18

Fuel connection to nozzle line assembly is secure.

Dimension Z has been set per the ‘Set Z

Dimension’ instructions detailed earlier in this

manual. The acorn nut (Figure 7, item C) should

never be loosened once the Z dimension is initially

set.

Fuel supply line is correctly installed, the oil tank is

suffi ciently fi lled, and shut-off valves are open.

Burner is securely mounted in appliance, with

pressure fi ring plate and gasket installed for

pressurized chamber application.

Appliance has been fi lled with water (boilers) and

controls have been operationally checked.

Burner has been installed in accordance with

appliance manufacturer’s instructions (when

available).

Also refer to appliance manufacturer’s instructions

(when available) for start-up procedures.

Initial head position (Figure 7)

The indicator plate assembly markings

correspond to head position settings.

Loosen the fastener (Figure 7, item d) and

slide the indicator plate until the number on the

indicator plate corresponds to the initial head

setting listed in Table 7, for the desired fi ring

rate.

When the head position has been set, tighten

the fastener and the spline nut.

□

□

□

□

□

□

□

□

○

○

○

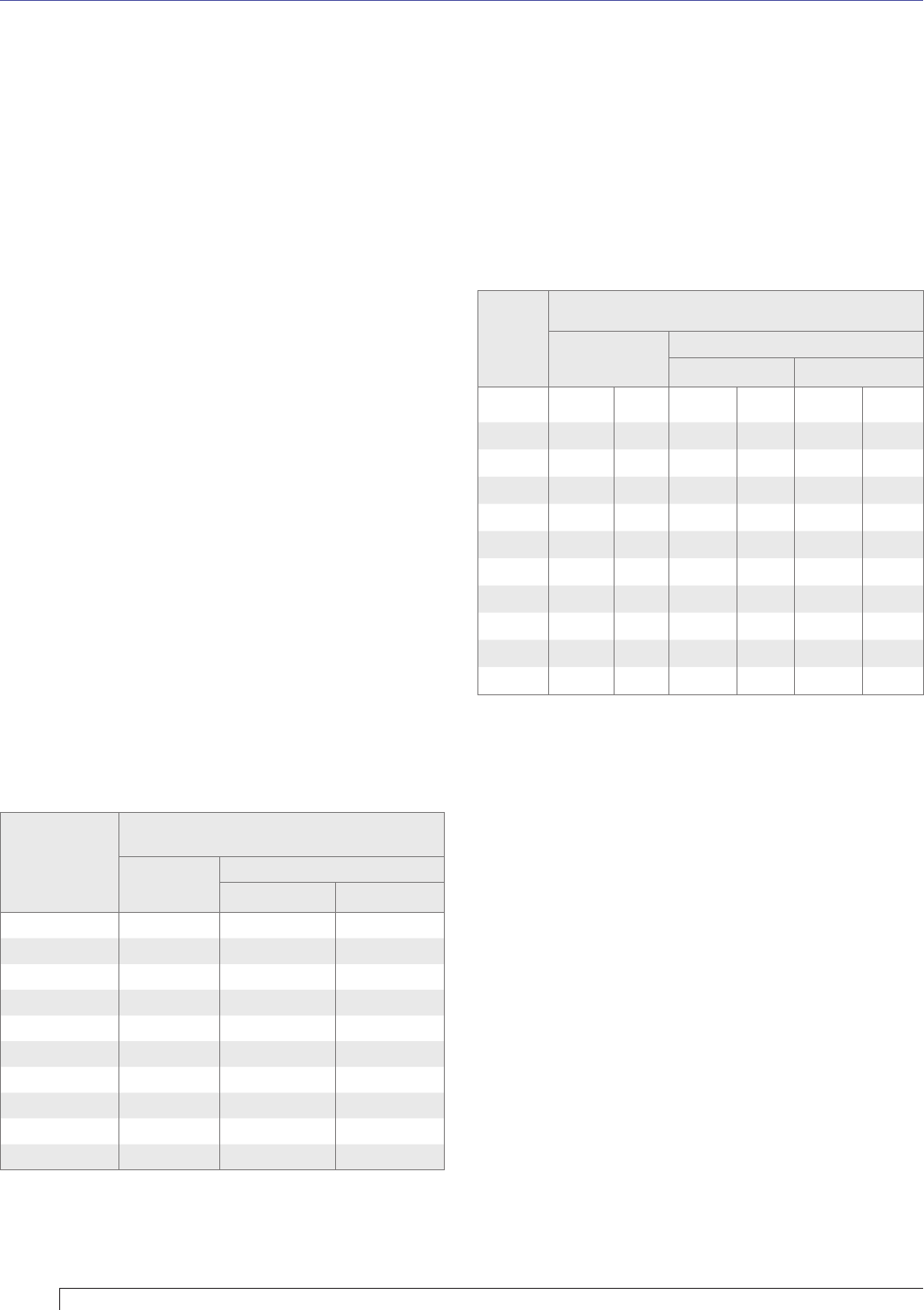

Table 8 - Initial air shutter and band settings

Rate

GPH

Approximate air settings

CF500

CF800

Tube A Tube B

Shutter Band Shutter Band Shutter Band

1.75 1 0 -- -- -- --

2.25 2 0 -- -- -- --

3.00 10 1 1 0 -- --

3.50 10 2 3 0 -- --

4.00 10 3 4 0 -- --

5.00 10 5 9 0 8 2

5.50 10 10 9 5 9 4

6.00 -- -- 10 3 10 3

7.00 -- -- 10 8 10 5

8.00 -- -- -- -- 10 10

Note: These settings are appoximate, and can vary depending on

actual job conditions and overfi re pressure

Table 7 - Initial indicator adjustment plate settings

(head position)

Rate GPH

Approximate head settings

CF500

CF800

Tube A Tube B

1.75 0 -- --

2.25 0

3.00 4 0 --

3.50 5 1 --

4.00 5 2 --

5.00 6 4 3

5.50 6 4 4

6.00 -- 4 4

7.00 -- 6 5

8.00 -- -- 6

Initial air settings (Table 8)

Loosen the air band and shutter, and adjust to the

approximate fi ring rate settings given in Table 8.

These initial settings should be adequate for starting

the burner. Once the burner is in operation, the air

settings will be adjusted for best performance as

discussed later in this manual.

Follow the procedures described later in this manual

for fi ne-tuning the air settings.

○

○

○

Set appliance limit controls

Set the appliance limit controls in accordance with the

appliance manufacturer’s recommendations.

Prepare the fuel unit for air venting

To vent air from the oil supply line, attach a clear

hose to the pump air bleed valve (Figures 8 & 9)

on the fuel unit. Provide a container to catch the oil.

Loosen the pump air bleed valve.

Vent the air as described in the next section under

Start the burner.

○

○

Section: Prepare the Burner for Start-up