Manual 2100-467K

Page 18 of 24

LOW PRESSURE SWITCH, BYPASS, AND

LOCKOUT SEQUENCE (Standard Feature)

If the low pressure switch opens for more that 120

seconds, the compressor contactor will de-energize

and go into a soft lockout. Regardless the state of the

low pressure switch, the contactor will reenergize after

the delay-on-make time delay has expired. If the low

pressure switch remains open or opens again for longer

than 120 seconds the unit will go into manual lockout

condition and the alarm circuit will energize. Recycling

the wall thermostat resets the manual lockout.

ALARM OUTPUT

Alarm terminal is output connection for applications

where alarm signal is desired. This terminal is powered

whenever compressor is locked out due to HPC or LPC

sequences as described.

NOTE: Both high and low pressure switch controls

are inherently automatic reset devices. The

high pressure switch and low pressure switch

cut out and cut in settings are xed by specic

air conditioner or heat pump unit model. The

lockout features, both soft and manual, are a

function of the Compressor Control Module.

ADJUSTMENTS

ADJUSTABLE DELAY-ON-MAKE AND

D

ELAY-ON-BREAK TIMER

The potentiometer is used to select Delay-on-Break

time from 30 seconds to 5 minutes. Delay-on-

Make (DOM) timing on power-up and after power

interruptions is equal to 2 minutes plus 10% of Delay-

on-Break (DOB) setting:

0.5 minute (30 seconds) DOB = 123 second DOM

1.0 minute (60 seconds) DOB = 126 second DOM

2.0 minute (120 seconds) DOB = 132 second DOM

3.0 minute (160 seconds) DOB = 138 second DOM

4.0 minute (240 seconds) DOB = 144 second DOM

5.0 minute (300 seconds) DOB = 150 second DOM

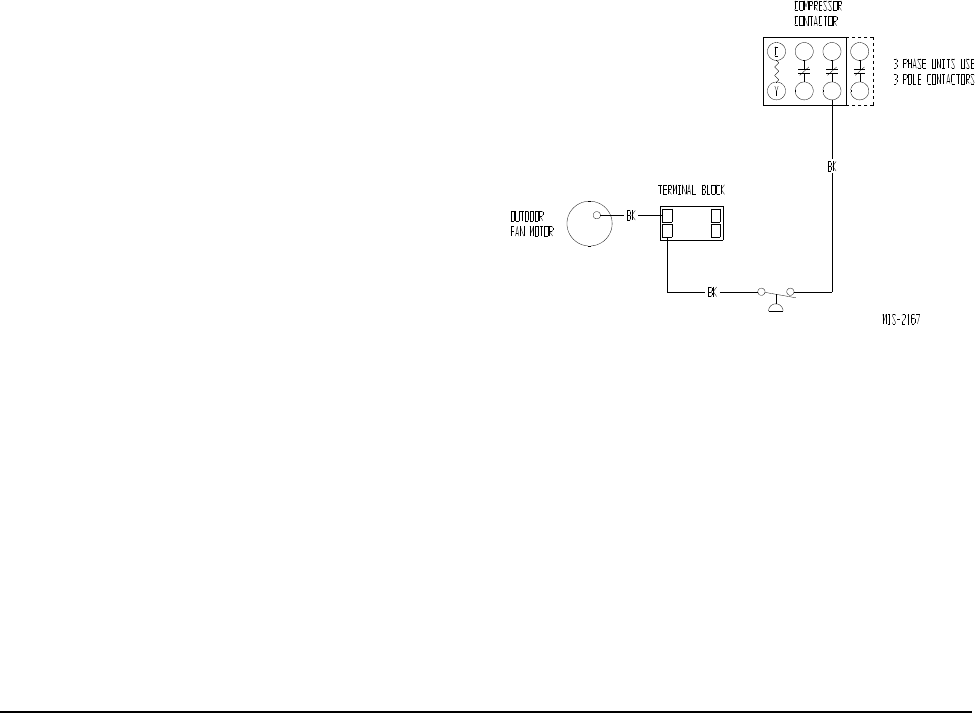

FIGURE 7

LOW AMBIENT CONTROL WIRING

LOW AMBIENT CONTROL

Optional Low Ambient Control

An optional low ambient control is available for both

factory and eld installed options. The low ambient

control is to be applied to the PA13 Series models when

operation below 55° outdoor conditions are anticipated.

Without this device, the evaporating pressure would fall

off, and the indoor coil would ice over.

The fan cycling control cycles the fan motor on, once

the liquid refrigerant pressure reaches 350 psig, and

off, once it has dropped to 225 psig. It will continue to

cycle between these parameters depending on outdoor

temperatures and the load/stage of the system.

This cycling maintains a minimum liquid pressure

affecting the minimum suction pressure. This effect

insures an evaporating temperature that is slightly above

the point of ice formation on the evaporator.

This eld installed option is Bard Part #CMA-28. See

Figure 7.