18

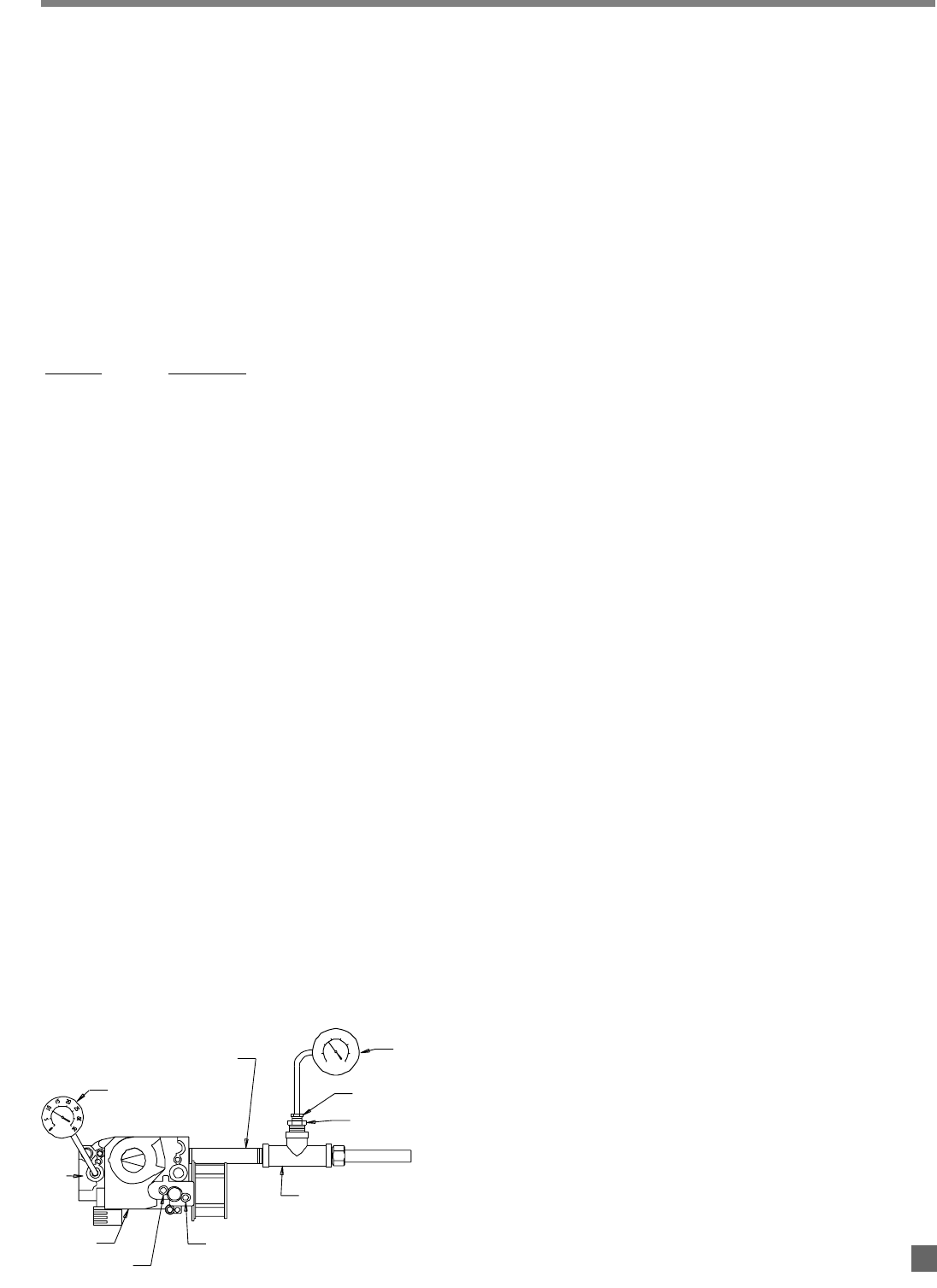

GAUGE 00764

NIPPLE, 1/2 IN

LO

HI

TEE, 1/2 IN

BUSHING, 1/4 IN X 1/8 IN

BUSHING, 1/2 IN X 1/4 IN

GAS CONTROL

GAUGE 00764

OFF

ON

OUTLET

PRESSURE

TAP

0

5

10

20

25

30

35

15

ATTENTION

■

The following explains a typical procedure to be followed

in checking gas pressures.

