Condenser Fans

Shut off service switch to deenergize condenser-fan

motors.

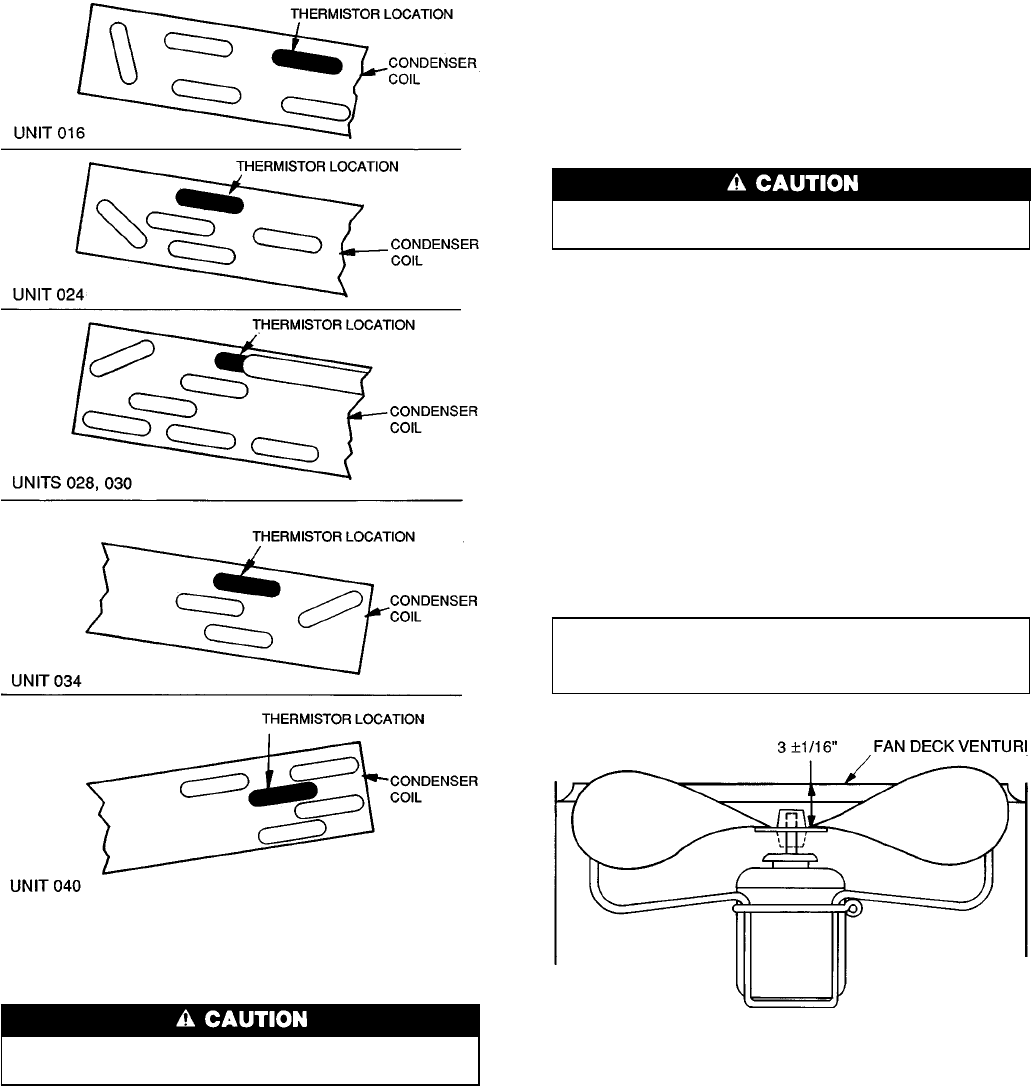

ADJUSTMENT — Remove fan guard from top of unit. Re-

move rubber hubcap from fan hub and loosen fan hub set-

screws. Adjust fan height using a straight edge laid across

fan deck venturi (Fig. 38). Tighten setscrews and replace rub-

ber hubcap to prevent hub from rusting to motor shaft. Fill

hub recess with Permagum (or similar adhesive) if rubber

hubcap is missing.

FAN MOTOR REMOVAL — Disconnect motor electrical

leads at motor control box. Loosen fan hub setscrews and

remove fan. Loosen motor mounting band and lift out

motor.

Reverse this procedure for reassembly.

LUBRICATION — Condenser-fan motors have factory-

lubricated bearings. No relubrication is necessary for the first

3 to 5 years of continuous operation except in excessively

dirty outdoor-air applications.After the first relubrication bear-

ings must be opened, cleaned, and repacked annually with

light- to medium-duty multi-purpose grease.

Evaporator Fans and Motor

Shut off service switch to deenergize evaporator-fan

motor.

MOTOR REMOVAL — Disconnect motor power wires at

conduit connection on unit junction box. Then remove mo-

tor and conduit assembly from unit.

FAN SHAFT BEARING REMOVAL

1. Remove fan motor and belts.

2. Loosen the locknut on each shaft bearing collar and re-

move the fan drive pulley.

3. Loosen the fan wheel locknuts and slide out fan shaft.

4. Remove the 2 bearings.

Reverse steps 1-4 to reassemble.

FAN SPEED ADJUSTMENT — Pulley listed in Table 1 is

factory installed in the unit.

If the factory-supplied pulley is not suitable, provide a field-

supplied pulley of the correct size as required. Refer to

Table 1 for additional fan data.

IMPORTANT: Increasing fan speed increases load on

motor. Do not exceed maximum fan motor full load

amperage (Tables 2 and 3).

Fig. 37 — Motormasterா Thermistor

Locations on Condenser Coil

Fig. 38 — Condenser-Fan Adjustment

41