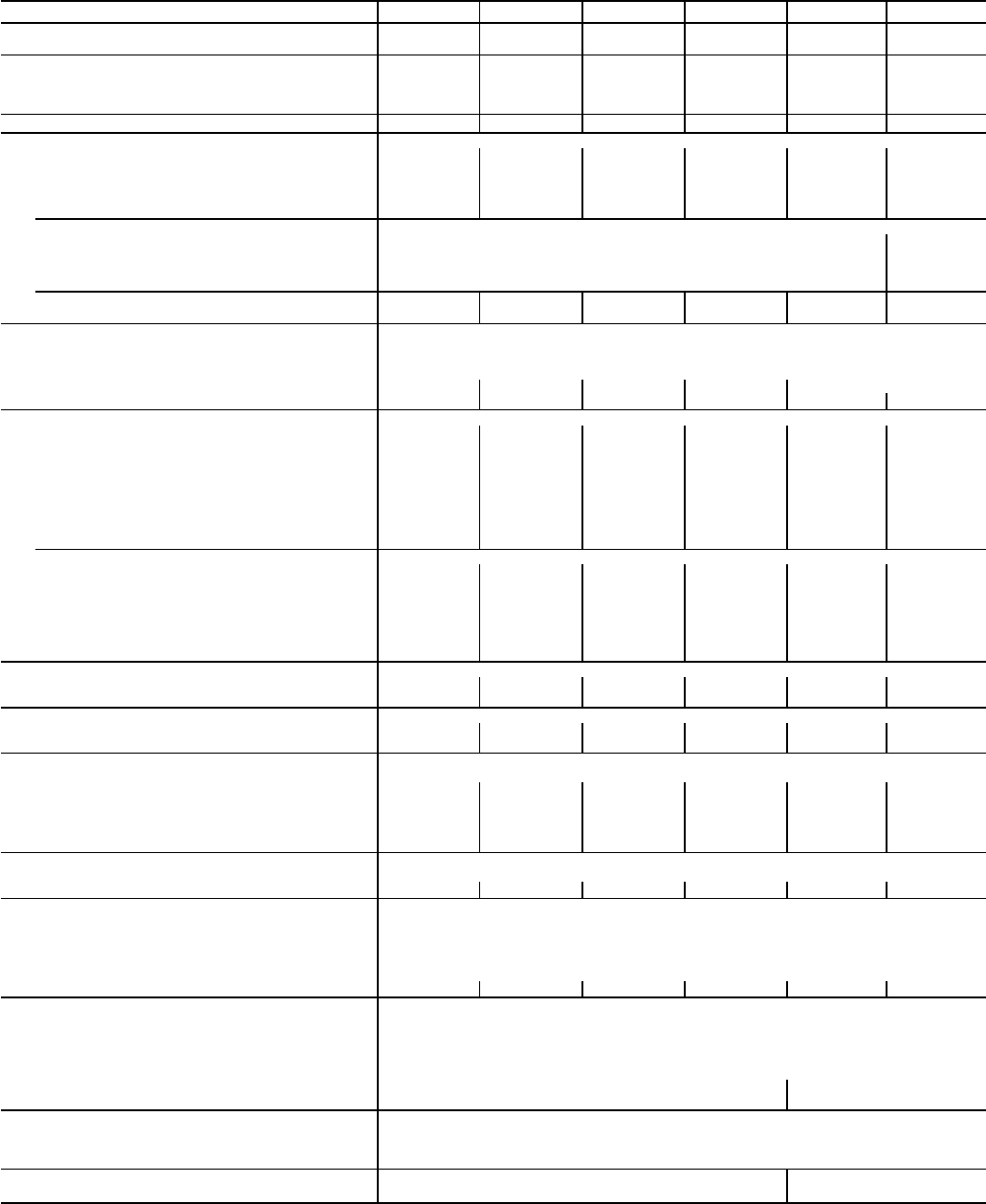

Table 1 — Physical Data

UNIT 48MA/50ME 016 024 028 030 034 040

Zone Modules (Quantity) 8 8 10 10 12 12

Nominal Cooling Capacity (tons) 15 20 25 28 30 37

OPERATING WEIGHT (lb)

Base Unit 48MA 3395 3815 4075 4080 5340 5710

Base Unit 50ME (with electric heat) 2995 3415 3675 3680 4900 5270

Roof Curb 506 506 506 506 630 630

REFRIGERANT CHARGE — R-22 (lb) 28 32 43 43 57 66.1

COMPRESSOR Reciprocating Hermetic, 1725 Rpm

No. 1 Type 06DE537 06DE824 06DE537 06DE537 06DE537 06EE250

Cylinders...Unloaders 6...2 6...2 6...2 6...2 6...2 4...1

No. 2 Type — 06DA824 06DA824 06DA537 06DA537 06EA250

Cylinders (have no unloaders) —66664

System Oil Charge (pints) 11 18 18 18 18 31

Unloader Settings (psig) Compressor No. 1 Only

Unloader No. 2

Loads 71.0 ± 1.5 —

Unloads 57.5 ± 2.5 —

Unloader No. 1

Loads 75.0 ± 1.5 75.5 ± 1.5

Unloads 62.5 ± 2.5 58.0 ± 2.5

Capacity Steps (%) 100,67,33

100,83,67

50,33,17

100,80,60

40,20

100,80,60

40,20

100,83,67

50,33,17

100,75,

50,25

CONDENSER FANS Propeller, Direct Drive

Motor Hp...Rpm...Frame (NEMA)

