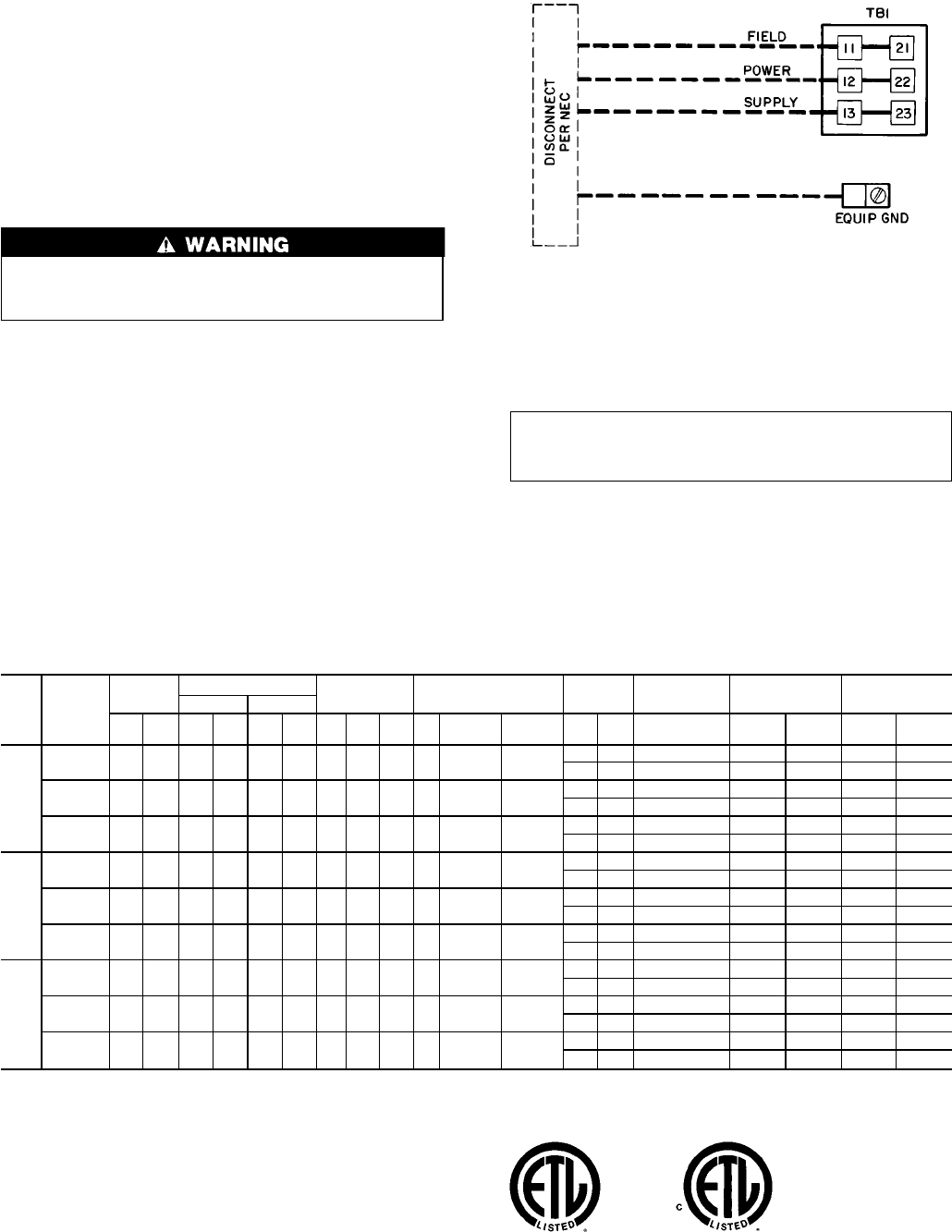

Step 8 — Make Electrical Connections

FIELD POWER SUPPLY — Unit is factory wired for volt-

age shown on unit nameplate.

When installing units, provide a disconnect per NEC

(National Electrical Code) of adequate size (Table 2).

