4 YORK INTERNATIONAL

SECTION 1

DESCRIPTION OF SYSTEM AND FUNDAMENTALS OF OPERATION

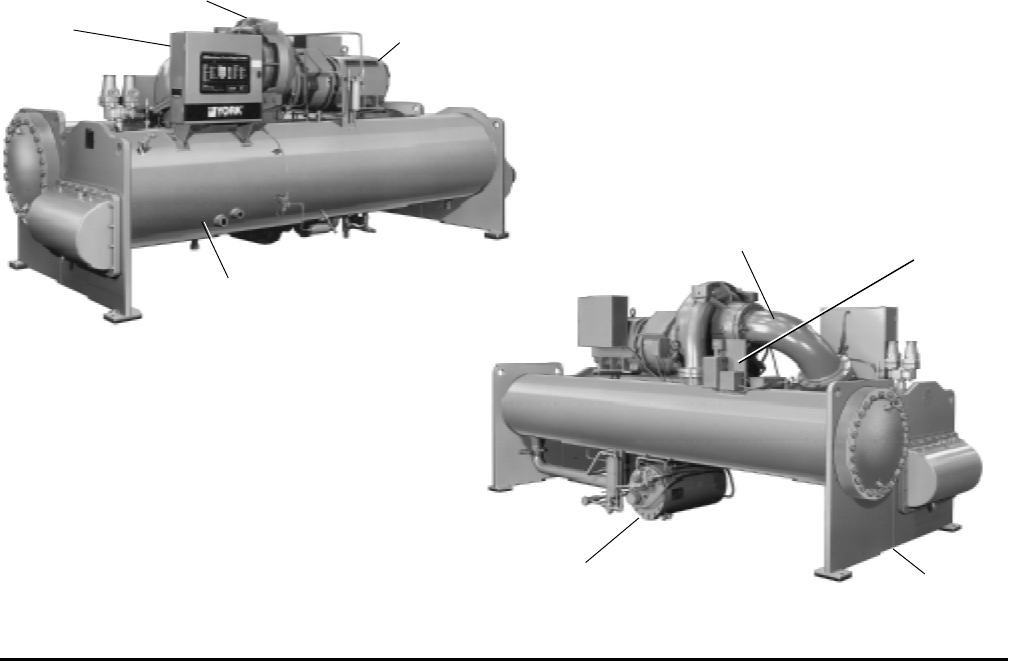

FIG. 1 – MODEL YK MILLENNIUM CHILLER

SYSTEM OPERATION DESCRIPTION (See Fig. 2)

The YORK Model YK Millennium Chiller is commonly

applied to large air conditioning systems, but may be

used on other applications. The chiller consists of an

open motor mounted to a compressor (with integral

speed increasing gears) condenser, cooler and flow

control chamber.

The chiller is controlled by a modern state of the art

MicroComputer Control Center which monitors its op-

eration. The Control Center is programmed by the op-

erator to suit job specifications. Automatic timed start-

ups and shutdowns are also programmed to suit

nighttime, weekends, and holidays. The operating sta-

tus, temperatures, pressures, and other information per-

tinent to operation of the chiller are automatically dis-

played and read on a 40 character alphanumeric

message display. Other displays can be observed by

pressing the keys as labeled on the Control Center.

The chiller with the MicroComputer Control Center is

applied with an electro-mechanical starter, YORK Solid

State Starter (optional), or Variable Speed Drive (op-

tional).

In operation, a liquid (water or brine to be chilled) flows

through the cooler, where boiling refrigerant absorbs

heat from the water. The chilled liquid is then piped to

fan coil units or other air conditioning terminal units,

where it flows through finned coils, absorbing heat from

the air. The warmed liquid is then returned to the chiller

to complete the chilled liquid circuit.

The refrigerant vapor, which is produced by the boiling

action in the cooler, flows to the compressor where the

rotating impeller increases its pressure and tempera-

ture and discharges it into the condenser. Water flowing

through the condenser tubes absorbs heat from the re-

frigerant vapor, causing it to condense. The condenser

water is supplied to the chiller from an external source,

usually a cooling tower. The condensed refrigerant drains

from the condenser into the flow control chamber, where

the flow restrictor meters the flow of liquid refrigerant

to the cooler to complete the refrigerant circuit.

The major components of a chiller are selected to handle

the refrigerant which would be evaporated at full load

CONTROL

CENTER

COMPRESSOR

MOTOR

COOLER

27382A

DISCHARGE LINE

PRE-ROTATION

VANE

ACTUATOR

CONDENSER

OIL RESERVOIR/

PUMP

27385A