7

6. Tighten to 20 to 30 ft lbs. Use backup wrench on all wrench

flats.

NOTE: Overtightening may crush the Teflon

®

seal and cause

a leak.

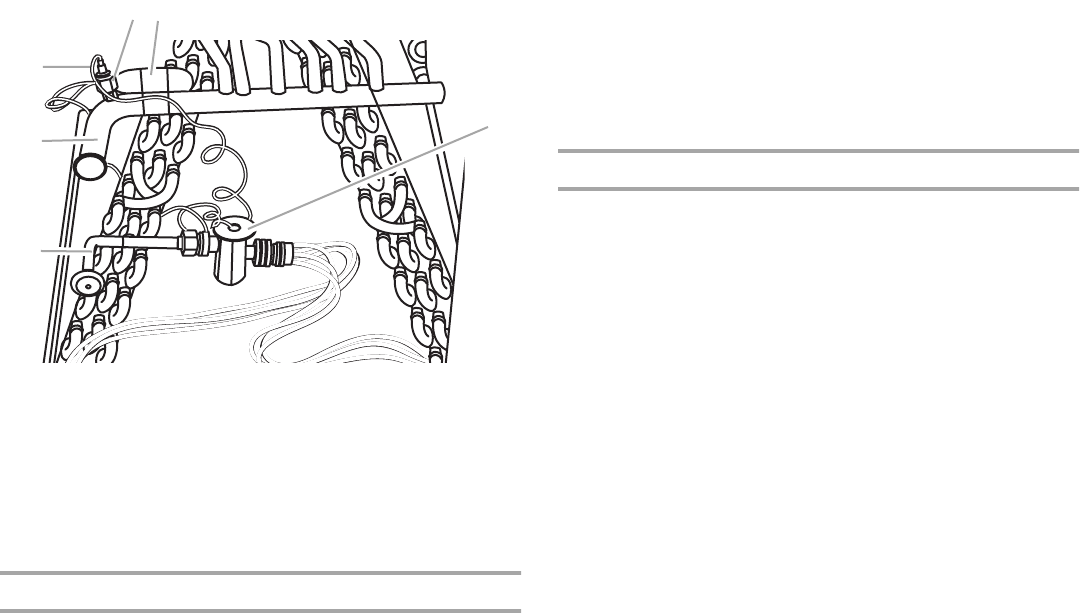

7. Connect the external equalizer line to the equalizer port on

the suction line.

8. Tighten to 8 ft lbs.

9. Attach the superheat sensing bulb to the suction header with

the strap provided with the thermal expansion valve.

NOTE: If installing a thermal expansion valve on an indoor coil

that previously used a fixed orifice, be sure to remove the existing

fixed orifice. Failure to remove a fixed orifice when installing a

thermal expansion valve to the indoor coil may result in improper

operation and damage to the system.

Connect Liquid and Suction Lines

1. Route the suction and liquid lines from the fittings on the

indoor coil to the fittings on the heat pump. Run the lines in

as direct a path as possible, avoiding unnecessary turns and

bends.

2. For product efficiency, be sure that the suction line is

insulated over the entire exposed length and that both

suction and liquid lines are not in direct contact with floors,

walls, ductwork, floor joists, or other piping.

3. Remove valve cores.

4. Wrap the service valves with a wet rag.

5. Connect the suction and liquid lines, using a brazing

compound. Braze with an alloy of silver or copper and

phosphorus with a melting point above 1,100°F.

NOTE: Do not use soft solder.

6. Make sure indoor coil has been put in place according to the

Installation Instructions and is connected to the refrigerant

lines.

7. Replace valve cores.

8. Pressurize the lines and indoor coil with a pressure not to

exceed 20 psig.

9. Leak test the lines with a pressure not to exceed 20 psig.

10. Evacuate the indoor coil and lines to a minimum of

500 microns to remove contamination and moisture, then

disconnect the vacuum pump.

11. Open the suction and liquid service valves fully.

12. Insulate the suction line with refrigerant line insulation

material of ¹⁄₄" or more wall thickness.

13. Pack insulating material around refrigerant lines where they

penetrate the structure to protect the lines and to minimize

vibration transmission.

Refrigerant Charge

Refrigerant lines must be connected by a licensed, EPA certified

refrigerant technician in accordance with established procedures.

IMPORTANT:

■ Refrigerant charge adjustment will be required for line set

lengths greater than 15 ft and for evaporator coils not

matched to the systems.

■ The heat pump is factory charged with the proper refrigerant

charge amount for a matching evaporator and 15 ft of

refrigerant line. Refer to the heat pump rating plate for the

exact amount of this factory charge.

■ Adjustment of the refrigerant charge will be necessary based

on the system combination and line length. To adjust the

refrigerant size for increased line lengths, add the following

amount of refrigerant.

For line set lengths greater than 15 ft, add refrigerant by

weighing in 0.60 oz per ft of ³⁄₈" O.D. liquid line.

■ If necessary, adjust the refrigerant charge for compatibility

with the evaporator coil.

■ In heat pump systems, horizontal suction lines should be

slightly sloped toward the heat pump. Piping must avoid dips

or low spots, which can collect oil.

Check Charge Using Normal Operating Pressures

Use Normal Operating Pressures chart to perform maintenance

checks.

NOTES:

■ The Normal Operating Pressures chart is not a procedure for

charging the system.

■ Minor variations in these pressures may be due to differences

in installations.

■ Significant deviations could mean that the system is not

properly charged or that a problem exists with some

component in the system.

A. Equalizer port

B.Superheat sensing bulb

C. Thermal expansion valve

D.Liquid line

E.Suction line

F. Equalizer line

E

F

A

B

C

D