screw fully clockwise and then energize and de-energize

terminals “R” to “G”. With terminals “R” to “G” energized,

turn the minimum position screw counterclockwise until the

desired minimum position has been attained.

11. Replace the filter section access panel.

COOLING SYSTEM

The unit has an air-cooled condenser and is factory-charged

with Refrigerant-22.

The compressor is hermetically sealed, internally sprung,

mounted on spring isolators and inherently (internally)

protected. If there is an abnormal temperature rise in the

compressor,theprotectoropensto shutdownthecompressor.

PRELIMINARY OPERATION COOLING

After the installation has been completed, the crankcase

heaterof thecompressormust beenergized foratleast 4hours

before starting the unit. After this initial warm-up, the

compressor should be given three false starts (energized just

long enough to make a few revolutions) with a 5 minute delay

between each start before being put into full time service.

NOTE: Prior to each cooling season, the crankcase heater

must be energized at least 10 hours before the system

is put into operation.

COOLING SEQUENCE OF OPERATION

When the thermostat calls for cooling, the compressor and the

outdoor fan motor will be energized through terminal “Y1" and

the supply air blower motor will be energized through terminal

”G" (if the fan switch on the subbase is set in the “AUTO”

position). The supply air blower motor will run continuously if

the fan switch is set in the “ON” position.

The reversing valve is energized thru the “O” circuit when the

subbase is in the cooling mode.

HEATING SEQUENCE OF OPERATION

The following sequence of operation is based on using a

standardYORKheatpumpthermostatwithtwo heatingstages.

FIRST STAGE HEAT

When the thermostat calls for heating, the compressor and the

outdoor fan motor will be energized through terminal “Y1" and

the supply air blower motor will be energized through terminal

”G" (if the fan switch on the subbase is set in the “AUTO”

position). The supply air blower motor will run continuously if

the fan switch is set in the “ON” position.

SECOND STAGE HEAT

If compressor operation can not satisfy the heating

requirements, second stage heat will energize supplemental

electric heat (if supplied) thru the “W1" circuit.

DEFROST SEQUENCE OF OPERATION

The BCH has a unique “ambient modified” time-temperature

defrost control that automatically adjusts to changes in the

outdoor temperature. The defrost control will shorten the

defrost initiation time periods above 2°C (35°F) and will extend

the defrostinitiation time periodsbelow 2°C (35°F).The control

is factory set to defrost at 110 minutes (T3), but it can be field

adjusted to defrost at 80 minutes (T2) or 50 minutes (T1) in

areas with high humidity.

The curve in Figure 7 shows how defrost initiation times are

automatically compensated for changes in outdoor

temperature.

EXAMPLE: If the time is factory set on pin T-3 (110 minutes at

2°C(35°F) outdoor)andthe outdoortemperature climbsto 7°C

(45°F), the time initiation cycle decreases to 100 minutes.

If the outdoor temperature drops to -12°C (10°F) where ice is

less likely to form, the 110 minute interval increases to 150

minutes.

Two requirements must be met before a defrost cycle can be

initiated.

1. The defrost time cycle must be complete.

2. The liquid line temperature must be less than -2°C (28°F).

Defrost terminates when the liquid line sensor reaches 13°C

(55°F) or after 10 minutes.

The defrost time cycle restarts 10 minutes after the start of the

defrost cycle even though the liquid sensor terminated defrost

after 3 minutes.

035-12984-001-A-0204

12 Unitary Products Group

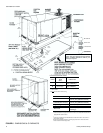

FIG. 7 - DEFROST INITIATION TIMES

FIG. 8 - AMBIENT MODIFIED TIME/TEMPERATURE

CONTROL

T1 - 50 Minute Setting

T3 - 110 Minute Setting (Factory Set Point)

T2 - 80 Minute Setting

200

-10

0

10

20

30

40

50

250

150

100

50

0

60

OUTDOOR AMBIENT, DEG. F

TIME BETWEEN DEFROST CYCLES, MINUTES

OPERATION

T1 - 50 MINUTE SETTING

T2 - 80 MINUTE SETTING

T3 - 110 MINUTE SETTING

(Factory Set Point)

SHORTING PEGS TO

OVERRIDE TIMER

FOR SERVICE

MOVABLE JUMPER

WIRE TO CHANGE

DEFROST TIMER