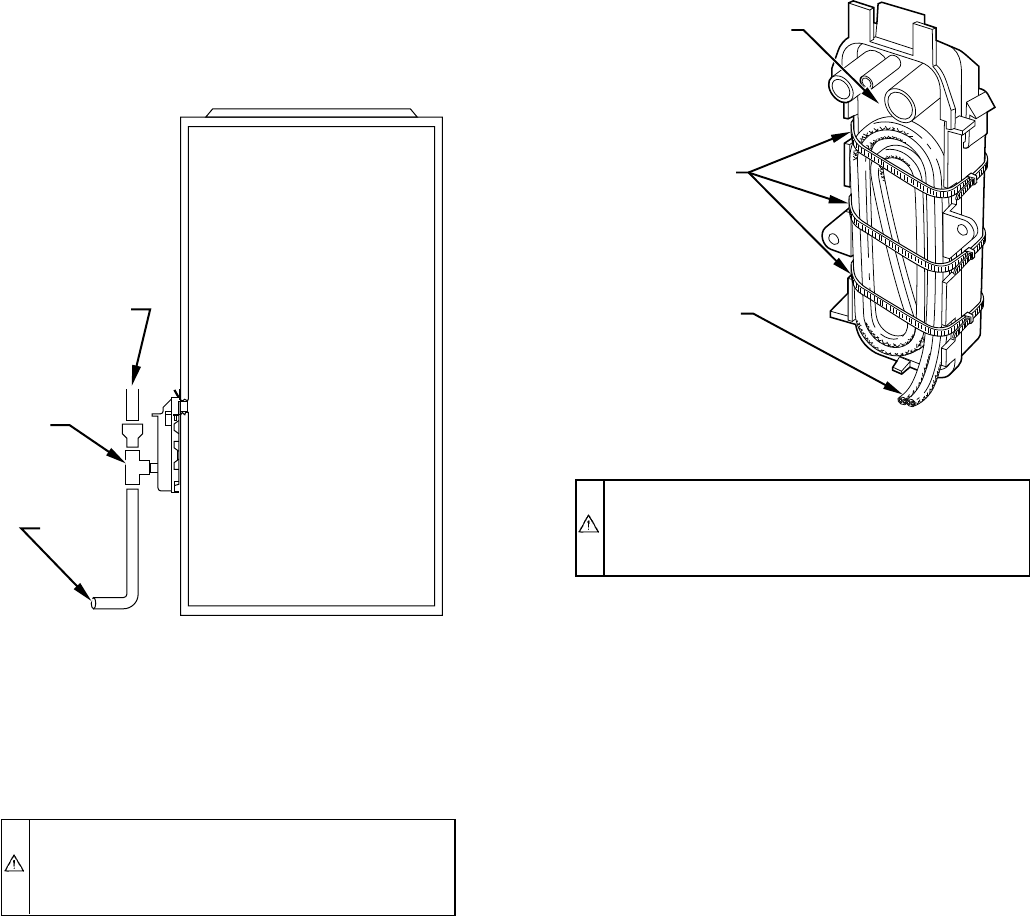

See Fig. 40 for example of possible field drain attachment using

1/2-in. CPVC or PVC tee for vent and A/C or humidifier drain

connection.

Outdoor draining of the furnace is permissible if allowed by local

codes. Caution should be taken when freezing ambient may freeze

drain pipe and prohibit draining.

WARNING: Caution should be taken to prevent drain-

ing where slippery conditions may cause personal inju-

ries. Excessive condensate draining may cause saturated

soil conditions which may result in damage to plants.

III. CONDENSATE DRAIN PROTECTION

Freezing condensate left in condensate trap and drain line may

cause cracks, and possible water damage may occur. If freeze

protection is required, use condensate freeze protection accessory

or equivalent 3 to 6 watt per ft at 120v and 40°F self-regulating,

shielded, and waterproof heat tape. See Installation Instructions

supplied with accessory or heat tape manufacturer’s recommenda-

tions.

1. Fold heat tape in half and wrap on itself 3 times.

2. Locate heat tape between sides of condensate trap back.

(See Fig. 41.)

3. Use wire ties to secure heat tape in place. Wire ties can be

positioned in notches of condensate trap sides. (See Fig.

41.)

4. Wrap field drain pipe with remaining heat tape, approxi-

mately 1 wrap per ft.

5. When using field-supplied heat tape, follow heat tape

manufacturer’s instructions for all other installation guide-

lines.

SEQUENCE OF OPERATION

CAUTION: Furnace control must be grounded for

proper operation, or control will lock out. Control is

grounded through green wire routed to gas valve and

burner box screw.

Using schematic diagram, follow sequence of operation through

different modes. (See Fig. 24.) Read and follow wiring diagram

carefully.

NOTE: If 115-v power supply to furnace or blower access panel

switch is interrupted during a call for heat, blower operates for 90

sec when power is restored before heating cycle is resumed.

I. HEATING MODE

When wall thermostat calls for heat, R-W circuit closes. Furnace

control performs a self-check, verifies pressure switch contacts are

open, and starts inducer motor.

1. Prepurge period—As inducer motor comes up to speed,

pressure switch contacts close to begin a 15-sec prepurge

period.

2. Ignitor warm up—At end of prepurge period, ignitor is

energized for a 17-sec ignitor warm-up period.

3. Ignition sequence—When ignitor warm-up period is com-

pleted, gas valve opens, permitting gas flow to burners

where it is ignited. After 5 sec, ignitor is de-energized and

a 2-sec flame-sensing period begins.

HUM terminal on control center is energized with gas

valve. See Accessories — Humidifier section.

4. Flame sensing—When burner flame is sensed, control

begins blower on delay period and continues holding gas

valve open.

If burner flame is not sensed, control center de-energizes

gas valve and ignition sequence is repeated.

NOTE: Ignition sequence repeats 3 additional times before a

lockout occurs. Lockout automatically resets after 3 hr or can be

manually reset by turning off 115v (not at thermostat) for 3 sec

minimum, then turning it on again.

5. Blower on delay—Sixty sec after burner flame is proven

(40 sec if jumper has been cut for 140 size unit in downflow

orientation), blower motor is energized on heating speed.

Simultaneously, electronic air cleaner terminal EAC-1 is

energized.

Fig. 40—Example of Field Drain Attachment

A94054

OPEN STAND

PIPE FOR

A/C OR

HUMIDIFIER

DRAIN

TEE

TO OPEN

DRAIN

Fig. 41—Condensate Trap Heat Tape

A93036

CONDENSATE TRAP

WIRE TIE(S)

HEAT TAPE

(3 WRAPS MINIMUM)

—31—

→