16

Sizing Between Single or Second Stage Regulator and Appliance*

Maximum Propane Capacities Listed are Based on 1/2" W.C. pressure drop at 11" W.C. setting.

Capacities in 1,000 BTU/hour.

Pipe or

Nominal Pipe Size

Tubing Tubing Size, O.D. Type L

Schedule 40

Length, 3/8" 1/2" 5/8" 3/4" 7/8" 1-1/8" 1/2" 3/4" 1" 1-1/4" 1-1/2"

Feet

10 39 92 199 329 501 935 275 567 1,071 2,205 3,307

20 26 62 131 216 346 630 189 393 732 1,496 2,299

30 21 50 107 181 277 500 152 315 590 1,212 1,858

40 19 41 90 145 233 427 129 267 504 1,039 1,559

50 18 37 79 131 198 376 114 237 448 913 1,417

60 16 35 72 121 187 340 103 217 409 834 1,275

80 13 29 62 104 155 289 89 185 346 724 1,066

100 11 26 55 90 138 255 78 162 307 630 976

125 10 24 48 81 122 224 69 146 275 567 866

150 9 21 43 72 109 202 63 132 252 511 787

200 8 19 39 66 100 187 54 112 209 439 665

250 8 17 36 60 93 172 48 100 185 390 590

*Data in accordance with NFPA pamphlet NO. 54

WARNING

To prevent death, serious personal injury

or property damage due to fire or explosion

caused by a propane gas leak, install a gas

detecting warning device.

WARNING

If the propane gas furnace is installed in a

basement, an excavated area or a confined

space, a warning device is required due to:

• Propane gas is heavier than air and any

leaking gas can settle in any low areas

or confined spaces.

• Propane gas odorant may fade, making

the gas undetectable except with a

warning device.

If the presence of gas is suspected, follow

the instructions on Page 2 of this manual.

VIl. Electrical Wiring

WARNING

To prevent death or personal injury due to

electric shock, disconnect electrical power

before changing any electrical wiring.

CAUTION

When servicing controls, label all wires

before disconnecting. Wiring errors can

cause improper and dangerous operation.

After servicing is completed, always verify

proper operation.

The unit wiring harness is an integral part of the furnace.

Field alteration to comply with electrical codes should not

be required.

Power supply to the furnace must be NEC Class 1, and

must comply with all applicable codes. The furnace must be

electrically grounded in accordance with the local codes or,

in their absence, with the latest edition of the National

Electrical Code, ANSI NFPA No. 70 and/or the CSA C22. 1

Electrical Code. A fused disconnect must be provided and

sized in accordance with the unit maximum overcurrent

protection.

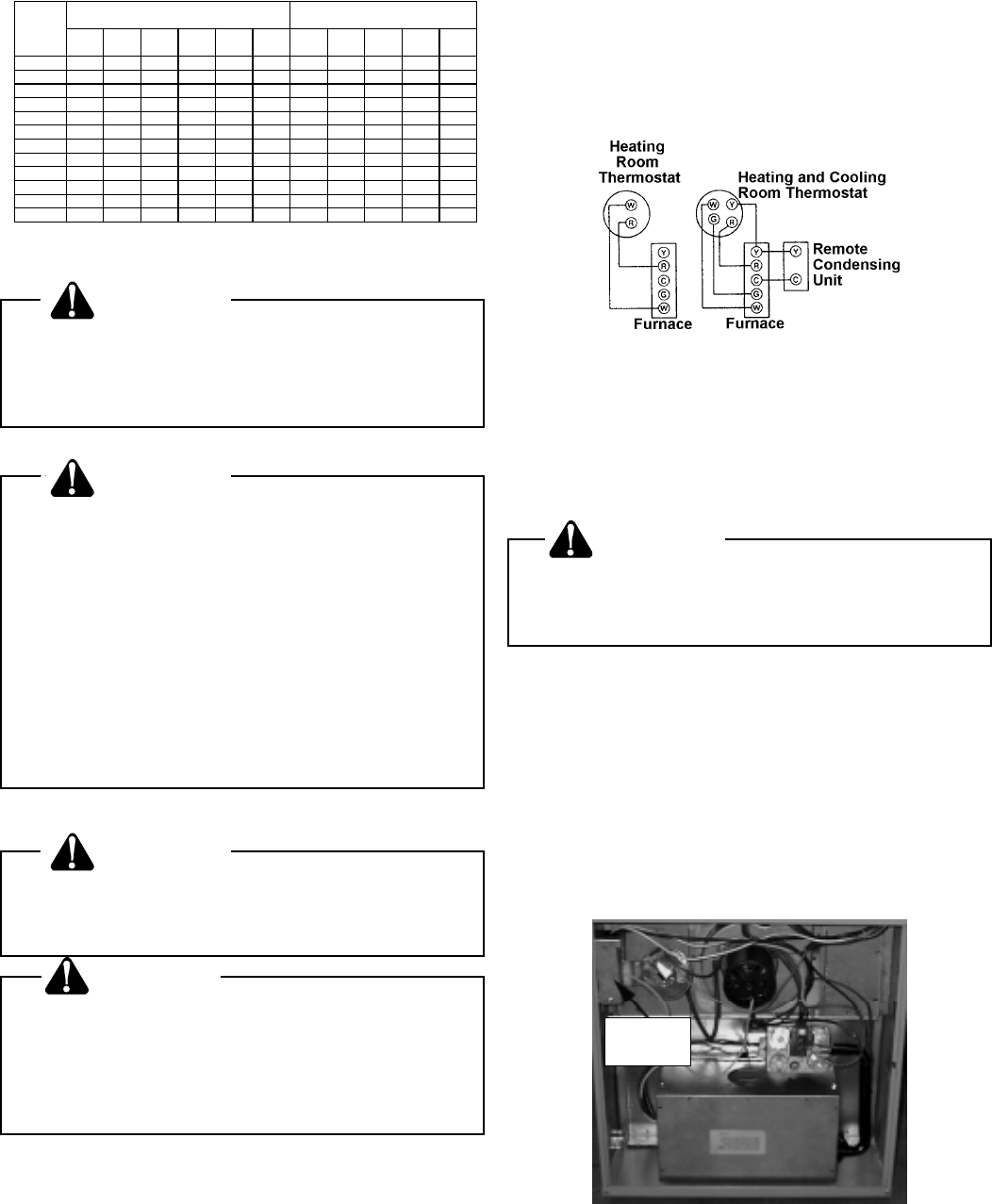

Figure 20

Typical Field Wiring

(24 VAC Control Circuit)

A 40 VA transformer and an integrated electronic control

are built into the furnace to allow use with most cooling

equipment.

CAUTION

To avoid the risk of electrical shock, wiring

to the unit must be properly polarized and

grounded.

To provide more reliable sensing of flame, the

ground wire

must run to the electrical panel.

Line voltage wiring

must enter into the junction box pro-

vided with the furnace.

As shipped, the junction box is attached to the left side of

the furnace (as viewed for an upflow installation). If this is

suitable for your installation, no changes are necessary.

If the line voltage wiring is to enter through the right side of

the furnace (as viewed for an upflow installation), relocate

the junction box as shown in Figure 21.

Figure 21

Junction Box (Left Side)

Junction

Box