5

(c) In addition to air needed for combustion, process air

shall be provided as required for: cooling of equipment or

material, controlling dew point, heating, drying, oxidation or

dilution, safety exhaust, odor control, and air for compres-

sors.

(d) In addition to air needed for combustion, air shall be

supplied for ventilation, including all air required for comfort

and proper working conditions for personnel.

(e) While all forms of building construction cannot be

covered in detail, air for combustion, ventilation and dilution

of flue gases for gas utilization equipment vented by natural

draft normally may be obtained by application of one of the

methods covered in 5.3.3 and 5.3.4.

(f) Air requirements for the operation of exhaust fans,

kitchen ventilation systems, clothes dryers, and fireplaces

shall be considered in determining the adequacy of a space

to provide combustion air requirements.

5.3.2 Equipment Located in Unconfined Spaces: In

unconfined spaces (see definition below) in buildings,

infiltration may be adequate to provide air for combustion

ventilation and dilution of flue gases. However, in buildings

of tight construction (for example, weather stripping, heavily

insulated, caulked, vapor barrier, etc.), additional air may

need to be provided using the methods described in 5.3.3-

b or 5.3.4.

Space, Unconfined. For purposes of this Code, a space

whose volume is not less than 50 cubic feet per 1,000 BTU

per hour of the aggregate input rating of all appliances

installed in that space. Rooms communicating directly with

the space in which the appliances are installed through

openings not furnished with doors, are considered a part of

the unconfined space.

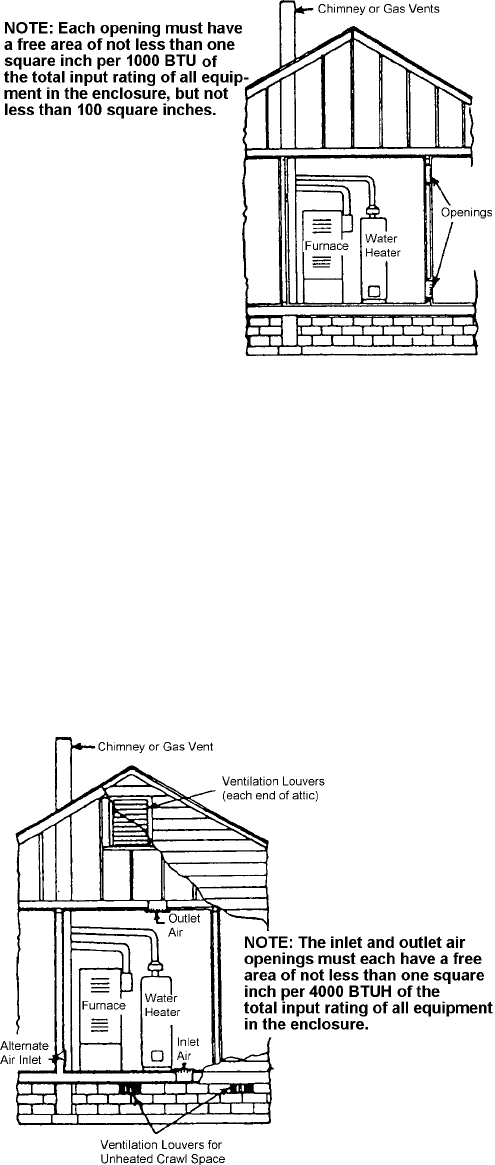

5.3.3 Equipment Located in Confined Spaces: (a)

All Air

from Inside the Building:

The confined space shall be

provided with two permanent openings communicating

directly with an additional room(s) of sufficient volume so

that the combined volume of all spaces meets the criteria

for an unconfined space. The total input of all gas utilization

equipment installed in the combined space shall be consid-

ered in making this determination. Each opening shall have

a minimum free area of 1 square inch per 1,000 BTU per

hour of the total input rating of all gas utilization equipment

in the confined space, but not less than 100 square inches.

One opening shall be within 12 inches of the top and one

within 12 inches of the bottom of the enclosure. (Figure 1 )

Figure 1

Equipment Located in Confined Spaces; All

Air from Inside Building. See 5.3.3-a

.

(b)

All Air from Outdoors:

The confined space shall be

provided with two permanent openings, one commencing

within 12 inches of the top and one commencing within 12

inches of the bottom of the enclosure. The openings shall

communicate directly, or by ducts, with the outdoors or

spaces (crawl or attic) that freely communicate with the

outdoors.

1. When directly communicating with the outdoors, each

opening shall have a minimum free area of 1 square

inch per 4,000 BTU per hour of total input rating of all

equipment in the enclosure (Figure 2).

Figure 2

Equipment Located in Confined Spaces; All

Air from Outdoors—Inlet Air from Ventilated

Crawl Space and Outlet Air to Ventilated

Attic. See 5.3.3-b

2. When communicating with the outdoors through verti-

cal ducts, each opening shall have a minimum free area

of 1 square inch per 4,000 BTU per hour of total input

rating of all equipment in the enclosure (See Figure 3).