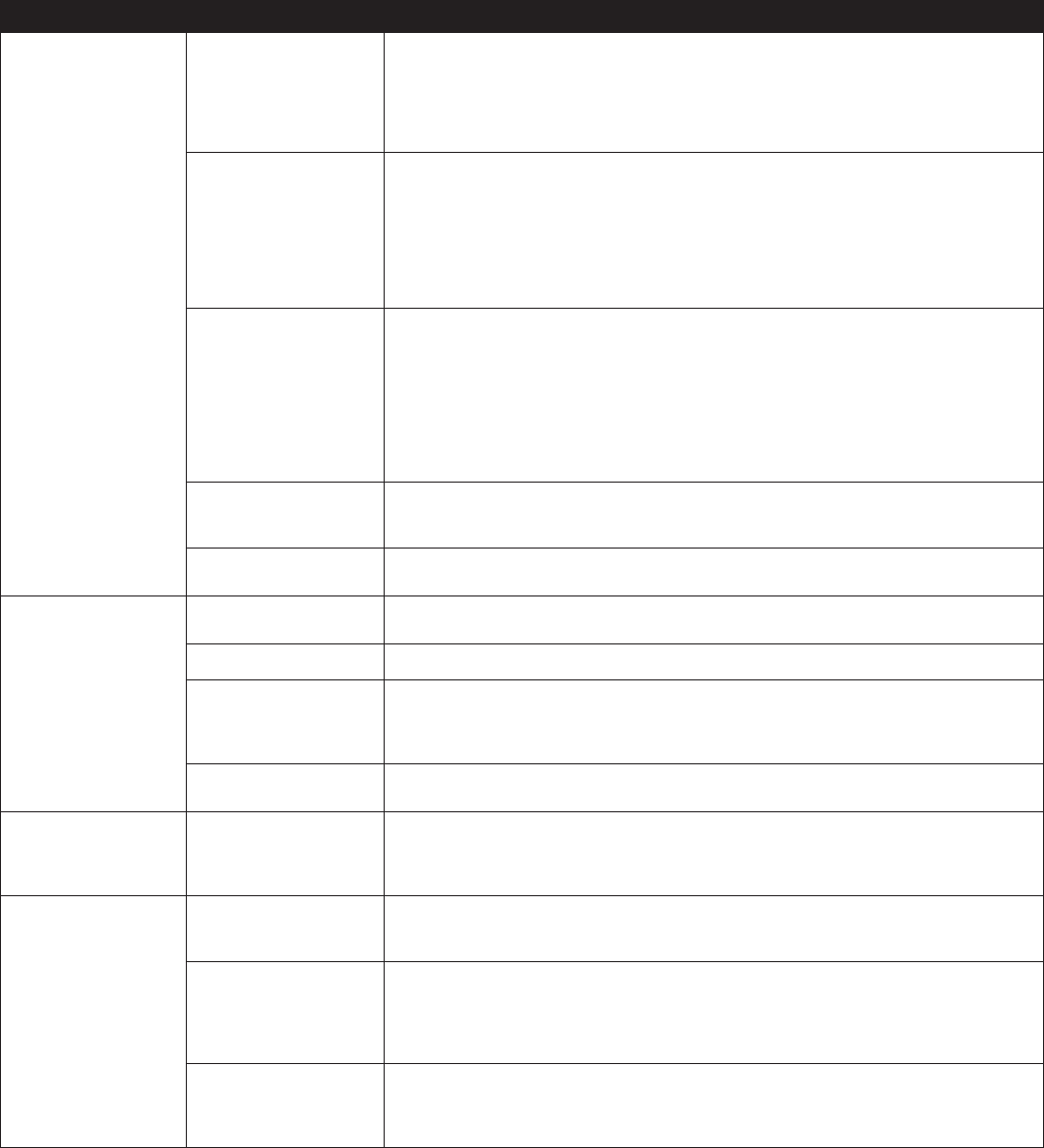

Problem Possible Cause Action

Humidity below

desired level

No humidity demand signal

from humidistat

• Low or no signal from humidistat. Check for proper wiring.

• No demand signal by others.

• If using Automatic Steam Humidifier Control in the Automatic Mode and the temperature

outside is greater than 60°F, the unit will not operate. If humidity is desired in those conditions,

run the Control in Manual Mode.

• If using Automatic Steam Humidifier Control, verify that the Control is not in Test Mode.

Unit is operating but fails

to meet required humidity

output

• If steam is passing to the plumbing system drain, the P-trap is not filled with water:

− Disconnect the probe assembly to allow the fill valve to overfill the chamber to fill the P-trap.

− If there is excessive internal steam pressure, determine the cause of the high pressure (e.g.,

high duct static pressure, undersized orifices in distribution tube) and repair as required.

• If drain valve does not close fully, determine the cause and clean, repair, or replace as needed.

• If fill valve is stuck open, repair or replace.

• Replace leaking gasket or vapor hose.

• Unit is undersized; replace with a larger unit or add additional humidifier.

Heating elements not

operating

• Verify that humidistat is calling for humidity.

• Check for control voltage if limit controls (airflow proving switch, etc.) are not allowing unit to

operate.

• Check power fuse. If open, replace fuse with equal fuse.

• Verify contactor and transformer electrical plugs are fully engaged.

• Check if the heater over-temperature switch has been tripped. Reset or replace if necessary.

• Check water conductivity. Water conductivity must be at least 100 µS/cm

2

. Add salt to increase.

• Check if the non-resettable over-temperature thermostats have tripped. Replace if necessary.

• If heaters are burned out, refer to “heater burnout” problem on page 34.

Humidity control input

type not the same as the

operating mode.

• Check the internal control board connections and slide switches S1 and S2 positions 1 and 2.

See pages 11-12 for more information.

Excessive outside air

volume

• Verify proper operation of fans and dampers.

Humidity above

set point

Improperly located

humidistat

• Relocate, using guidelines described on page 14.

Reduced airflow • Check fans and dampers.

Malfunctioning controls • Check for incorrect supply voltage.

• Check for incorrect control signal.

• Check for improper wiring hookup.

• Check if relay contactor shorted. Repair or replace as needed.

Improper slide switch

settings

• If the humidifier is receiving a 4-20 mA signal by others, the slide switches need to set as shown

on page 11 or the humidifier will run continuously.

Hunting (humidity

swings above and

below desired set

point)

Malfunctioning control

system

• If there is a faulty or inaccurate humidity controller, replace.

• Relocate improperly located control components. See humidity control placement information

on page 13.

Noisy operation

Thunder-type noise is

coming from chamber

during refill.

• This is normal on larger units and is caused by the cold fill water collapsing steam in the chamber.

Reduce water pressure (minimum of 25 psi [172 kPa]) if inlet water pressure is too high.

Contactor noise • Verify that contactor and transformer electrical plugs are fully engaged.

• Verify 24 VAC at H on internal control board and at C on terminal strip.

• Contactor normally makes a “clunk” sound as it pulls in. A continuous chattering noise is not

normal and is symptomatic of a failing contactor or malfunctioning controls. Replace contactor

or troubleshoot the control system.

Fill valve noise • A clicking sound as the fill valve opens or closes, and a hissing sound during fill are normal.

A slamming sound as fill valve closes is “water hammer” and can be minimized by installing

a shock arrestor.

• A loud buzzing sound indicates poor alignment of valve plunger. Replace valve.

35