38

TROUBLESHOOTING

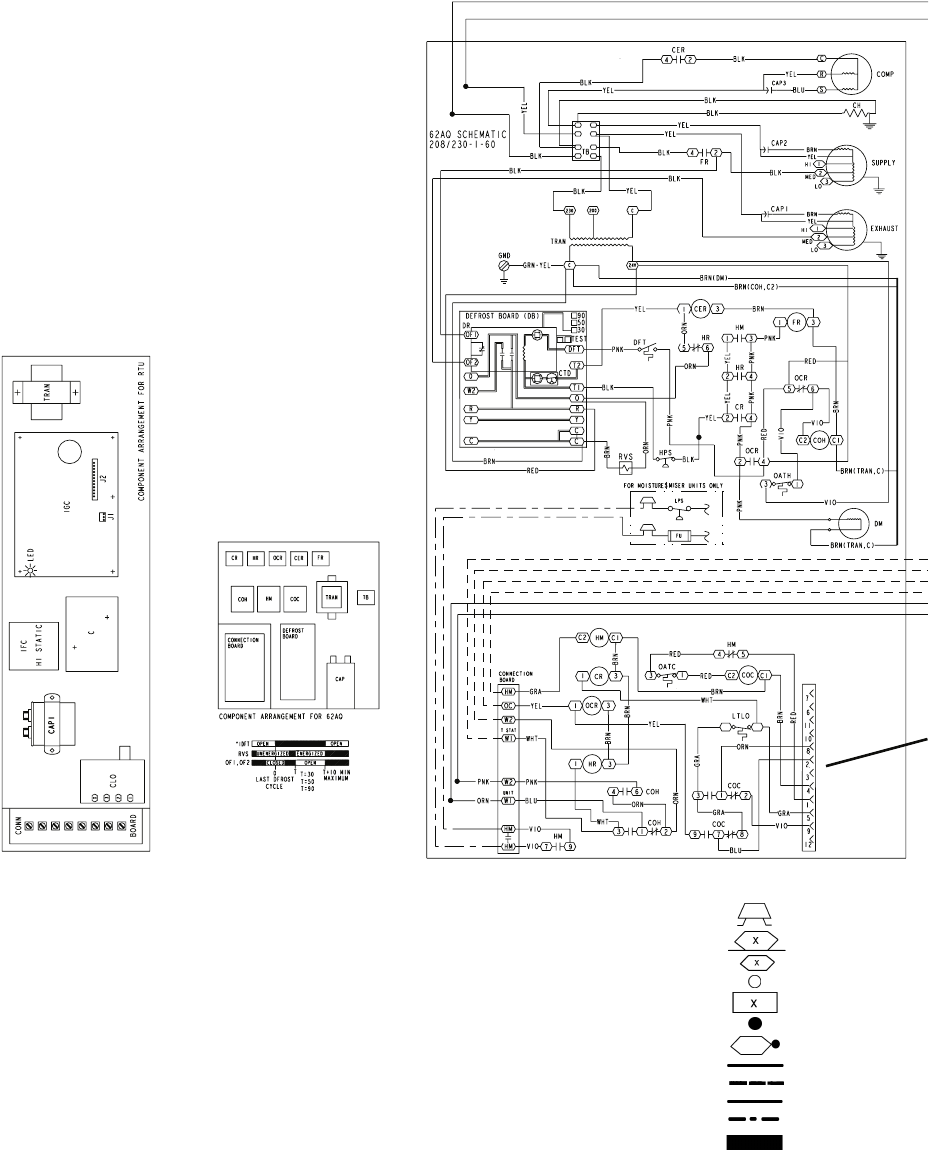

Use Tables 3 and 4, and Fig. 19 and 20 when troubleshooting this unit.

C — Contactor

CAP — Capacitor

CER — Compressor Energy Recovery section

CH — Crankcase Heater

CLO — Compressor Lockout

COC — Cool Changeover Relay

COH — Heat Changeover Relay

COMP — Compressor Motor

CR — Cooling Relay

CTD — Compressor Time Delay

DB — Defrost Board

DFT — Defrost Thermostat

DM — Damper Motor

DR — Defrost Relay

EQUIP — Equipment

FPT — Freeze-Up Protection Thermostat

FR — Fan Relay

FU — Fuse

GND — Ground

HM — Humidity Relay

HPS — High-Pressure Switch

HR — Heating Relay

HS — Hall Effect Sensor

I — Ignitor

IDM — Induced Draft Motor

IFC — Indoor Fan Contactor

IFM — Indoor Fan Motor

IGC — Integrated Gas Unit Control (48HJ only)

LTL O — Low Temp Cooling Lockout

LPS — Low-Pressure Switch

LS — Limit Switch

MGV — Main Gas Valve

OATC — Outdoor-Air Thermostat (Cool)

OATH — Outdoor-Air Thermostat (Heat)

OCR — Occupied Relay

OF — Outdoor Fan

OFM — Outdoor Fan Motor

OLR — Overload Relay

PL — Plug Assembly

QT — Quadruple Terminal

RS — Rollout Switch

RVS — Reversing Valve Solenoid

SEN — Sensor

TB — Terminal Block

TRAN — Transformer

Field Splice

Marked Wire

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Splice

Splice (Marked)

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory or Optional Wiring

To indicate common potential

only. Not to represent wiring.

NOTES:

1. If any of the original wire furnished must be replaced, it must be

replaced with Type 90° C wire or its equivalent.

2. Three phase motors are protected under primary single phasing

conditions.

3. Thermostat: HH07AT170, 172.

Subbase: HH93AZ176, 177, 178, and 179.

4. Set heat anticipator at .14 amp for 1st stage and .14 amp for 2nd

stage.

5. Use copper conductors only.

6. TRAN is wired for 230-v unit. If unit is to be run with 208-v power

supply, disconnect BLK wire from 230-v tap (ORN) and connect

to 208-v tap (RED). Insulate end of 230-v tap.

LEGEND

Fig. 19 — Typical Wiring Schematic (Standard Controls)