12

If the 208/230-v unit is to be connected to a 208-v power sup-

ply, the transformer must be rewired by moving the black wire

with the

1

/

4

-in. female space connector from the 230-volt con-

nection and moving to the 200-volt

1

/

4

-in. male terminal on the

primary side of the transformer.

Refer to unit label diagram for additional information. Pig-

tails are provided for field wire connections. Use factory-

supplied splices or UL (Underwriters’ Laboratories) approved

copper/aluminum connector.

When installing units, provide a disconnect per the NEC.

All field wiring must comply with NEC and local

requirements.

Install field wiring as follows:

1. Install conduit through side panel openings. Install con-

duit between disconnect and control box.

2. Install power lines to terminal connections as shown in

Fig. 7.

Voltage to compressor terminals during operation must be

within voltage range indicated on unit nameplate (see

Tables 1A-1H). On 3-phase units, voltages between phases must

be balanced within 2% and the current within 10%. Use the for-

mula shown in the legend for Tables 1A-1H, Note 2 to deter-

mine the percent of voltage imbalance. Operation on improper

line voltage or excessive phase imbalance constitutes abuse and

may cause damage to electrical components. Such operation

would invalidate any applicable Carrier warranty.

FACTORY-SUPPLIED NON-FUSED DISCONNECT — The

factory-supplied disconnect is capable of handling disconnect

amps up to 80 A for a COBRA Energy Recovery unit. For dis-

connect amps greater than 80 A, a field-supplied disconnect is

required.

FIELD CONTROL WIRING — Install a Carrier-approved

accessory thermidistat assembly according to installation

instructions included with the accessory. Locate thermidistat as-

sembly on a solid wall in the conditioned space to sense average

temperature in accordance with thermidistat installation instruc-

tions on page 30. Connect thermidistat wires to terminal board.

Route thermidistat cable or equivalent single leads of col-

ored wire from subbase terminals through connector on unit to

low-voltage connections (shown in Fig. 8). Thermidistat con-

trol wiring is routed to both the rooftop unit control box and the

energy recovery section control box.

If a PremierLink™ control is used, a thermidistat does not

need to be used. A humidistat and a separate room air sensor

are used. Two extra terminal blocks (TB2 and TB3) are provid-

ed in the control box for all units with PremierLink controls.

No wiring should be directly connected to the PremierLink

control. Wire sensors to TB2 or TB3. Humidistat is wired to

TB1 and energy recovery section control box.

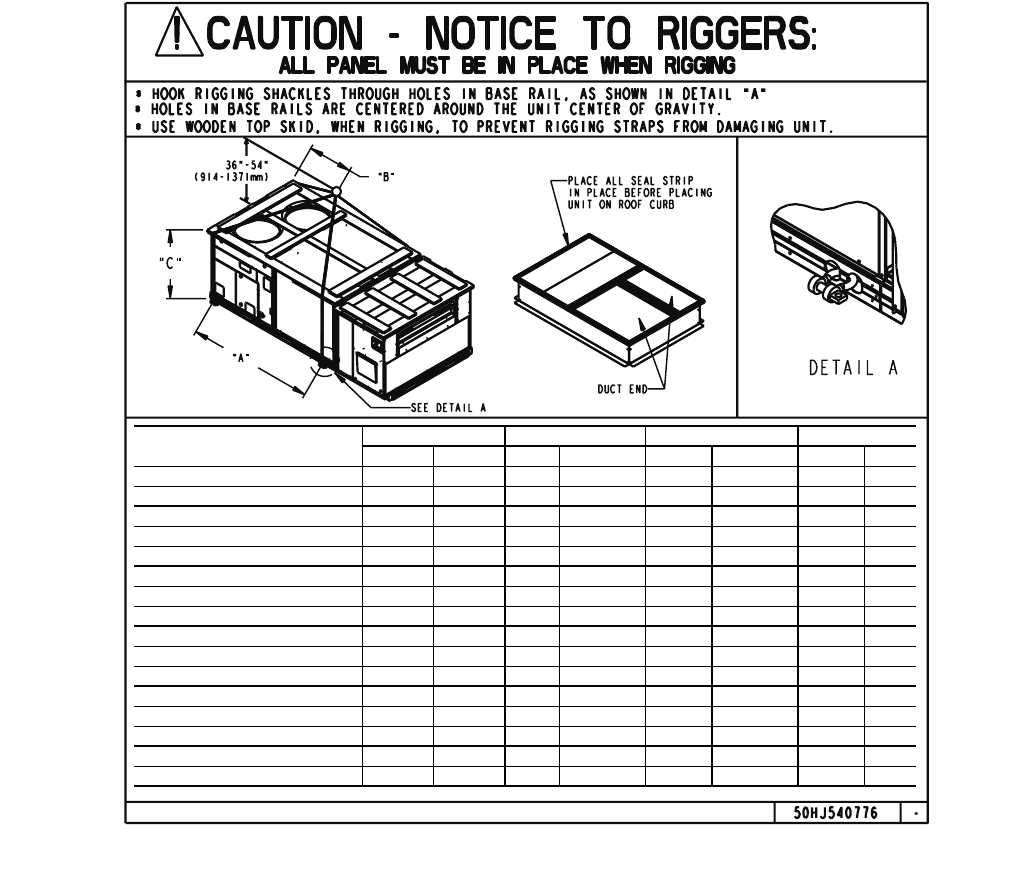

Fig. 6B — Rigging Label — COBRA™ Energy Recovery Unit — Sizes 48/50HJ008-014

MAX WEIGHT A B C

lb kg in. mm in. mm in. mm

48HJ008 w/62AQ200 1310 595 77.42 1966.5 66.50 1689.10 42.12 1070

48HJ008 w/62AQ300 1355 616 77.42 1966.5 66.50 1689.10 42.12 1070

48HJ009 w/62AQ200 1315 597 77.42 1966.5 66.50 1689.10 42.12 1070

48HJ009 w/62AQ300 1360 618 77.42 1966.5 66.50 1689.10 42.12 1070

48HJ012 w/62AQ200 1400 636 77.42 1966.5 66.50 1689.10 50.12 1273

48HJ012 w/62AQ300 1445 657 77.42 1966.5 66.50 1689.10 50.12 1273

48HJ014 w/62AQ200 1440 655 77.42 1966.5 66.50 1689.10 50.12 1273

48HJ014 w/62AQ300 1485 675 77.42 1966.5 66.50 1689.10 50.12 1273

50HJ008 w/62AQ200 1240 564 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ008 w/62AQ300 1285 584 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ009 w/62AQ200 1245 566 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ009 w/62AQ300 1290 586 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ012 w/62AQ200 1325 602 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ012 w/62AQ300 1370 623 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ014 w/62AQ200 1345 620 77.42 1966.5 66.50 1689.10 42.12 1070

50HJ014 w/62AQ300 1410 641 77.42 1966.5 66.50 1689.10 42.12 1070