—13—

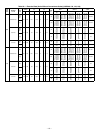

Table 2B — Electrical Data (Units Without Convenience Outlet) (558F091, 103, 121, 151)

LEGEND

*Used to determine minimum disconnect per NEC.

†Fuse or HACR circuit breaker per NEC.

**Fuse only.

††Compressor no. 1 is shown in table.

208/230-3-60: Compressor no. 2 RLA is 14.1 amps and LRA is 105 amps.

460-3-60: Compressor no. 2 RLA is 7.1 amps and LRA is 55 amps.

575-3-60: Compressor no. 2 RLA is 6.4 amps and LRA is 40 amps.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load equipment (refer to NEC

Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or HACR breaker.

Canadian units may be fuse or circuit breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

Use the

following formula to determine the percent of voltage imbalance.

% Voltage Imbalance

Example: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

= 457

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent of voltage imbalance.

= 1.53%

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electric utility

company immediately.

3. For units with power exhaust: If a single power source is to be used, size wire to include power

exhaust MCA and MOCP. Check MCA and MOCP when power exhaust is powered through the

unit (must be in accordance with NEC and/or local codes). Determine the new MCA including the

power exhaust using the following formula:

MCA New = MCA unit only + MCA of Power Exhaust

For example, using a 558FPX091000 unit with MCA = 40.1 and MOCP = 45, with

CRPWREXH030A01 power exhaust.

MCA New = 40.1 amps + 1.6 amps = 41.7 amps

If the new MCA does not exceed the published MOCP, then MOCP would not change. The MOCP

in this example is 45 amps, the MCA New is below 45, therefore the MOCP is acceptable. If “MCA

New” is larger than the published MOCP, raise the MOCP to the next larger size. For separate

power, the MOCP for the power exhaust will be 15 amps per NEC.

4. Determine heater capacity using multiplication factors table below:

NOTE: The following equation converts kW of heat energy to Btuh: kW x 3.412 = Btuh.

EXAMPLE: 32.0 kW (at 240 v) heater on 208 v

= 32.0 (.751 mult factor)

= 24.0 kW capacity at 208 v

558F

UNIT

SIZE

NOMINAL

V-PH-Hz

IFM

TYPE

VOLTAGE

RANGE

COMPRESSOR

(ea)

OFM (ea)

IFM

FLA

HEATER

MODEL NO.

