28

Step 9 — Assemble and Mount Supply-Air

Hood —

The hood kit supplied with the energy recovery

section is needed to complete this installation. See Fig. 11. The

energy recovery section supply air hood installs around its

motorized damper inlet.

1. Assemble and mount supply air hood as shown in Fig. 11.

2. Discard the tape that holds the thermostats behind the

damper plates. Mount thermostats to the hood sides of the

energy recovery section unit into the holes provided, with

thermostat terminals facing up. See Fig. 11. Mount out-

side cooling set point thermostat part number

HH22HA060 (white label) on the left side of the hood.

See Fig. 11.

3. Mount the outside heating thermostat part number

HH22HA065 (red label) on the right side of the hood. See

Fig. 11.

4. From the outside of the unit’s side panels fasten the

thermostat(s) with two mounting screws, with the quick

connect terminals face up. See Fig. 11.

5. Install thermostat knobs (provided in kit). See Fig. 11.

6. Set supply air quantity

(on units with optional factory-

installed supply air fan [GA] or field-installed accessory

supply air fan kit [CRFANKIT001-006A00]). Select the

fan speed and damper position to obtain desired cfm.

Relocate damper stops to the desired position on the

damper support rail and adjust the fan speed by relocating

the wire on the supply fan motor terminal block. Factory

set position is 45 degrees for the damper position, and

medium speed for the motor. Relocate stops to top hole

for 30 degrees, bottom hole for 60 degrees, and remove

stops for 90 degrees (see Fig. 11).

7. Install the aluminum filter screen and end cap with

screws along the top, as shown in Fig. 11.

Step 10 — Mount the Barometric Relief

Damper —

The hood kit supplied with the energy recovery

section is needed to complete this installation. The exhaust air

hood (that includes the barometric relief damper) must be

assembled and installed on the energy recovery section per the

instructions below. See Fig. 12.

1. Install the barometric relief damper onto the

energy recovery section by mounting the hinge with

2 screws then sliding in the hinge pin. See Fig. 12.

2. Install damper limiter for 30, 45, or 60 degree angles.

Limiter pin not required for 90-degree setting (set to the

desired position based on CFM requirements and fan

speed). See Fig. 12. Fan speed is adjusted by relocating

wires on fan terminal blocks.

3. Loosen compressor bolts and remove shipping blocks

from under compressor on the 62AQ060 and 62AQ100

sizes only.

4. Install exhaust hood.

5. Install wire guard as shown in Fig. 12.

NOTE: Mount the hood sides to the energy recovery section

first, and then the hood top for easier installation. The ther-

mostats are shipped factory-wired and taped behind the

damper blade of the energy recovery section. Knobs and

screws are in hood package.

Never operate the unit without the wire guard in place.

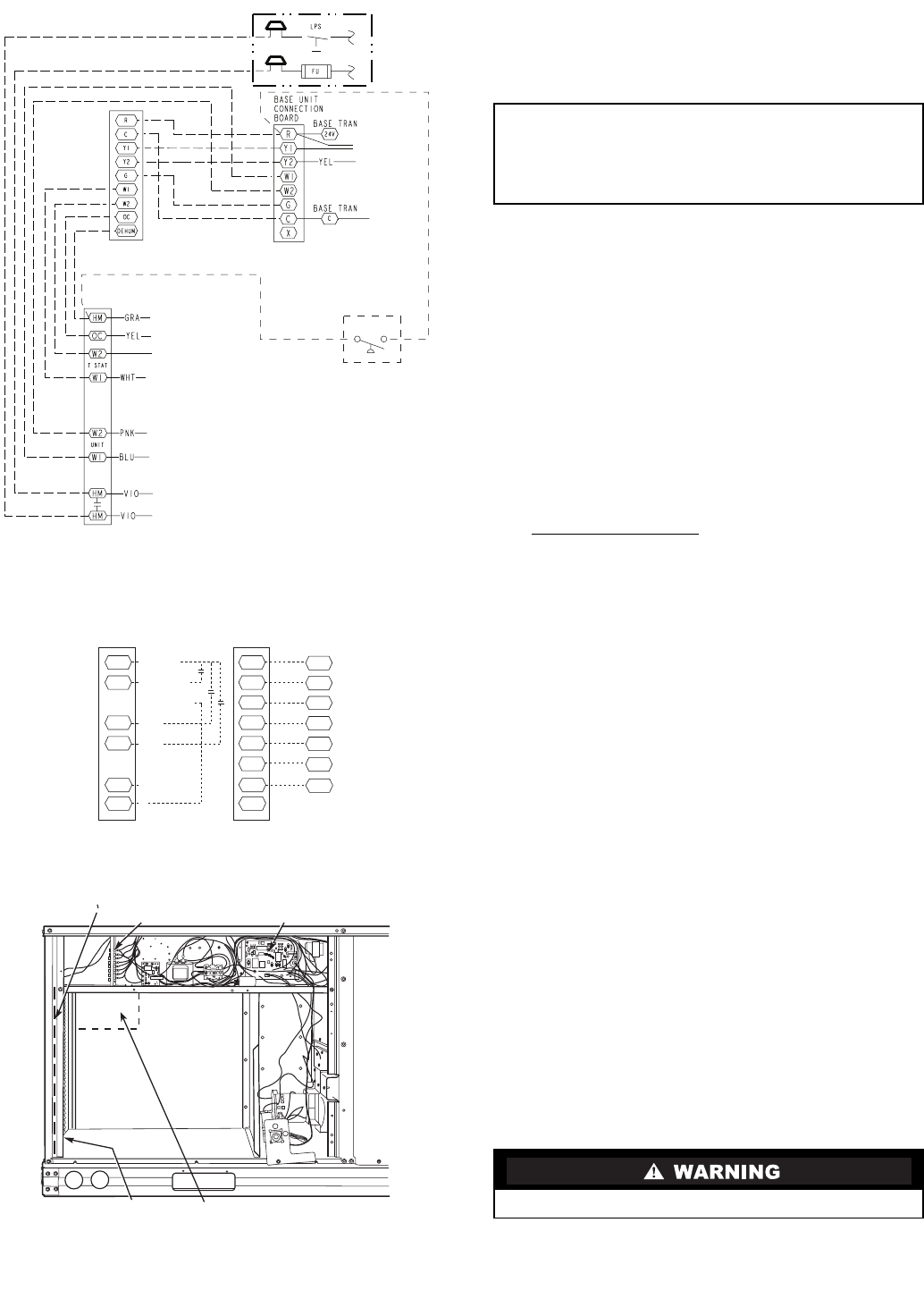

RACEWAY LOW VOLTAGE

CONNECTIONS

INTEGRATED GAS UNIT

CONTROLLER (IGC)

HOLE IN END

PANEL (HIDDEN)

PREMERLINK LOCATION

(OPTIONAL)

W2

C

Y1

G

R

Y2

W1

C

G

R

Y2

W1

X

W2

C

Y1

G

R

Y2

W1

X

24 VAC

RMTOCC

CMPSAFE

FSD

NOT USED

C

X

SFS

TB3 TB1

DDC CONTROL

CONNECTION

BOARD

FOR MOISTUREMI$ER UNITS ONLY

LIGHT

COMMERCIAL

THERMIDISTAT

ACCESSORY

OPTIONAL

HUMIDISTAT

(HL38MG029)

62AQ

CONNECTION

BOARD

Fig. 8 — Light Commercial Thermidistat

Accessory Low-Voltage Connections

Fig. 9 — Low Voltage Connections

(Units with PremierLink™ Controls)

Fig. 10 — Field Control Wiring Raceway

(48HJ Shown)