32

Temperature Sensors

Overview:

The temperature sensors used in this water heater are

negative temperature co-effi cient (NTC) thermisitors.

With this type sensor, as temperature increases,

the resistance across the thermisitor decreases or

as temperature decreases, resistance will increase.

The control board monitors the resistance of each

sensor and converts each to a corresponding

temperature. There are fi ve (5) such sensors

installed on the heat pump water heater to monitor

ambient, evaporator (coil), upper tank, lower tank and

compressor discharge temperatures. Each is critical

to the operation of the unit. If there is a connection

issue with any sensor, there should be a connection

fault displayed on the User Interface Module (UIM)

Maintenance Display see “Accessing the Maintenance

Display” (p.21).

The water heater can continue to heat water with a

faulty temperature sensor, but operation will be affected

as follows:

• The unit can function with a faulty lower tank

temperature sensor. Upper tank temperature will

be used in place of average tank temperature.

• A fault with the ambient, compressor discharge

or coil (evaporator outlet) temperature sensor will

cause a HEAT PUMP fault, locking out the heat

pump. The unit will operate as if in ELECTRIC

mode until the problem is resolved and the fault is

cleared.

• An upper tank temperature sensor fault will lock

out all water heating means, both heat pump and

elements, until the problem is resolved and the

fault is cleared.

NOTE: After the problem is resolved, a fault must

be cleared by turning off power to the unit at the

breaker or fuse panel for ten (10) seconds and

then turning it back on.

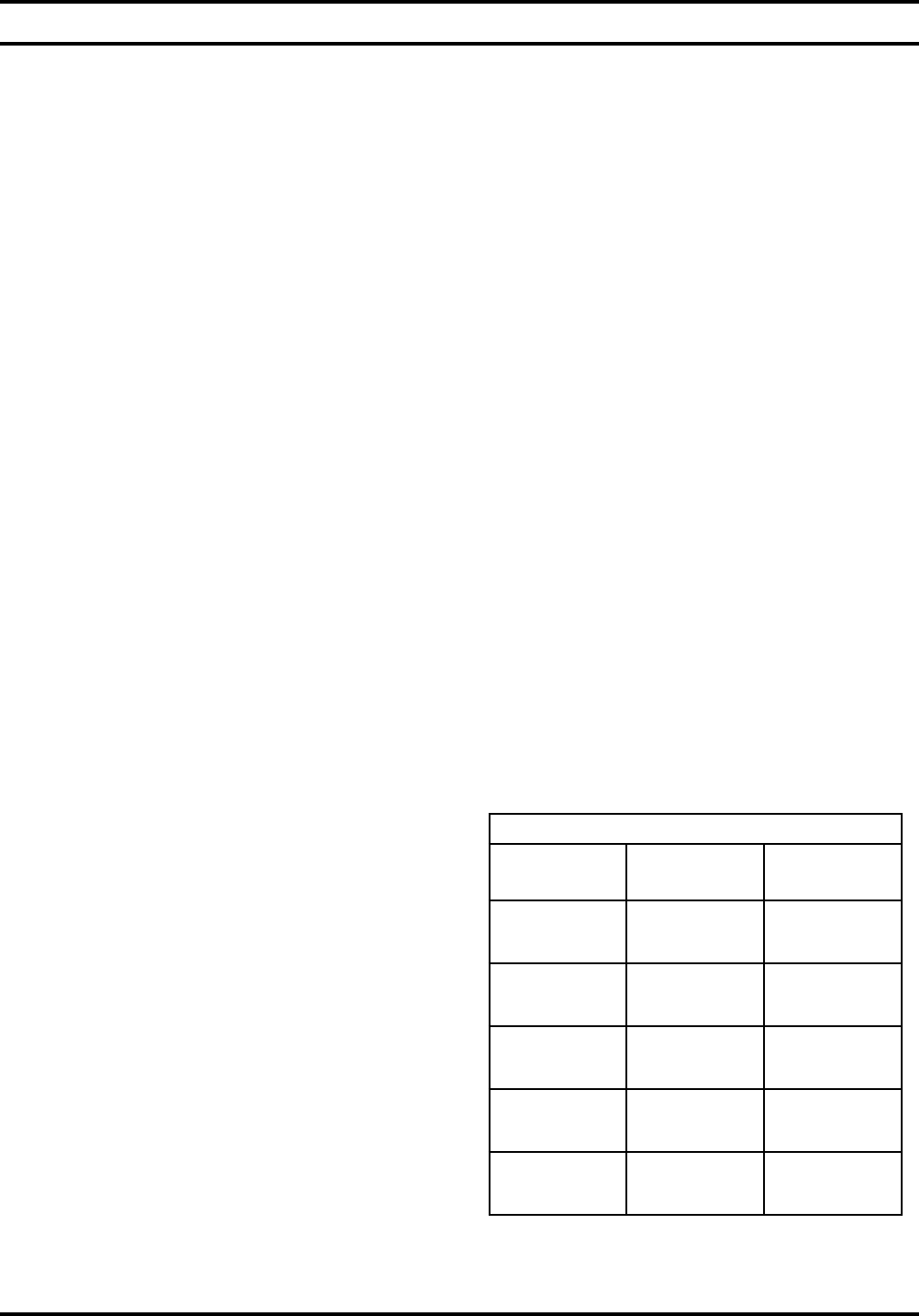

Temperature Sensor Resistance

Measurement:

If a temperature sensor connect fault is indicated by

the Maintenance Display or if a temperature sensor

issue is suspected, use the following procedure to

check the sensor(s):

1. Check the resistance of a suspect temperature

sensor by disconnecting the appropriate connector

from the control board and placing the meter leads

on the corresponding connector pins (see Table 4).

Note that there are contacts located on the side of

each connector that should be used.

2. Note the ambient temperature.

3. Compare the resistance reading on the appropriate

Resistance vs. Temperature graph for the sensor

being checked. If the reading is within ±2% of the

value obtained from the graph, the sensor is good.

If the value is outside this tolerance, the sensor

should be replaced.

A more thorough check of a sensor can be done by

checking at high and low temperature extremes. Check

at low temperature by placing the sensor in ice. The

reading should be 32°F. High temperature can be

checked also, but do not exceed 130°F for the ambient

sensor. All other sensors can be checked up to the

boiling point (212°F). Submerge only the end of the

sensor in boiling water; do not submerge the wire.

TABLE 5

Sensor Connector /

Pins

Chart

Ambient CN212

Pins 1 to 2

Chart #1

Coil-

Evaporator

CN212

Pins 5 to 6

Chart #1

Tank-Upper CN204

Pins 1 to 2

Chart #2

Tank-Lower CN204

Pins 3 to 4

Chart #2

Discharge-

Compressor

CN212

Pins 3 to 4

Chart #2