B. CONVERTING HORIZONTAL DISCHARGE UNITS TO

DOWNFLOW (Vertical) DISCHARGE

WARNING: Before performing service or maintenance

operations on system, turn off main power to unit. Turn

off accessory heater power switch if applicable. Electrical

shock can cause serious injury or death.

Units are dedicated side supply products. They are not convertible

to vertical air supply. A field-supplied plenum must be used to

convert to vertical air discharge.

VI. PROVIDE FOR CONDENSATE DISPOSAL

NOTE: Be sure that condensate-water disposal methods comply

with local codes, restrictions, and practices.

Unit removes condensate through a 1-3/64-in. ID hole which is

located at the end of the unit. See Fig. 2-4 for location of

condensate connection.

Condensate water can be drained directly onto the roof in rooftop

installations (where permitted) or onto a gravel apron in ground-

level installations. Install a field-supplied condensate trap at end of

condensate connection to ensure proper drainage. Make sure that

the outlet of the trap is at least 1 in. lower than the drain-pan

condensate connection to prevent the pan from overflowing. See

Fig. 9A and 9B. Prime the trap with water. When using a gravel

apron, make sure it slopes away from the unit.

If the installation requires draining the condensate water away

from the unit, install a 2-in. trap using a 3/4-in. OD tube or pipe.

See Fig. 9A and 9B. Make sure that the outlet of the trap is at least

1 in. lower than the unit drain-pan condensate connection to

prevent the pan from overflowing. Prime the trap with water.

Connect a drain tube using a minimum of 3/4-in. PVC, 3/4-in.

CPVC, or 3/4-in. copper pipe (all field supplied). Do not undersize

the tube. Pitch the drain tube downward at a slope of at least 1 in.

for every 10 ft of horizontal run. Be sure to check the drain tube

for leaks. Prime trap at the beginning of the cooling season

start-up. Allowable glues for condensate trap connection are:

Standard ABS, CPVC, or PVC cement.

VII. INSTALL ELECTRICAL CONNECTIONS

WARNING: The unit cabinet must have an uninter-

rupted, unbroken electrical ground to minimize the pos-

sibility of personal injury if an electrical fault should

occur. This ground may consist of an electrical wire

connected to the unit ground in the control compartment,

or conduit approved for electrical ground when installed

in accordance with NEC (National Electrical Code),

ANSI (American National Standards Institute)/NFPA

(latest edition) (in Canada, Canadian Electrical Code

CSA C22.1) and local electrical codes. Failure to adhere

to this warning could result in serious injury or death.

Fig. 5—Shipping Location of Duct Flanges

(Size 060 Only)

C00005

FIVE PIECES OF DUCT

FLANGE ATTACHED

HERE FOR SHIPMENT

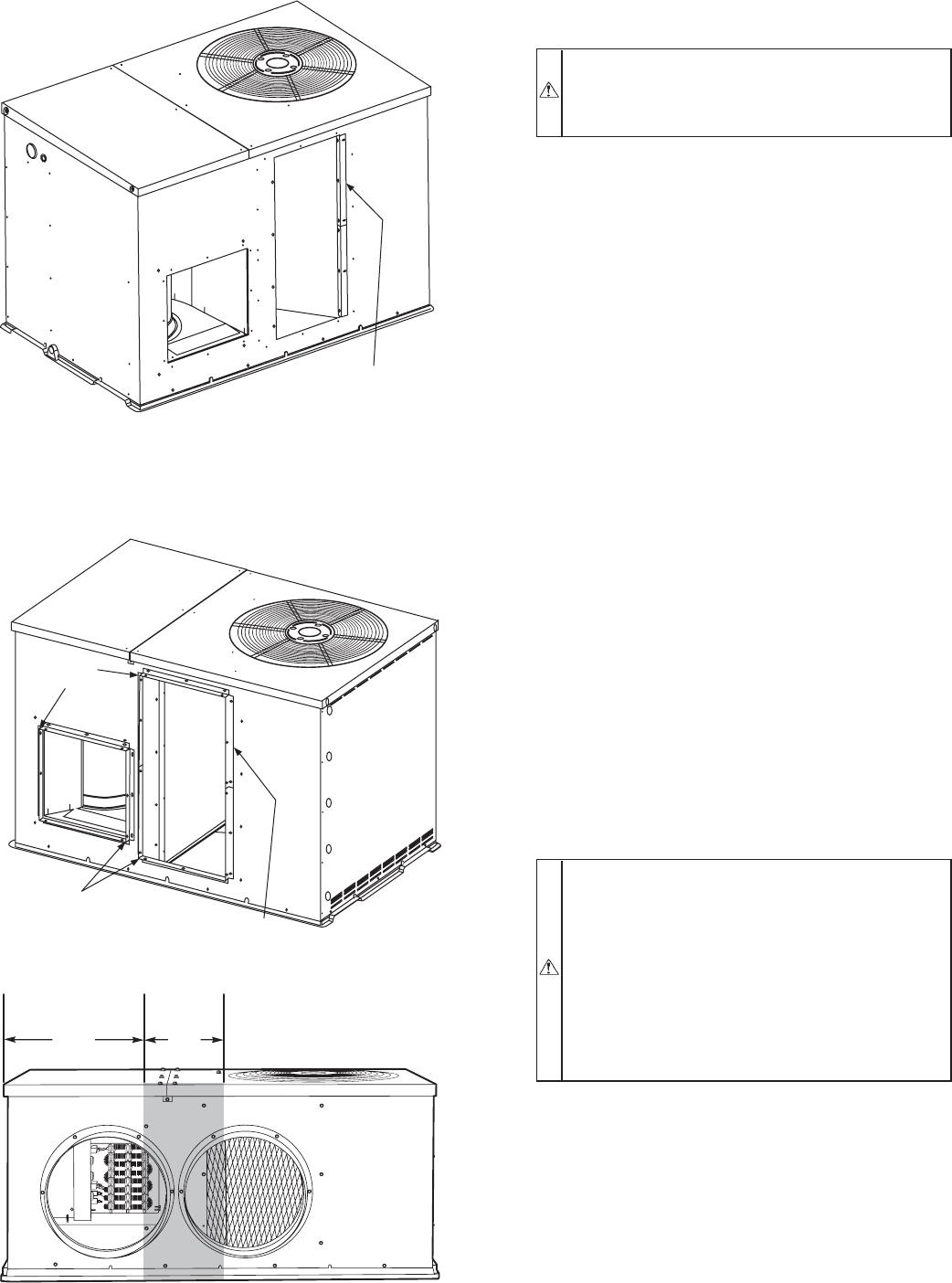

Fig. 6—Flanges Installed on 564A060 Units

C00006

HAND

FORM

HAND FORM

STRAIGHT PIECE

Fig. 7—Area Not to Be Drilled More Than 3/4-in.

C00007

19.17″ 3.92″

—6—