All field wiring must comply with NEC and local

requirements.

Route power and ground lines through control box end

panel or unit basepan (see Fig. 4 and 5) to connections as

shown on unit wiring diagram and Fig. 14.

The unit must be electrically grounded in accordance

with local codes and NEC ANSI/NFPA 70 (National Fire

Protection Association).

Field wiring must conform to temperature limitations for

type ‘‘T’’ wire. All field wiring must comply with NEC and

local requirements.

Transformer no. 1 is wired for 230-v unit. If 208/230-v

unit is to be run with 208-v power supply, the transformer

must be rewired as follows:

1. Remove cap from red (208 v) wire.

2. Remove cap from orange (230 v) spliced wire.

3. Replace orange wire with red wire.

4. Recap both wires.

IMPORTANT: BE CERTAIN UNUSED WIRES

ARE CAPPED. Failure to do so may damage the

transformers.

Operating voltage to compressor must be within voltage

range indicated on unit nameplate. On 3-phase units, volt-

ages between phases must be balanced within 2%.

Table 2 — Electrical Data

UNIT

48HJ

NOMINAL

VOLTAGE

(3 Ph,

60 Hz)

VOLTAGE

RANGE

COMPRESSOR

OFM IFM

POWER

EXHAUST

COMBUSTION

FAN MOTOR

POWER SUPPLY

DISCONNECT

SIZE

No. 1 No. 2

Min Max RLA LRA RLA LRA Qty

FLA

(ea)

LRA

(ea)

Hp FLA LRA FLA LRA FLA MCA MOCP* FLA LRA

015

208/230 187 254 39.7 228 — — 3 1.7 3.8 3.7 10.5/10.5 84.5/84.5

— — 0.57 65/65 100/100 64/64 324/324

4.6 18.8 0.57 70/70 100/100 70/70 343/343

460 414 508 19.9 114 — — 3 0.8 1.9 3.7 4.8 42.3

— — 0.30 32 50 32 162

2.3 6.0 0.30 34 50 34 168

575 518 632 16.0 91 — — 3 0.75 1.5 3 3.9 23.4

— — 0.57 26 40 26 119

2.1 4.8 0.57 28 40 29 124

017

208/230 187 254 28.2 160 28.2 160 3 1.7 24.8 5 15.8/15.8 105/91

— — 0.57 84/84 110/100 90/90 499/485

4.6 18.8 0.57 89/89 110/110 95/95 518/504

460 414 508 14.1 80 14.1 80 3 0.8 10.8 5 7.9 46

— — 0.30 42 50 45 238

2.3 6.0 0.30 44 50 47 244

575 518 632 11.3 64 11.3 64 3 0.75 8.4 5 6.0 37

— — 0.57 34 40 36 190

2.1 4.8 0.57 36 45 39 195

025

208/230 187 254 35.6 198 35.6 198 2 5.5 24.8 10 28.0/28.0 193/168

— — 0.57 119/119 150/150 127/127 639/614

4.6 18.8 0.57 124/124 150/150 133/133 657/632

460 414 508 17.8 99 17.8 99 2 2.8 10.8 10 14.6 84

— — 0.30 60 70 65 304

2.3 6.0 0.30 63 80 67 310

575 518 632 14.3 79 14.3 79 2 3.4 8.4 10 13.0 66

— — 0.57 52 60 56 241

2.1 4.8 0.57 54 60 59 246

LEGEND

FLA — Full Load Amps

HACR — Heating,Air Conditioning and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*This is the maximum size permissible; smaller fuse size may be used where

conditions permit.

NOTES: In compliance with NEC requirements for multimotor and combina-

tion load equipment (refer to NEC Articles 430 and 440), the overcurrent pro-

tective device for the unit shall be fuse or HACR breaker. TheCanadian units

may be fuse or circuit breaker.

LEGEND

EQUIP — Equipment

GND — Ground

NEC — National Electrical Code

TB — Terminal Board

NOTE: Maximum wire size for TB1 is 2/0.

Fig. 14 — Field Power Wiring Connections

9