No. 1 1...1075...56 (Single phase)

No. 2 1...1140...56 (3 phase)

No. 3 ————1...1140...56 (3 phase)

Nominal Cfm 16,500 15,000 15,000 15,000 24,000 23,000

EVAPORATOR FANS* Centrifugal, Belt Drive

Number...Size (in.) 2...15 × 15 2...15 × 15 2...15 × 15 2...15 × 15 3...15 × 9 3...15 × 9

Cfm (Nominal) 6000 8000 10,000 10,000 12,000 12,000

Motor Hp...Rpm

Std 5...1725 7

1

⁄

2

...1725 10...1725 10...1725 15...1725 15...1725

Alt ————20...1725 20...1725

Fan Pulley

Outside Diameter (in.) 10.6 10.6 8.0 8.0 8.0 8.0

Bore (in.) 1

3

⁄

16

1

3

⁄

16

1

3

⁄

16

1

3

⁄

16

1

11

⁄

16

1

11

⁄

16

Fan Belt Number...Size

Std 1...3V630 1...3V630 2...3V560 2...3V560 2...3V630 2...3V630

Alt ————3...3V670 3...3V670

Motor Pulley Factory Installed

Outside Diameter (in.)

Std 5.3 6.0 5.0 5.0 5.0 5.0

Alt ————6.06.0

Bore (in.) 1

1

⁄

8

1

3

⁄

8

1

3

⁄

8

1

3

⁄

8

1

5

⁄

8

1

5

⁄

8

Resulting Fan Rpm

Std 880 995 1095 1095 1095 1095

Alt ————1320 1320

Shaft Center Line Distance (in.) 18 ± 2.5 18 ± 2.5 18 ± 2.5 18 ± 2.5 21 ± 2.5 21 ± 2.5

Maximum Fan Rpm 1300 1300 1300 1300 1550 1550

CONDENSER COOLING COIL Thermostatic Expansion Valve, Hot Gas Bypass

Face Area (sq ft) 6.8 6.8 6.8 6.8 10.2 10.2

Corrugated Fins/in. ...Rows 13...2 13...2 13...2 13...2 13...2 13...3

EVAPORATOR COILS (zone) Solenoid Valve and Capillary Tube for each

Number...Face Area (sq ft/ea) 8...2.12 8...2.12 10...2.12 10...2.12 12...2.01 12...2.01

Corrugated Fins/in. ...Rows 13...3 13...3 13...3 13...3 12...3 15...3

HEATING SECTION (48MA) One Heat Assembly in Each Zone Module

Rise Range 25 F to 55 F at 0.75 in. wg ESP

Input (1000 Btuh)

Total 432 432 540 540 648 648

Each Module 54 54 54 54 54 54

Bonnet Cap.† (1000 Btuh)

Total 324 324 405 405 486 486

Each Module 40.5 40.5 40.5 40.5 40.5 40.5

Burner Spud Qty...Size 2...38 2...38 2...38 2...38 2...38 2...38

OPTIONAL HEATING SECTION (50ME Electric)

Electric Heaters Nichrome, Open-Wire Resistance Element in Each Zone Module

Qty...Elements (each)** 8...2 or 3 8...2 or 3 10...2 or 3 10...2 or 3 12...2 or 3 12...2 or 3

OPTIONAL HEATING SECTION

(50ME Glycol Coil)

One Heating Coil in Each Zone Module

Maximum Allowable Inlet Temperature (F) 200

Maximum Allowable Flow, Each Coil (Gpm) 6

Solution Mixture 20% Glycol

Maximum Allowable Working Pressure (Psig) 30

Total Internal Volume (Gal) 2.61 2.61 3.15 3.15 3.76 3.76

PRESSURE SWITCHES

Low-Pressure (Psig)

Cutout 29±5

Cut-in 39±5

High-Pressure (Psig)

Cutout 400±5

Cut-in 300±5

Indoor Airflow Switch (AFS1)

Factory Setting (cfm) 6000 9000

Adjustment Range (cfm) 4000-6000 6000-9000

INDOOR AIR FILTERS

Standard Qty...Size (in.) 12...20 × 25 × 2

High Efficiency (optional)

Qty...Size (in.)

12...20 × 25 × 2 (36.5% Efficient)

OUTDOOR AIR FILTERS

Qty...Size (in.) 2...20 × 25 × 1 2...32 × 35 × 1

LEGEND

ESP — External Static Pressure

NEMA — National Electrical Manufacturers Association

*Standard unit shipped with standard motor, pulley, and belt(s); alternate unit shipped with alternate motor, pulley, and belt(s).

†The heating efficiency rating is a product thermal efficiency rating determined under continuous operating conditions independent of any installed system.

**See Field Power Supply Wiring section on page 10 and Table 4 for details.

6