SERVICE

Before performing service or maintenance operations on

unit, turn off main power switch to unit. Electrical shock

could cause personal injury.

Cleaning — Inspect unit interior at beginning of eachheat-

ing and cooling season and as operating conditions require.

Remove unit top panel and/or side panels for access to unit

interior.

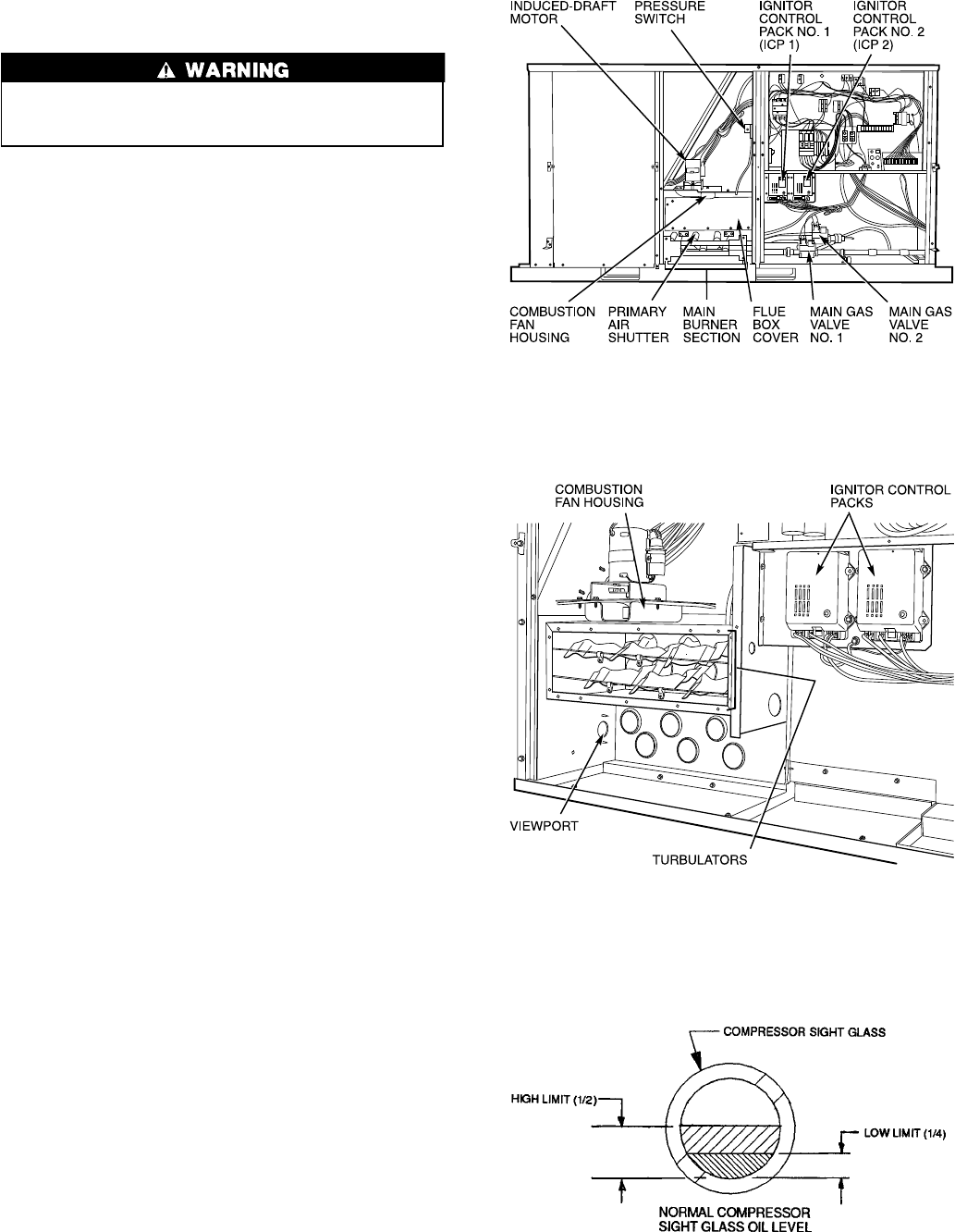

MAIN AND PILOT BURNERS —At the beginning of each

heating season, inspect for deterioration or blockage due to

corrosion or other causes. Observe the pilot and main burner

flames through view port (in condenser section), and adjust

if necessary. Refer to PilotAdjustment or Main Burners sec-

tions on pages 22 and 23.

FLUE GAS PASSAGEWAYS — The flue collector box and

heat exchanger cells may be inspected by removing heat ex-

changer access panel (Fig. 4 and 5), flue box cover, and main

burner assembly (Fig. 25). Refer to Main Burners section on

page 23 for burner removal sequence. If cleaning is re-

quired, remove heat exchanger turbulators (Fig. 26) and clean

all parts with a wire brush.

COMBUSTION-AIR BLOWER — Clean periodically to as-

sure proper airflow and heating efficiency. Inspect blower

wheel every fall and periodically during heating season. For

the first heating season, inspect blower wheel bi-monthly to

determine proper cleaning frequency.

To inspect blower wheel, remove heat exchanger access

panel. Shine a flashlight into opening to inspect wheel. If

cleaning is required, remove motor and wheel assembly by

removing screws holdingmotor mounting plate to top of com-

bustion fan housing (Fig. 25 and 26). The motor and wheel

assembly will slide up and out of the fan housing. Remove

the blower wheel from the motor shaft and clean with a de-

tergent or solvent. Replace motor and wheel assembly.

EVAPORATOR COIL — Clean as required with commer-

cial coil cleaner.

CONDENSER COIL — Clean condenser coil annually and

as required by location and outdoor-air conditions. Inspect

coil monthly; clean as required.

CONDENSATE DRAIN — Check and clean each year at

start of cooling season. In winter, keep drains and traps dry.

FILTERS — Clean or replace at start of each heating and

cooling season, or more often if operating conditions re-

quire. Refer to Table 1 for type and size.

OUTDOOR-AIR INLET SCREENS — Clean screens with

steam or hot water and a mild detergent. Do not use dis-

posable filters in place of screens.

Lubrication

COMPRESSORS — Each compressor is charged with the

correct amount of oil at the factory. Observe the level in the

sight glass immediately after shutdown while the oil is still

warm. If the oil level is observed when the oil is cold, the

level observed may be a mixture of oil and refrigerant which

is not a true indication of the oil level. If oil level observed

is not between the low limit and high limit levels as indi-

cated in Fig. 27, add oil until it is in the correct range.

Fig. 25 — Typical Gas Heating Section

(48HJE015, 48HJE017, and 48HJD025 Shown)

Fig. 26 — Typical Heating Section With

Main Burners Removed

(48HJE015, 48HJE017, and 48HJD025 Shown)

Fig. 27 — Compressor Sight Glass Oil Level

18