During troubleshooting, the defrost time can be reduced to 20

seconds by shorting out the SW1 test pegs on the module. The

pegs are 13mm (

in.) long, 1mm ( in.) apart and are

mounted on a white base. See Figure 8.

LOCKOUT CONTROL

Any one of four conditions will put the system into a lock-out

condition during the heating or cooling mode:

1.

The discharge line temperature reaches 124°C (255°F)

(102°C [215°F] reset) or,

2. The discharge pressure reaches 2770 kPa (398 PSIG)

(2158 kPa [310 PSIG] reset) or,

3.

The suction line freezestat equals -3°C (26°F) (3°C [38°F]

reset) or,

4. The low-pressure cut-out equals 49 kPa (7 PSIG) (153 kPa

[22 PSIG] reset).

A lock-outl energizes the emergency heat light on the

thermostat and the red LED light on the unit relay board.

Turning the thermostat switch to “Off” then back to “On”, will

reset the system.

NOTICE TO OWNER:

If a lockout occurs, check for the following problems before

calling a serviceman:

1. Dirty filters.

2. Snow accumulation.

3. Leaf or debris blockage.

After eliminating the problem, attempt to restart the system as

follows:

•

turn the system switch on the thermostat to its “OFF”

position for 10 seconds.

•

turn it back to its original position.

If the unit doesn't start, call a serviceman.

NOTE: Models with an anti-recycle accessory will have a 5-

minute delay before starting.

CHECKING SUPPLY AIRFLOW

The speed of the supply air blower will depend on the required

airflow, the unit accessories and the static resistances of both

the supply and the return air duct systems. With this

information, the speed for the supply air blower can be

determined from the blower performance and static resistance

data on Tables 4, 5 and 7.

Knowing the required blower RPM and the blower motor kW

(HP), the speed setting for the supply air motor can be

determined.

The setting (turns open) for the optional belt-drive supply air

pulley can be determined from Table 10.

OPTIONAL BELT-DRIVE BLOWER

All unitswith belt-drive blowers have single speed motors.The

variable pitch pulley on the blower motor can be adjusted to

obtain the desired supply airflow. Refer to Table 6 for blower

motor drive data. The tension on the belts should be adjusted

as shown in Figure 9.

Startthe supplyair blower motor.Adjust theresistances inboth

the supply and the return air duct systems to balance the air

distribution throughout the conditioned space. The job

specifications may require that this balancing be done by

someone other than the equipment installer.

To check the supply airflow after the initial balancing has been

completed:

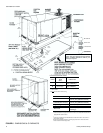

1. Drill two 8mm ( in.) holes in the side panels as shown in

Figure 10.

2. Insert at least 203mm (8 in.) of 6mm (

in.) tubing into each

of these holes for sufficient penetration into the air flow on

both sides of the indoor coil.

NOTE: The tubes must be inserted and held in a position per

-

pendiculartothe airflowsothat velocitypressuredoes

not affect the static pressure readings.

035-12984-001-A-0204

Unitary Products Group 13

TURNS

OPEN*

BLOWER DRIVE RANGE (RPM)

060

5

4

3

2

1

0

850

916

982

1048

1114

1180

*Pulley can be adjusted in half-turn increments.

TABLE 10 - BELT-DRIVE SUPPLY AIR

MOTOR PULLEY ADJUSTMENT

FIG. 9 - BELT ADJUSTMENT

FIG. 10 - HOLE LOCATIONS (PRESS. DROP READING)

419

“

435

“

533

21"

“ HOLES

DUCT FLANGES

(Back of Unit)

DAMPER

ASSEMBLY

FILTERS

INDOOR

COIL

FRONT OF UNIT

L.H. END VIEW

(Filter Access End)