YORK INTERNATIONAL

70

PRINT Key

The PRINT key allows the operator to obtain a printout

of real-time system operating data or a printout of sys-

tem data at the “instant of the fault” on the last six faults

which occurred on the unit. An optional printer is re-

quired for the printout.

See Service And Troubleshooting sec-

tion for Printer Installation informa-

tion.

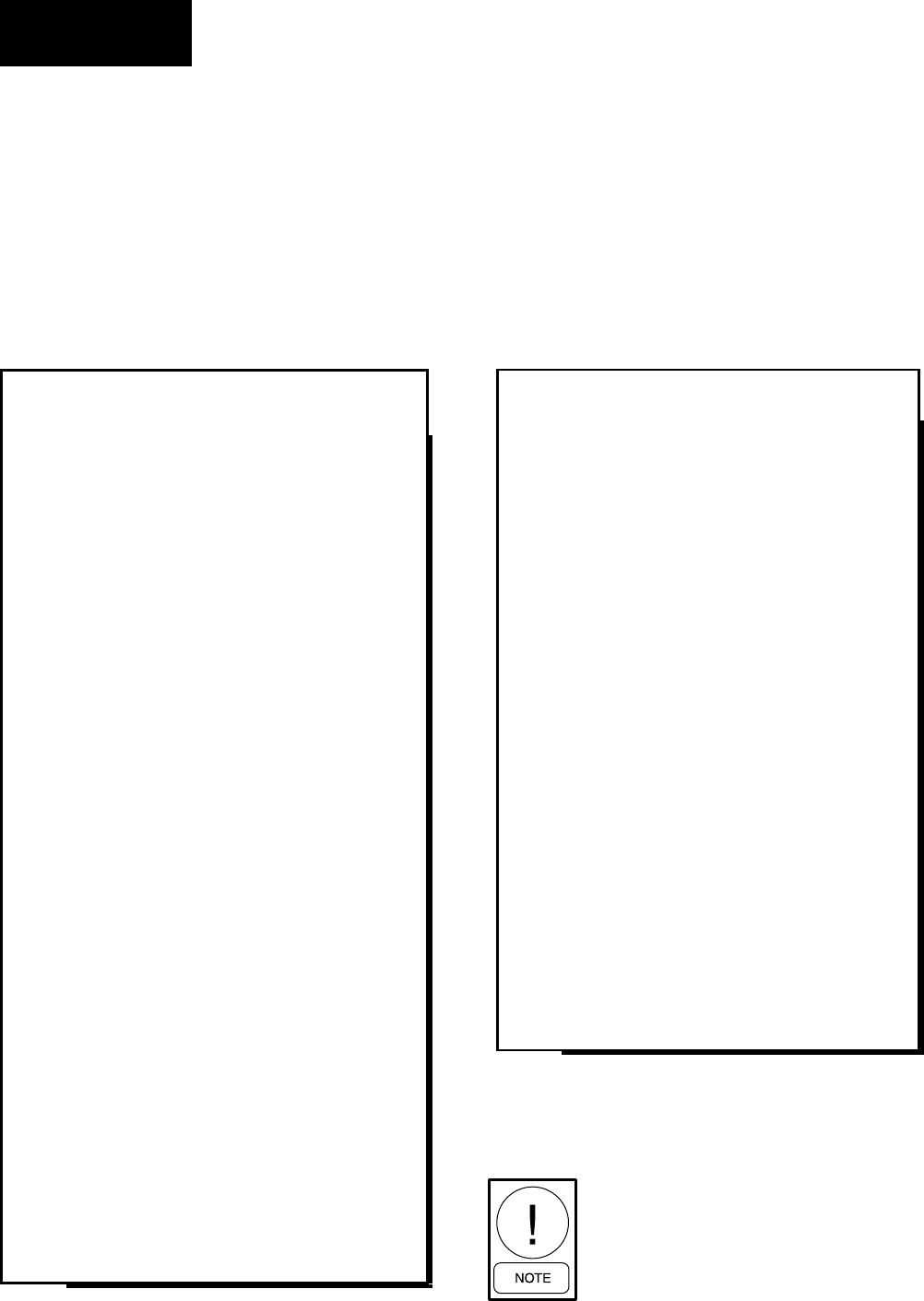

YORK INTERNATIONAL CORPORATION

MILLENNIUM LIQUID CHILLER

UNIT STATUS

2:04PM 01 JAN 99

SYS 1 NO COOLING LOAD

SYS 2 COMPRESSORS RUNNING 2

OPTIONS

CHILLED LIQUID WATER

AMBIENT CONTROL STANDARD

LOCAL/REMOTE MODE REMOTE

CONTROL MODE LEAVING LIQUID

LEAD/LAG CONTROL AUTOMATIC

FAN CONTROL AMB & DSCH PRESS

PROGRAM VALUES

DSCH PRESS CUTOUT 395 PSIG

SUCT PRESS CUTOUT 44 PSIG

LOW AMBIENT CUTOUT 25.0 DEGF

LEAVING LIQUID CUTOUT 25.0 DEGF

ANTI RECYCLE TIME 600 SECS

FAN CONTROL ON PRESS 230 PSIG

FAN DIFF OFF PRESS 80 PSIG

NUMBER OF COMPRESSORS 6

UNIT DATA

RETURN LIQUID TEMP 58.2 DEGF

LEAVING LIQUID TEMP 53.0 DEGF

DISCHARGE AIR TEMP 55.3 DEGF

COOLING RANGE 42.0 +/- 2.0 DEGF

SYS 1 SETPOINT 70 +/- 3 PSIG

SYS 2 SETPOINT 70 +/-3 PSIG

AMBIENT AIR TEMP 74.8 DEGF

LEAD SYSTEM SYS 2

EVAPORATOR PUMP ON

EVAPORATOR HEATER OFF

ACTIVE REMOTE CONTROL NONE

SOFTWARE VERSION C.M02.01.00

SYSTEM 1 DATA

COMPRESSORS STATUS OFF

RUN TIME 0- 0- 0- 0 D-H-M-S

SUCTION PRESSURE 66 PSIG

DISCHARGE PRESSURE 219 PSIG

SUCTION TEMPERATURE 52.8 DEGF

LIQUID LINE SOLENOID OFF

HOT GAS BYPASS VALVE OFF

CONDENSER FAN STAGES OFF

SYSTEM 2 DATA

COMPRESSORS STATUS 2

RUN TIME 0- 0- 1-46 D-H-M-S

SUCTION PRESSURE 51 PSIG

DISCHARGE PRESSURE 157 PSIG

LIQUID LINE SOLENOID ON

CONDENSER FAN STAGES 3

DAILY SCHEDULE

S M T W T F S *=HOLIDAY

MON START=00:00AM STOP=00:00AM

TUE START=00:00AM STOP=00:00AM

WED START=00:00AM STOP=00:00AM

THU START=00:00AM STOP=00:00AM

FRI START=00:00AM STOP=00:00AM

SAT START=00:00AM STOP=00:00AM

HOL START=00:00AM STOP=00:00AM

Unit Controls

OPERATING DATA PRINTOUT

Pressing the PRINT key and then OPER DATA key al-

lows the operator to obtain a printout of current

systemoperating parameters. When the OPER DATA

key is pressed, a snapshot will be taken of system op-

erating conditions and panel programming selections.

This data will be temporarily stored in memory and trans-

mission of this data will begin to the printer. A sample

Oper Data printout is shown below.