—10—

VI. STEP 6 — INSTALL FLUE HOOD AND INLET HOOD

Flue hood (smaller hood), inlet hood (larger hood), and

screens are shipped inside the unit in the fan section. To

install, remove the heat panel. The flue hood is attached to

the heat section panel from the outside using the screws pro-

vided. See Fig. 10.

The inlet hood is installed by inserting the hood through the

back of the heat panel. Attach the hood by inserting the

screws provided through the clearance holes in the heat

panel and into the intake hood.

Install the screens into both hoods using the screws and

retaining nuts provided with the unit.

Attach the cover of the observation hole on the intake hood

and then replace the heat panel onto the unit to complete the

installation.

NOTE: When properly installed, the flue hood will line up

with the combustion fan housing. See Fig. 11.

VII. STEP 7 — TRAP CONDENSATE DRAIN

See Fig. 12 for drain location. One

3

/

4

-in. half coupling is pro-

vided outside unit evaporator section for condensate drain

connection. A trap at least 4-in. deep must be used. See

Fig. 13.

All units must have an external trap for condensate drain-

age. Install a trap at least 4 in. deep and protect against

freeze-up. If drain line is installed downstream from the

external trap, pitch the line away from the unit at 1 in. per

10 ft of run. Do not use a pipe size smaller than the unit

connection.

VIII. STEP 8 — INSTALL GAS PIPING

Unit is equipped for use with natural gas. Refer to local

building codes, or in the absence of local codes, to ANSI

(American National Standards Institute) Z223.1-latest year

and addendum Z223.1A-latest year entitled NFGC. In Can-

ada, installation must be in accordance with the

CAN1.B149.1 and CAN1.B149.2 installation codes for gas

burning appliances.

Support gas piping. For example, a

3

/

4

-in. gas pipe must have

one field-fabricated support beam every 8 ft. Therefore, an

18-ft long gas pipe would have a minimum of 3 support

beams.

Install field-supplied manual gas shutoff valve with a

1

/

8

-in. NPT pressure tap for test gage connection at unit. The

pressure tap is located on the gas manifold, adjacent to the

gas valve. Field gas piping must include sediment trap and

union. See Fig. 14.

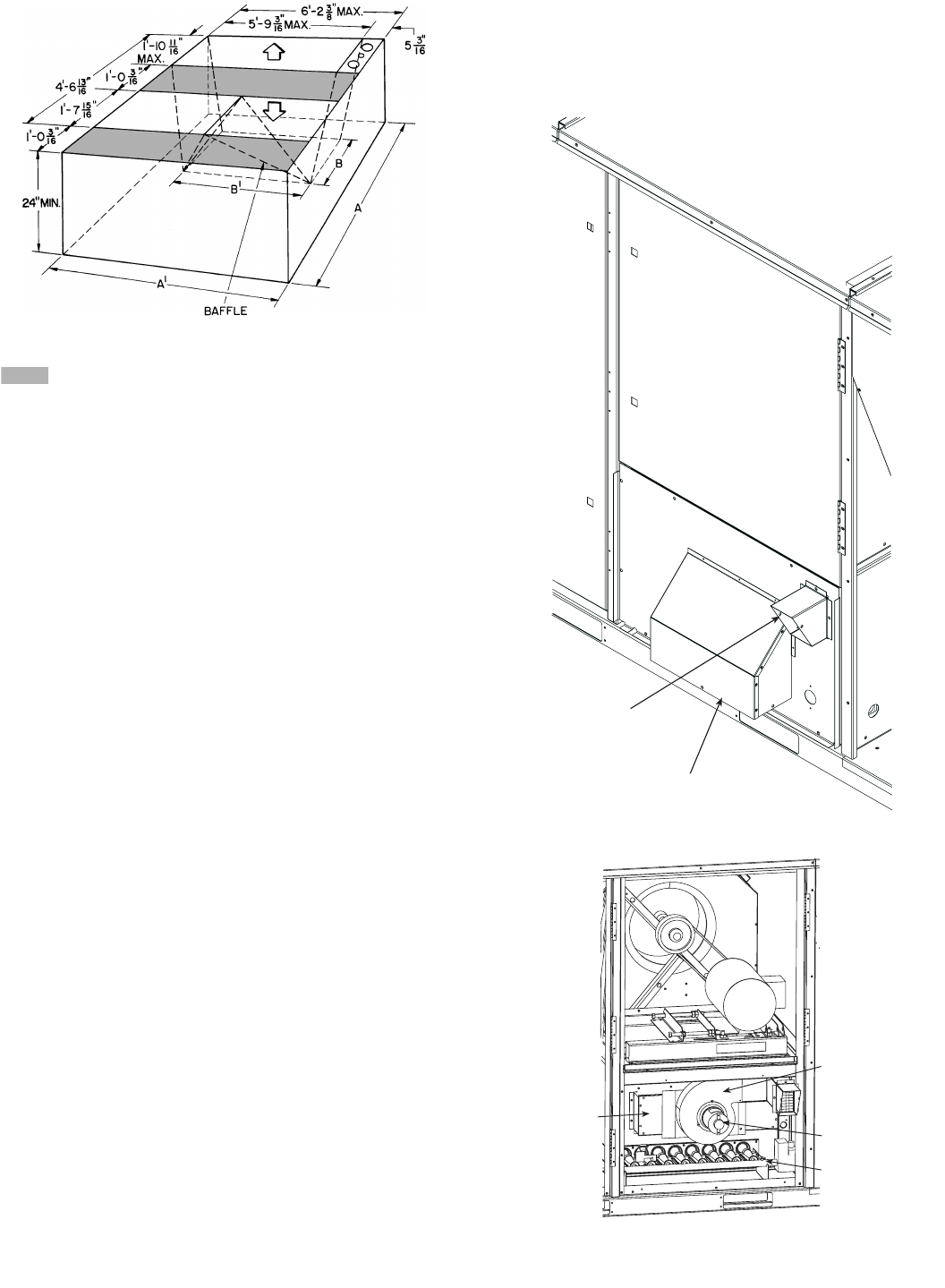

NOTE: Dimensions A, A′, B, and B′ are obtained from field-supplied

ceiling diffuser.

Shaded areas indicate block-off pans.

Fig. 9 — Concentric Duct Details

FLUE HOOD

INLET HOOD

Fig. 10 — Flue and Inlet Hood Locations

MAIN BURNER

SECTION

INDUCED-DRAFT

MOTOR

COMBUSTION

FAN HOUSING

HEAT

EXCHANGER

SECTION

Fig. 11 — Combustion Fan Housing Location