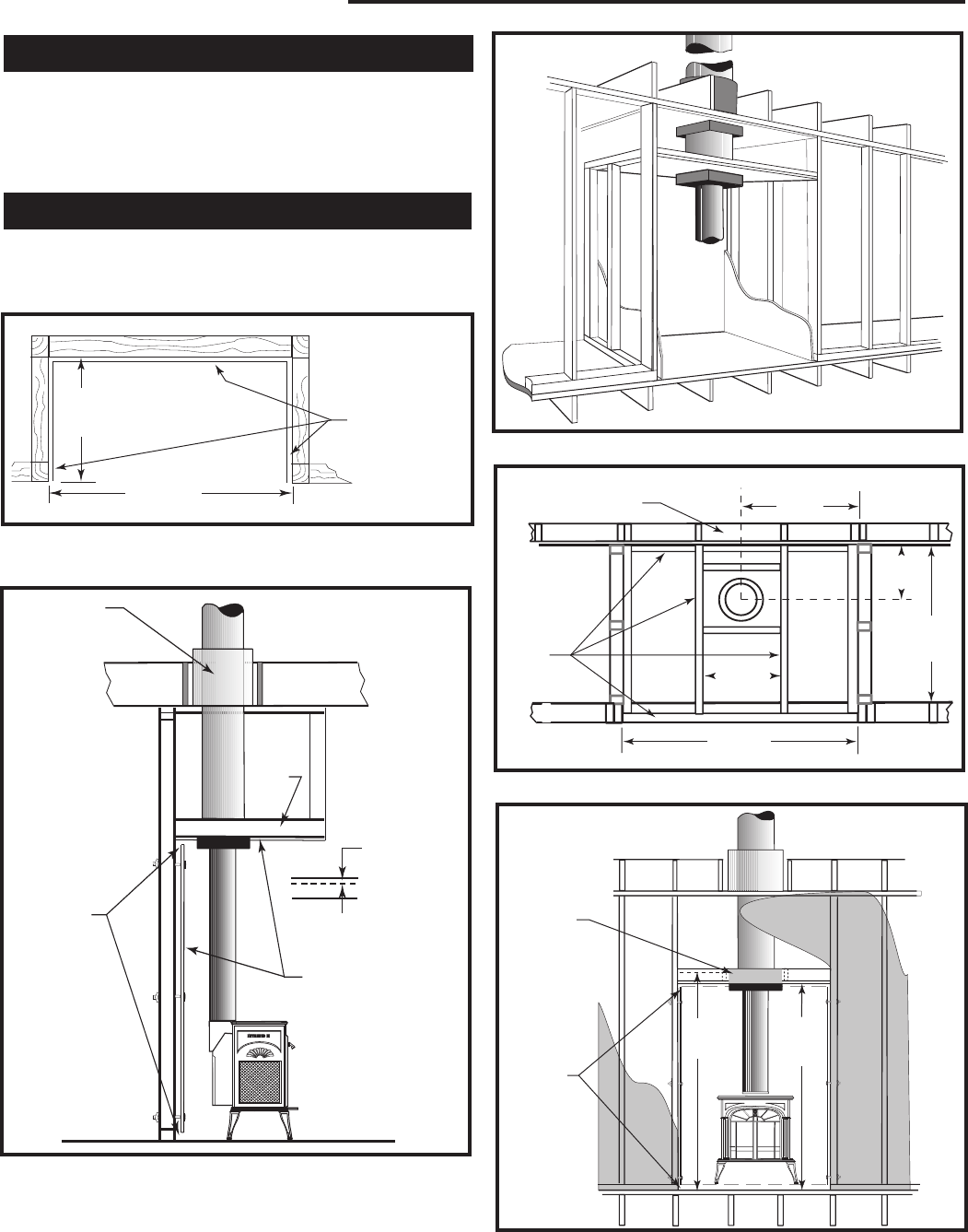

Fig. 16 Alcove side section.

Alcove Installations

Because of their restricted air flow and heat retention

characteristics, specific construction requirements and

special clearances apply to installations into alcoves.

No stove or chimney connector heat shields are used in

alcove installations.

Construction Requirements

The following illustrations show noncombustible ceiling

framing and maximum and minimum permitted dimen-

sions for alcove construction.

36"

Max.

48" Min.

ST502

Intrepid

Alcove floor plan

11/10/00 djt

Use recommended

floor protection

7/16” Durock®

(or equivalent)

spaced 1” off

wood studs on

noncombustible

spacers

ST502

Fig. 15 Alcove floor plan. Sheetrock on front face butts to Du-

rock® (or equivalent) alcove lining.

65"

62" Min.

to Alcove

Ceiling

ST506

Alco

ve front view

11/00

Ceiling sup-

port package

extends 2”

below Durock®

(or equivalent)

ceiling

1” air gap,

top, bottom,

on both

sides and

back wall

ST506

Fig. 19 Front view: 65” minimum clearance from hearth to

combustibles on front face. Combustible facing may overlap

metal studs by only 1”. It should not extend below the height of

the noncombustible ceiling.

NOTE:

From 62” to

65” must be

covered by

a noncom-

bustible

material.

St504

Alcove cutaway

11/00

ST504

Fig. 17 Cutaway perspective of alcove installation.

24"

14¹⁄₄"

48" Min.

11"

Min.

36"

Max.

ST505

Alco

ve Ceiling plan

11/00

Existing Combustible

Framing

Metal studs

support 7/16”

Durock® (or

equivalent)

ceiling

ST505

Fig. 18 Reflected ceiling plan.