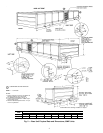

Unit has factory-installed gas shutoff valves. Install gas

shutoff valve external to unit if required by code (Fig. 8).

After piping is complete, pressurize gas line and check for

leaks with soap and water solution.

Do not use an open flame when checking for gas leaks.

Optional Glycol Connections (50ME) — Each zone

module has its own glycol heating coil and 115-v solenoid

valve. Heating coils are connected in parallel to common sup-

ply and return manifolds. Supply manifolds are equipped with

bleed cocks. Supply and return connections are shown in

Fig. 2 and 5. Unit does not have internal pressure relief for

part-load operation. Maximum allowable system working pres-

sure is 30 psig. Unit ratings are based on 20% glycol solu-

tions. Install solution supply apparatus in accordance with

application requirements, and mix glycol solution percent-

age in accordance with glycol manufacturer’s recommenda-

tions. Freeze-up protection is not factory installed.

Field Power Supply Wiring — When installed, unit

must be electrically grounded in accordance with local codes

or, in the absence of local codes, with the National Electrical

Code (NEC).

Unit has a circuit breaker for each compressor, each fan

motor, and for each 50ME electric resistance heater assem-

bly (if unit is so equipped). If required by local code, pro-

vide an additional disconnect switch in accordance with code

being followed.

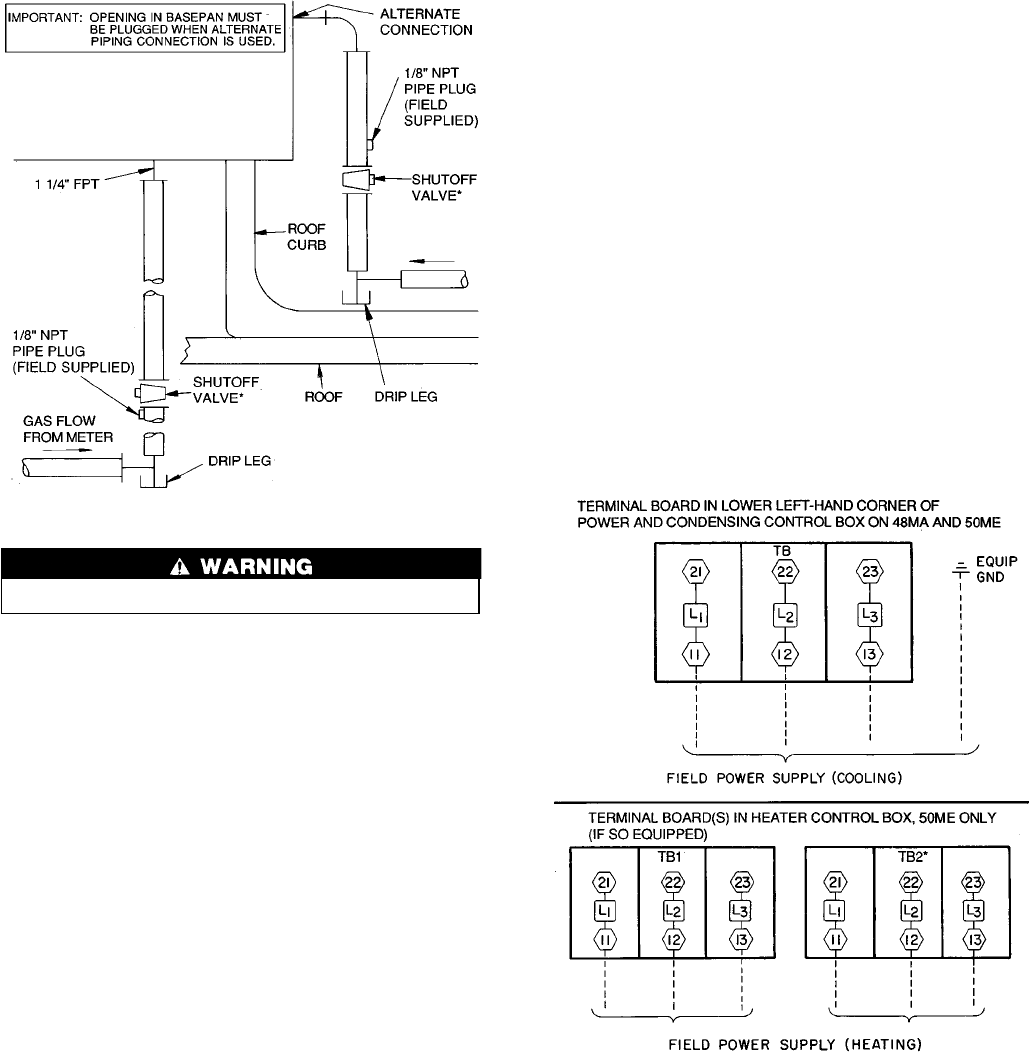

All units have a main power supply terminal board in the

power and condensing control box. The electric resistance

heater power supply terminal board(s) (if unit is so equipped)

on 50ME units is located in the heater control box at front

of unit. See Fig. 2, 5, and 9.

All terminal boards are suitable for use with copper or

aluminum wire.

Connect electrical conduit (a threaded pipe nipple) shipped

with unit to threaded fitting in roof curb and bottom of main

power and condensing section control box. Route main power

wires through conduit to terminal board in box as shown on

unit label wiring diagram and in Fig. 9.

When installing 48MA,50ME040 units with optional 20-hp

motor, the electrical conduit interconnecting the curb and con-

trol box power wire openings will not accommodate alumi-

num wire of the size that may be required. If aluminum wire

cannot be accommodated, an external transition box and short

lengths of no. 300 kcmil, 75 C copper wire from the tran-

sition box to the unit main power connection are

recommended.

Voltage to compressor terminals during compressor op-

eration must be within voltage range indicated on unit name-

plate. Phases must be balanced within 2%.

*Shutoff valve not used except where required by code.

Properly cap any gas connection not being used.

Fig. 8 — Suggested Gas Piping (48MA)

LEGEND

EQUIP — Equipment

GND — Ground

TB — Terminal Board

*208/230 v units only.

Fig. 9 — Field Power Supply Details

10