■ Consult the dataplate on the heater or page 4 in this

manual for specific pressures to be used in conjunction

with this procedure. The gas pressures will vary

depending upon fuel type.

■ Gas pressure measured at the inlet to the gas valve is

Inlet Pressure and gas pressure measured at the outlet

of the gas valve is Burner Manifold Pressure.

MATERIALS REQUIRED

(To be secured through local purchase)

QQuuaannttiittyy DDeessccrriippttiioonn

2 Gas pressure gauges capable of reading

up to 35 in. W.C. (may also be ordered

from L.B. White, part number 00764)

1 1/2 in. Tee

1 Bushing, 1/2 in. x 1/4

1 Bushing, 1/4 in. x 1/8

A. PPreparation

1. Disconnect the heater from the electrical supply and

close the fuel supply valve to the heater inlet.

2. Remove gas hose and sediment trap from heater.

3. Assemble the hardware components together as

shown in Fig. 14.

4. Open the case access panel at gas inlet end of

heater.

5. Brush or blow off any dust or dirt in the vicinity of the

gas control valve.

B. GGauge IInstallation

1. Locate the outlet pressure tap, see Fig. 14. Remove

the pressure tap plug using a 3/16 in. allen key.

2. Securely connect a pressure gauge at this pressure

tap, and at the tee adapter at heater inlet. See Fig.

14.

3. Open the fuel supply valves to the heater, reconnect

the heater electrical supply, and start the heater.

C. RReading PPressures

1. With the heater operating, the pressure gauges

should read the pressures specified on the dataplate.

2. Do the readings at the inlet and outlet pressure

gauges agree with that specified on the dataplate?

If so, then no further checking or adjustment is

required. Proceed to section D.

3. If the inlet pressures do not agree with that specified

on the dataplate, then the regulator controlling gas

pressure to the heater requires adjustment.

4. If the inlet pressure is correct but the burner manifold

pressure does not agree with that specified on the

dataplate, then the HI and LO heat output feature of

the gas control valve requires adjustment.

5. Turn the thermostat down to its lowest setting.

Remove the cap from the HI and LO heat adjusting

screws at the two stage pressure regulator on the gas

control valve.

6. Slowly turn up the thermostat until the valve opens in

first stage position and a pressure is read of no

greater than 1.3 in. W.C. (L.P.) or .8 in. W.C. (N.G.) at

the outlet pressure gauge. If less than 1.3 in. W.C.

(L.P.) or .8 in. W.C. (N.G.) is read, the LO heat setting

at the regulator on the gas control will require

adjusting. Turn clockwise to increase, or

counterclockwise to decrease.

7. Turn the thermostat completely up. You should see

the valve open at second stage position and the gas

pressure increase from 1.3 in. W.C. (L.P.) or .8 in. W.C.

(N.G.) at first stage heat to 5.2 in. W.C. (L.P.) or 3.1 in.

W.C. (N.G.) second stage heat. If less or greater than

5.2 in. W.C. (L.P.) or 3.1 in. W.C. (N.G.), the HI heat

setting must be adjusted clockwise or

counterclockwise accordingly until proper pressure is

achieved.

D. CCompletion

1. Once the proper inlet and burner manifold pressures

have been confirmed and/or properly set, close the

fuel supply valve to the heater and allow the heater to

burn off any gas remaining in the gas supply line.

2. Disconnect the heater from its electrical supply.

3. Remove the gauges, gas hose, and tee.

4. Install pressure tap plug.

5. Reconnect sediment trap and gas hoses.

6. Open fuel supply valve. Start the heater and check

for gas leaks.

7. Set thermostat to desired temperature.

Gas Pressure Checks

FIG. 14