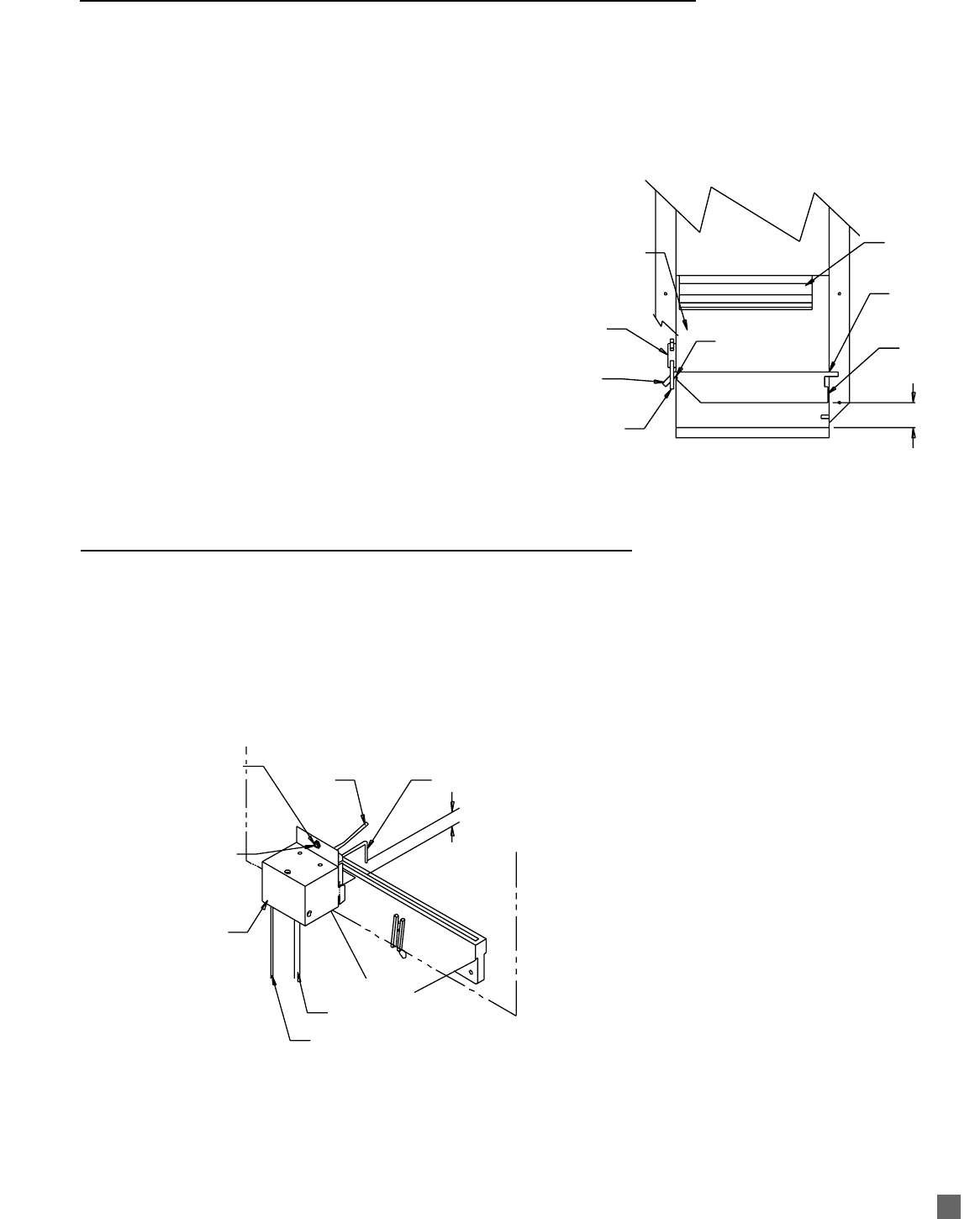

SENSOR

IGNITER

3/16 IN.

HEAT CHAMBER FACE

BURNER

IGNITER LEAD

SENSOR LEAD

ENCLOSURE

TO REMOVE IGNITER / SENSOR ASSEMBLY

REMOVE SCREW, LIFT ASSEMBLY

FROM ITS MOUNTING SLOTS

TO GAP IGNITER, LOOSEN SCREW.

MOVE ENCLOSURE UP OR DOWN

TO ALLOW PROPER POSITIONING

OF IGNITER TO BURNER.

16

1. The igniter and sensor assembly is located within a

metal enclosure on the heater chamber.

2. Remove the screw that secures the assembly to the

heat chamber and disconnect the respective leads

from the ignition control. Lift the assembly from its

mounting slots. See Fig. 11.

FIG. 11

IMPORTANT

■ The assembly may require cleaning due to

accumulations of dust and dirt over a period of time,

thereby affecting its ability to ignite fuel gas and sense

burner flame.

-- If spark appears to be weak, briskly rub the igniter

electrode with emery cloth or steel wool.

--- If the spark appears strong but the heater cycles off,

briskly rub the sensor rod with emery cloth or steel

wool.

■ Ensure the igniter gap is 3/16 in. and the igniter tip is

positioned over the burner slot according to the

illustration below.

IGNITER AND FLAME SENSOR

BLOWER OUTLET

OF HEATER

AIR PROVING

SWITCH

ARM OF

FLAPPER

AIR PROVING

SWITCH ARM

FAN WHEEL

PIVOT POINT

OF FLAPPER

EDGE OF

FLAPPER

PIVOT POINT

OF FLAPPER

FLAPPER

31.7 MM TO 34.9 MM

1. Ensure there is not any dust, dirt, etc. that may cause

binding on the pivot points of the flapper. If debris is

found, use a soft brush, or compressed air, to clean

the area as necessary.

2. The arm of the flapper should engage the arm of the

airflow switch when the trailing edge of the flapper

body is lifted and is at the proper clearance distance

off the blower housing bottom. At this distance you

will hear a click which are the contacts closing within

the switch mechanism.

3. If the switch contacts do not close within this

distance, manually push in the arm in the switch to

make sure the switch is not defective. If a click is

heard, the switch is generally considered good.

However, to ensure switch contacts do close, perform

a continuity test

4. If the switch is not defective, the flapper arm may

need adjustment to engage the switch arm.

5. Using a needle nose pliers, gently bend up the arm of

the flapper

(NOT TTHE SSWITCH AARM)

in increments

until the flapper arm engages the switch arm, closing

the contacts of the switch.

FIG. 10

clearance

1 - 1 1/4 In.

FLAPPER ADJUSTMENT