7

HEATER LOW

VOLTAGE PLUG

A05388

Fig. 8 -- Control Box Wiring

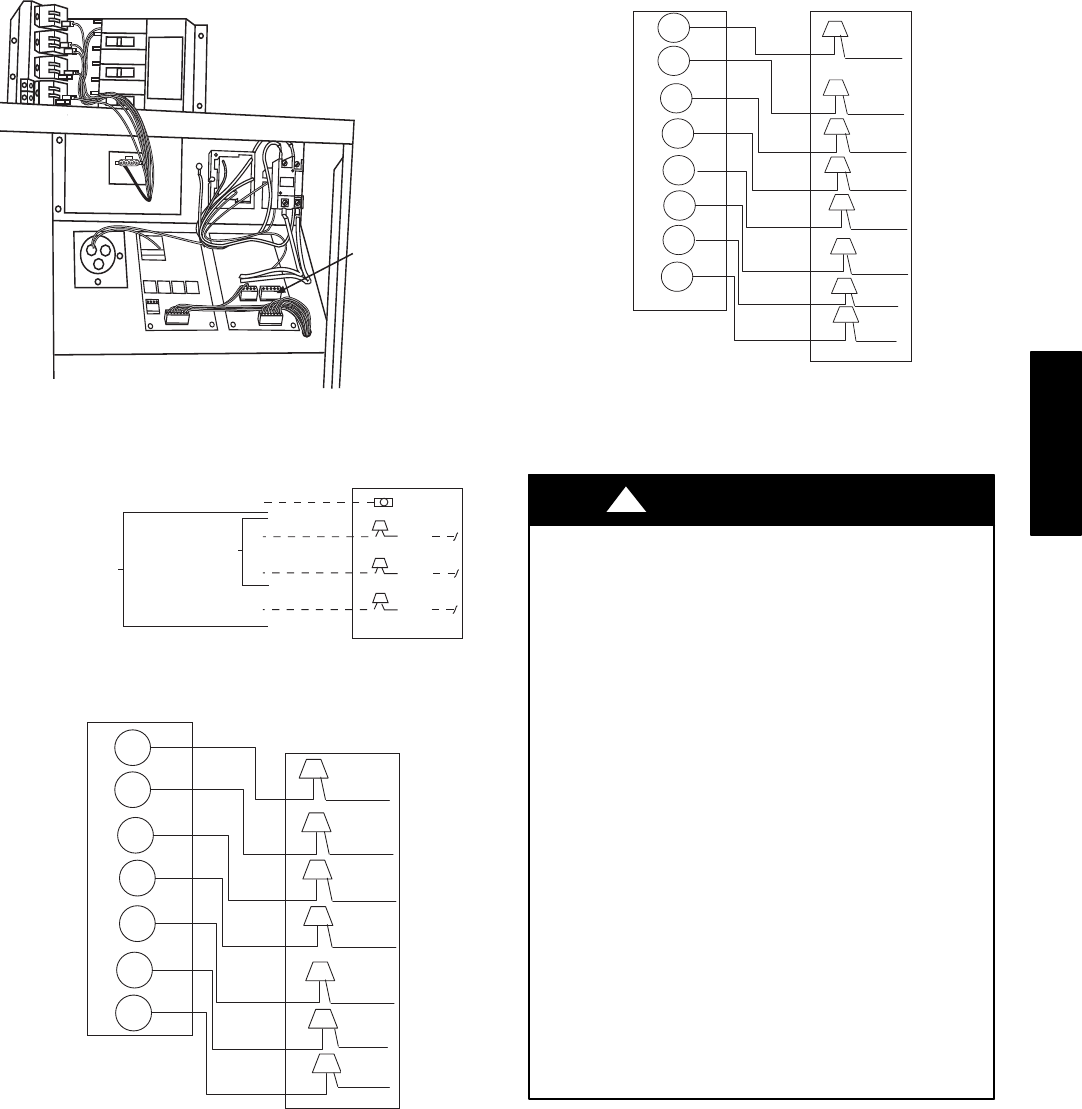

3-PHASE

CONNECTIONS

TO DISCONNECT

PER NEC

SINGLE-PHASE

CONNECTIONS

TO DISCONNECT

PER NEC

GROUND

LEAD

UNIT GROUND

BLK

YEL

BLU

L

L

L

C00012

Fig. 9 -- Line Power Connections

Thermostat

Unit Control

G

Y

W2

W3

R

RED

GRN

YEL

O

ORN

C

BRN

WHT

VIO

and subbase

Power

A05207

Fig. 10 -- Control Connections (Sizes 024 --042)

Thermostat

Unit Control

G

Y

Y1

O

R

RED

GRN

YEL

W2

PNK

W3

ORN

WHT

VIO

C

BRN

Power

and subbase

A05208

Fig. 11 -- Control Connections (Sizes 048--060)

PRE--START--UP

FIRE, EXPLOSION, ELECTRICAL SHOCK

HAZARD

Failure to follow this warning could result in personal

injury or death and/or property damage.

1. Follow recognized safety practices and wear protective

goggles when checking or servicing refrigerant system.

2. Relieve and recover all refrigerant from system before

touching or disturbing anything inside terminal box if

refrigerant leak is suspected around compressor

terminals.

3. Never attempt to repair soldered connection while

refrigerant system is under pressure.

4. Do not use torch to remove any component. System

contains oil and refrigerant under pressure.

5. To remove a component, wear protective goggles and

proceed as follows:

a. Shut off electrical power to unit and install

lockout tag.

b. Relieve and reclaim all refrigerant from system

using both high-- and low--pressure ports.

c. Cut component connecting tubing with tubing

cutter and remove component from unit.

d. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to flame.

!

WARNING

Proceed as follows to inspect and prepare the unit f or initial

start--up:

1. Remove all access panels.

2. Read and follow instructions on all DANGER, WARNING,

CAUTION, and INFORMATION labels attached to, or

shipped with unit.

3. Make the following inspections:

a. Inspect for shipping and handling damages, such as

broken lines, loos e parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections and

on unit base. Detecting oil generally indicates a

refrigerant leak. Leak test all refrigerant tubing

connections using electronic leak detector, or

liquid-- soap solution. If a refrigerant leak is detected, see

Check for Refrigerant Leaks section.

664B