LIMITATIONS

These units must be installed in accordance with national and

local or municiple safety codes: Refer to Table 1 for Unit

Application Data.

If components are to be added to a unit to meet local codes, they

aretobeinstalledat thedealer'sand/or thecustomer'sexpense.

LOCATION

Use the following guidelines to select a suitable location for

these units.

1. Unit is designed for outdoor installation only.

2. Outdoor coil must have an unlimited supply of air.

3. For ground level installation, use a level concrete slab with

a minimum thickness of 102mm (4 in.). The length and

width should be at least 152mm (6 in.) greater than the unit

base rails. Do not tie slab to the building foundation.

4. Roofstructures must be able to support the weight of the unit

and its options and / or accessories. Unit must be installed on

a solid level roof curb or appropriate angle iron frame.

CAUTION: If a unit is to be installed on a roof curb or special frame

other than a YORK roof curb, gasketing must be applied

toallsurfacesthat comeincontactwiththeunitunderside.

5. Maintain level tolerance to 13mm (

in.) maximum across

the entire length or width of the unit.

6. Elevate the unit sufficiently to prevent any blockage of the

airentrances by snow inareas where therewill be snowac

-

cumulation. Check the local weather bureau for the ex

-

pected snow accumulation in your area.

OUTDOOR COIL CONDENSATE DRAINAGE PRECAUTION

Condensatedrainsfrom theoutdoorcoilduring theheatingand

defrost cycles. Normally this condensate may be allowed to

drain directly onto the ground/roof. A gravel bed is

recommended to prevent mud splashing.

WARNING:Theunit should not be installed in an area where mud

or ice could cause personal injury. Remember that

condensate drips from the outdoor coil during heat

and defrost cycles and that this condensate freezes

when the temperature of the outdoor air is below 0°C

(32

F).

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. Rig the

unit by attaching chain or cable slings to the lifting holes

provided in the base rails. Spreaders, whose length exceeds

the largest dimension across the unit, MUST be used across

the top of the unit.

BEFORE LIFTING A UNIT, MAKE SURE THAT ITS WEIGHT

IS DISTRIBUTED EQUALLY ON THE CABLES SO THAT IT

WILL LIFT EVENLY.

Units may also be moved or lifted with a forklift. Slotted

openings in the base rails are provided for this purpose.

LENGTH OF FORKS MUST BE A MINIMUM OF 1067mm

(42 in.).

Remove the nesting brackets from the four corners on top of

the unit. All screws that are removed when taking these

brackets off must be replaced on the unit.

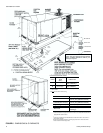

RefertoTable3for unitweightsandtoFigure 1forapproximate

center of gravity.

CLEARANCES

All units require certain clearances for proper operation and

service. Refer to Figure 6 for the clearances required for

combustibleconstruction,servicing,and properunitoperation.

WARNING:Do not permit overhanging structures or shrubs to

obstruct outdoor air discharge outlet.

DUCTWORK

A closed return duct system shall be used. This does not

preclude use of economizers or outdoor fresh air intake. The

supply and return air duct connections at the unit should be

madewithflexiblejointsto minimizethetransmissionofnoise.

The supply and return air duct systems should be designed for

theairflow andstaticrequirementsof thejob. TheyshouldNOT

be sized to match the dimensions of the duct connections on

the unit.

CAUTION: When fastening ductwork to the side duct flanges

on the unit, insert the screws through the duct

flanges only. DO NOT insert the screws through

the casing.

Outdoor ductwork must be insulated and water

-

proofed.

Refer to Figure 6 for information concerning side and bottom

supply and return air duct openings.

FILTERS

Each unit is supplied with 25mm (1 in.) filters . Replacement

51mm (2 in.) filters may be used without modification to the

filter racks. Filters must always be installed ahead of the

evaporator coil and must be kept clean or replaced with same

035-12984-001-A-0204

Unitary Products Group 3

INSTALLATION

FIG. 1 - CENTER OF GRAVITY

2089

“

1035

“

1140

“

502

“

APPROXINATE

CENTER OF

GRAVITY

FRONT

BACK

CONDENSER

COIL END

Voltage Variation

Min. / Max.

342 / 457

Cooling

Wet Bulb Temperature of Air

on Indoor Coil, Min./Max.

°C 14 / 22

°F 57 / 72

Dry Bulb Temperature of Air

on Outdoor Coil, Min./Max.

°C 7 / 49

°F 45 / 120

Heating

Minimum Dry Bulb Temperature

of Air on Outdoor Coil

°C -23

°F -10

TABLE 1 - UNIT APPLICATION DATA