CRHEATER---A00

ELECTRIC HEAT POWER SUPPLY

DISCONNECT

SIZE*

SINGLE POINT

BOX P/N

CRSINGLE---A00

Min Max Qty RLA LRA Qty Hp FLA

Nominal

kW

FLA MCA MOCP† FLA LRA

091

208/230-3-60

STD

187 254 2 14 91 2

1

/

4

1.4

5.8

NONE

—/— —/— 40.1/ 40.1 45/ 45 42/ 42 229/229 —

017 7.8/10.4 21.7/ 25.0 40.1/ 40.1 45/ 45 42/ 42 229/229 006

010 12.0/16.0 33.4/ 38.5 48.9/ 55.4 50/ 60 45/ 51 229/229 006

011 18.4/24.8 51.7/ 59.7 71.9/ 81.8 80/ 90** 66/ 75 229/229 007

012 24.0/32.0 66.7/ 77.0 90.6/103.5 100/110** 83/ 95 229/229 007

012 and 017 31.8/42.4 88.4/102.0 117.7/134.8 125/150** 108/124 229/229 009

ALT 5.8

NONE —/— —/— 40.1/ 40.1 45/ 45 42/ 42 229/229 —

017 7.8/10.4 21.7/ 25.0 40.1/ 40.1 45/ 45 42/ 42 229/229 006

010 12.0/16.0 33.4/ 38.5 48.9/ 55.4 50/ 60 45/ 51 229/229 006

011 18.6/24.8 51.7/ 59.7 71.9/ 81.8 80/ 90** 66/ 75 229/229 006

012 24.0/32.0 66.7/ 77.0 90.6/103.5 100/110** 83/ 95 229/229 007

012 and 017 31.8/42.4 88.4/102.0 117.7/134.8 125/150** 108/124 229/229 009

HIGH 10.6

NONE —/— —/— 44.9/ 44.9 50/ 50 48/ 48 273/273 —

017 7.8/10.4 21.7/ 25.0 44.9/ 44.9 50/ 50 48/ 48 273/273 006

010 12.0/16.0 33.4/ 38.5 54.9/ 61.4 60/ 70** 51/ 56 273/273 007

011 18.6/24.8 51.7/ 59.7 77.9/ 87.8 80/ 90** 72/ 81 273/273 007

012 24.0/32.0 66.7/ 77.0 96.6/109.5 100/110** 89/101 273/273 007

012 and 017 32.3/42.4 88.4/102.0 123.7/140.8 125/150** 114/129 273/273 009

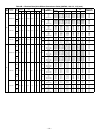

460-3-60

STD

414 508 2 6.4 42 2

1

/

4

0.7

2.6

NONE — — 18.4 20 19 108 —

016 13.9 16.7 24.1 25 22 108 006

013 16.5 19.8 28.1 30 26 108 006

014 27.8 33.4 45.0 50 41 108 006

015 33.0 39.7 52.9 60 49 108 006

014 and 016 41.7 50.2 65.9 70** 61 108 008

ALT 2.6

NONE — — 18.4 20 19 108 —

016 13.9 16.7 24.1 25 22 108 006

013 16.5 19.8 28.1 30 26 108 006

014 27.8 33.4 45.0 50 41 108 006

015 33.0 39.7 52.9 60 49 108 006

014 and 016 41.7 50.2 65.9 70** 61 108 008

HIGH 4.8

NONE — — 20.6 25 22 130 —

016 13.9 16.7 26.9 30 25 130 006

013 16.5 19.8 30.8 35 28 130 006

014 27.8 33.4 47.8 50 44 130 006

015 33.0 39.7 55.6 60 51 130 006

014 and 016 41.7 50.2 68.7 70** 63 110 008

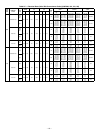

575-3-60

STD

518 632 2 5.2 39 2

1

/

4

0.7

2.6

NONE — — 14.9 20 16 97 —

018 17.0 17.1 23.9 25 22 97 006

019 34.0 34.1 45.3 40 42 97 006

ALT 2.6

NONE — — 14.9 20 16 97 —

018 17.0 17.1 23.9 25 22 97 006

019 34.0 34.1 45.3 40 42 97 006

HIGH 4.8

NONE — — 16.7 20 18 114 —

018 17.0 17.1 26.1 30 24 114 006

019 34.0 34.1 47.5 45 44 114 006

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

= 100 x

max voltage deviation from average voltage

average voltage

Average Voltage =

452 + 464 + 455

3

=

1371

3

% Voltage Imbalance = 100 x

7

457

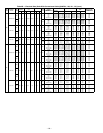

POWER EXHAUST

PART NO.

MCA

(230 v)

MCA

(460 v)

MCA

(575 v)

MOCP

(for separate

power source)

CRPWREXH021A01 N/A 0.9 N/A 15

CRPWREXH022A01 3.3 N/A 1.32 15

CRPWREXH023A01 N/A 1.8 N/A 15

CRPWREXH028A01 1.7 N/A 0.68 15

CRPWREXH029A01 N/A 1.0 N/A 15

CRPWREXH030A01 1.6 N/A 0.64 15

HEATER

RATING

VOLTAGE

ACTUAL HEATER VOLTAGE

200 208 230 240 380 440 460 480 550 575 600

240 0.694 0.751 0.918 1.000 — — — — — — —

480 — — — — 0.626 0.840 0.918 1.000 — — —

600 — — — — — — — — 0.840 0.918 1.000