—9—

IV. STEP 4 — FIELD FABRICATE DUCTWORK

On vertical units, secure all ducts to roof curb and building

structure. Do not connect ductwork to unit. For horizontal

applications, field-supplied flanges should be attached to

horizontal discharge openings and all ductwork secured to

the flanges. Insulate and weatherproof all external duct-

work, joints, and roof openings with counter flashing and

mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return

should be ducted through the roof deck to comply with appli-

cable fire codes.

A minimum clearance is not required around ductwork. Cab-

inet return-air static pressure (a negative condition) shall

not exceed 0.35 in. wg with economizer or 0.45 in. wg with-

out economizer.

These units are designed for a minimum continuous return-

air temperature in heating of 50 F (dry bulb), or an intermit-

tent operation down to 45 F (dry bulb), such as when used

with a night set-back thermostat.

To operate at lower return-air temperatures, a field-supplied

outdoor-air temperature control must be used to initiate both

stages of heat when the temperature is below 45 F. Indoor

comfort may be compromised when these lower air tempera-

tures are used with insufficient heating temperature rise.

V. STEP 5 — MAKE UNIT DUCT CONNECTIONS

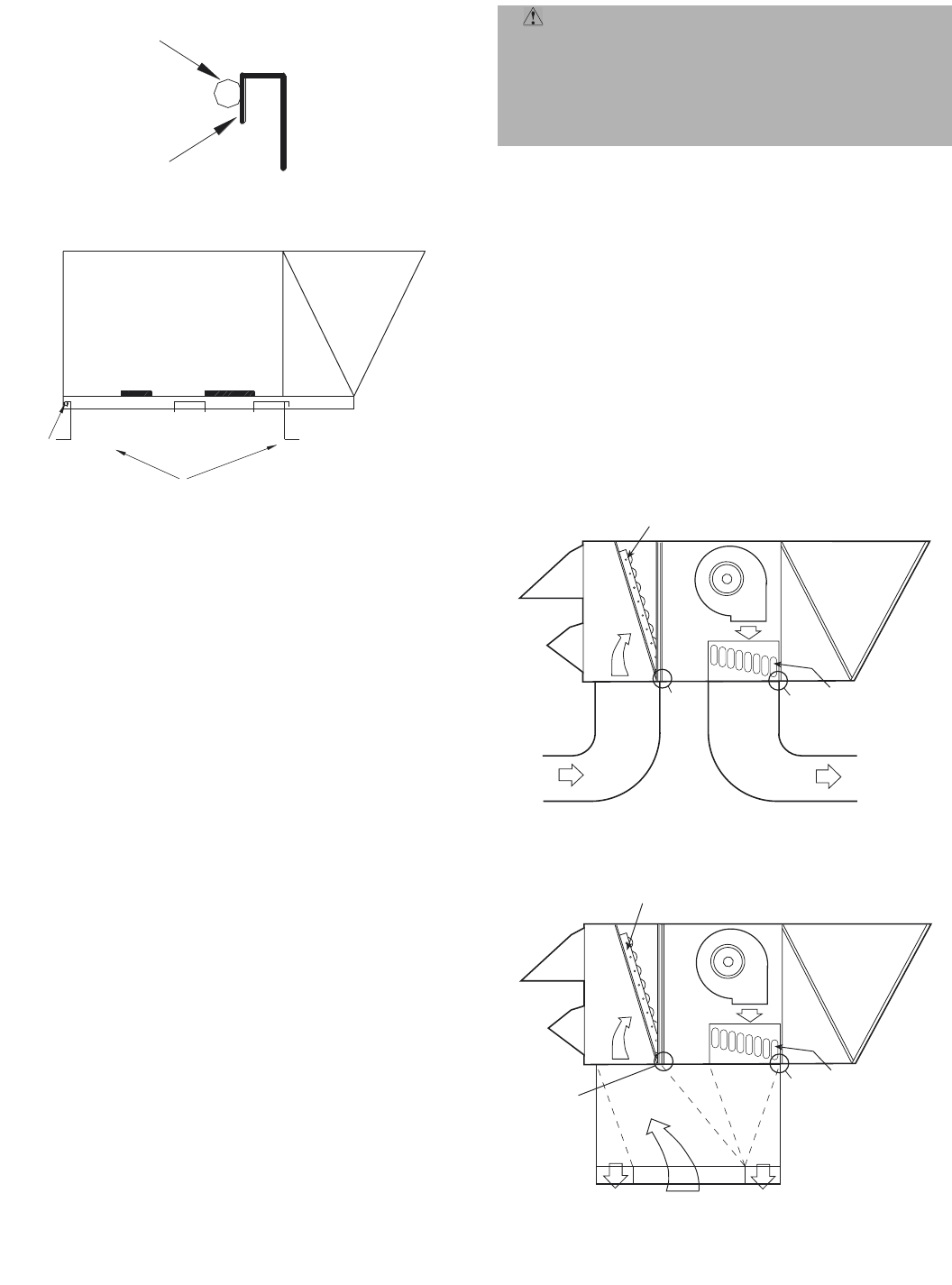

A. Vertical Configuration

Unit is shipped for vertical supply and return duct connec-

tions. Ductwork openings are shown in Fig. 1 and 4. Duct

connections for vertical configuration are shown in Fig. 7.

Field-fabricated concentric ductwork may be connected as

shown in Fig. 8 and 9. The unit is designed to attach the

ductwork to the roof curb. Do not attach duct directly to the

unit.

B. Horizontal Applications

Horizontal units are shipped with outer panels that allow for

side by side horizontal duct connections. If specified during

ordering, the unit will be shipped with the vertical duct

openings blocked off from the factory, ready for side supply

installation. If the horizontal supply/return option was not

specified at time of ordering the unit, a field-installed acces-

sory kit is required to convert the vertical unit into a hori-

zontal supply configuration.

Installation of the duct block-off covers should be completed

prior to placing the unit unless sufficient side clearance is

available. A minimum of 66 in. is required between the unit

and any obstruction to install the duct block-off covers. Side

supply duct dimensions and locations are shown on Fig. 4.

Install ductwork to horizontal duct flange connections on

side of unit.

WARNING: For vertical supply and return units,

tools or parts could drop into ductwork and cause an

injury. Install a 90-degree turn in the return ductwork

between the unit and the conditioned space. If a

90-degree elbow cannot be installed, then a grille of

sufficient strength and density should be installed to

prevent objects from falling into the conditioned space.

ALIGNMENT

HOLE SHOULD

LINE UP WITH

ROOF CURB

EDGE FLANGE

EDGE FLANGE

ALIGNMENT

HOLE

(IN BASE RAIL)

Fig. 5 — Alignment Hole Details

SUPPLY

OPENING

RETURN

OPENING

ROOF CURB

CURB

SUPPLY

OPENING

CURB

RETURN

OPENING

ALIGNMENT

HOLES FOR

CURB-BOTH

SIDES

Fig. 6 — Alignment Hole Location

SEE

NOTE

SEE

NOTE

AIR

OUT

AIR

IN

HEAT

EXCHANGER

ECONOMIZER

SEE

NOTE

SEE

NOTE

AIR OUT

AIR IN

HEAT

EXCHANGER

AIR OUT

ECONOMIZER

NOTE: Do not drill in this area; damage to basepan may result in wate

r

leak.

Fig. 7 — Air Distribution — Vertical Supply/Return

NOTE: Do not drill in this area; damage to basepan may result in water

leak.

Fig. 8 — Air Distribution — Concentric Duct