41

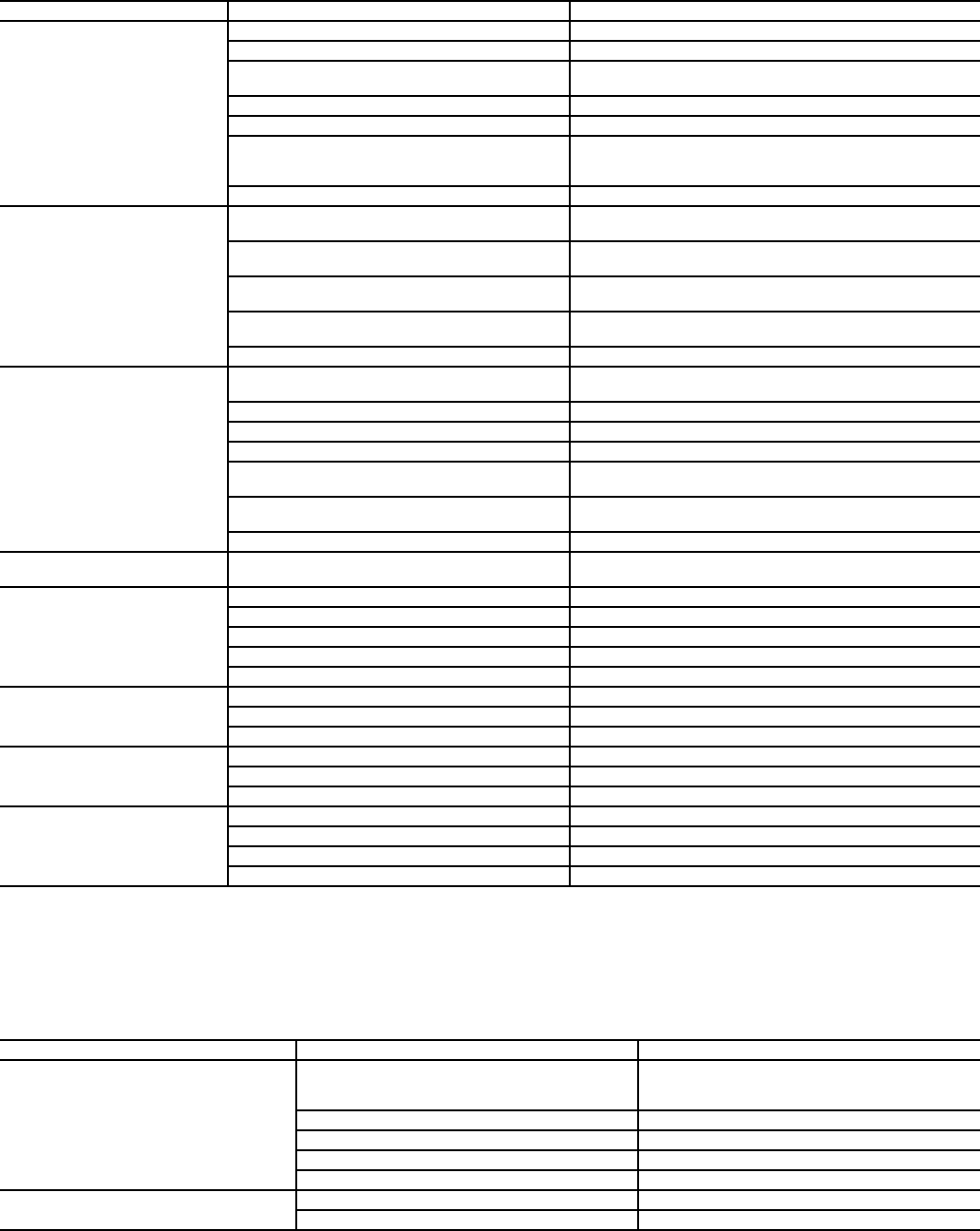

Table 3 — Heating and Cooling Troubleshooting

LEGEND

*Energy recovery section uses TXVs with a 100 psig maximum operating pressure (MOP) feature to limit suction pressure

in Cooling mode at high temperatures. Always consult charging chart for correct operating pressures.

Table 4 — Supply-Air Damper Troubleshooting

LEGEND

OCR —

Occupied Relay

PROBLEM CAUSE REMEDY

Compressor and outdoor fan

will not start.

Power failure. Call power company.

Fuse blown or circuit breaker tripped. Replace fuse or reset circuit breaker.

Defective thermostat, contactor, transformer, con-

trol relay, or capacitor.

Replace component.

Insufficient line voltage. Determine cause and correct.

Incorrect or faulty wiring. Check wiring diagram and rewire correctly.

Light Commercial Thermidistat program in UC1

or UC2 mode.

Check Light Commercial Thermidistat program. See Step 5

— Conduct Light Commercial Thermidistat Start-Up and

Checkout on page 33.

Defective fan motor. Replace fan motor.

Compressor will not start but

outdoor fan runs.

Faulty wiring or loose connection in compressor

circuit.

Check wiring and repair or replace.

Compressor motor burned out, seized, or internal

overload open.

Determine cause. Replace compressor.

Defective run/start capacitor, overload, start relay,

Time Guard® device.

Determine cause and replace.

No DEHUM signal from Light Commercial

Thermidistat.

Check for DEHUM signal on Light Commercial Thermidistat

LCD display.

Time Guard device not timed out. Allow time for Time Guard device to recycle unit.

Compressor cycles (other

than normally satisfying

thermostat).

Refrigerant overcharge or undercharge. Recover refrigerant, evacuate system, and recharge to

nameplate.

Defective compressor. Replace and determine cause.

Insufficient line voltage. Determine cause and correct.

Blocked outdoor coil or dirty air filter. Determine cause and correct.

Defective run/start capacitor, overload, or start

relay.

Determine cause and replace.

Faulty outdoor-fan (cooling) or indoor-fan (heat-

ing) motor or capacitor.

Replace.

Restriction in refrigerant system. Locate restriction and remove.

Suction pressure greater than

100 psig in Cooling mode.

Defective TXV. Replace TXV.

Excessive head pressure.*

Dirty air filters. Replace filters.

Dirty coils. Clean coils.

Refrigerant overcharged. Recover excess refrigerant.

Air in system. Recover refrigerant, evacuate system, and recharge.

Condensing air restricted or air short-cycling. Determine cause and correct.

Head pressure too low.*

Low refrigerant charge. Check for leaks; repair and recharge.

Compressor valves leaking. Replace compressor.

Restriction in liquid tube. Remove restriction.

Excessive suction pressure.*

High heat load. Check for source and eliminate.

Compressor valves leaking. Replace compressor.

Refrigerant overcharged. Recover excess refrigerant.

Suction pressure too low.*

Dirty air filters or coils. Replace filter, clean coils.

Low refrigerant charge. Check for leaks; repair and recharge.

Metering device or low side restricted. Remove source of restriction.

Insufficient indoor airflow. Increase air quantity. Check filter and replace if necessary.

TXV —

Thermostatic Expansion Valve

PROBLEM CAUSE REMEDY

Damper does not open; fan(s) off.

OCR not energized (thermostat in Unoccupied

mode).

Check Light Commercial Thermidistat program

settings (see Step 5 — Light Commercial Thermi-

distat Start-Up and Checkout section, page 33).

OCR defective. Replace OCR.

Damper jammed. Free damper.

Damper motor defective. Replace damper motor.

Loose wiring. Check wiring and correct.

Damper will not close.

Damper jammed. Free damper.

Motor return spring broken. Replace motor.